Heat supply systems and method based on coupling phase change

A heating system and phase change technology, applied in the field of heating systems based on coupled phase change, can solve the problems of aggravating the fluctuation of the heating network, the instability of renewable energy, and the impact of stable operation, so as to reduce the energy consumption of the system and be easy to control. , the effect of strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

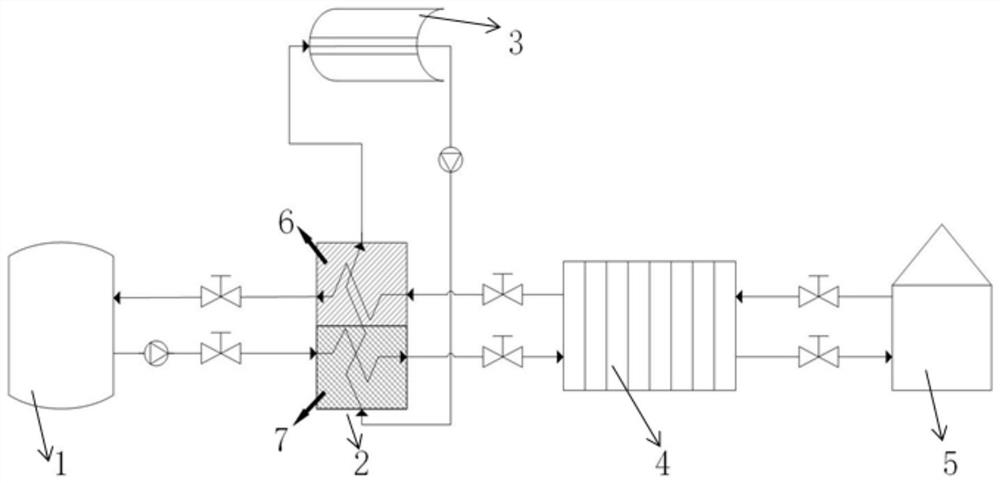

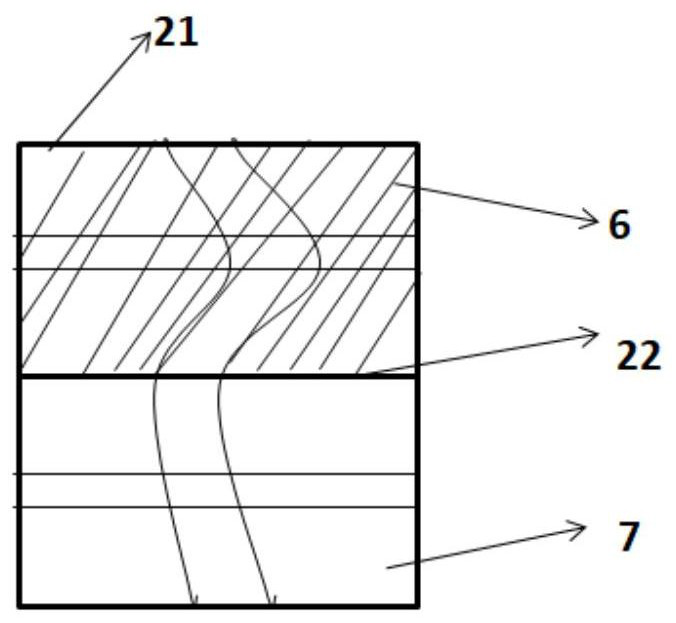

[0033] A heating system based on coupled phase transitions, such as figure 1 As shown, it includes a first water circulation loop composed of sequentially connected heat source 1, heat station 4 and heat user 5, the inlet pipeline of each heat station 4 is connected with a heat storage device 2, and the heat storage device 2 is connected with a heater 3, The outlet end of the heat station 4 is connected with the heat user 5; as figure 2 As shown, the heat storage device 2 includes a box body 21, and a partition plate 22 is arranged in the middle of the box body 21. The partition plate 22 divides the interior of the box body 21 into two areas, which are respectively the first heat preservation area 6 and the second heat preservation area. Heat preservation zone 7, the first heat preservation zone 6 and the second heat preservation zone 7 are all provided with inlet port and outlet port; They are respectively connected to the heat station 4 and the heat source 1; the first hea...

Embodiment 2

[0035] Except for the following content, all the other contents are the same as in Example 1.

[0036] The inlet port of the second thermal insulation zone 7 is connected with the outlet port of heat source 1, and the outlet port of the second thermal insulation zone 7 is connected with the inlet port of thermal station 4; The inlet port of the first thermal insulation zone 6 is connected with the outlet port of thermal station 4, The outlet end of the first heat preservation zone 6 is connected with the inlet end of the heat source 1 . Valves are arranged on the pipelines connected among the heat source 1 , the heater 3 , the heat station 4 , the heat user 5 , the first heat preservation zone 6 and the second heat preservation zone 7 . The low-temperature phase-change material is paraffin; the high-temperature phase-change material is an aqueous solution of inorganic salt.

Embodiment 3

[0038] Except for the following content, all the other contents are the same as in Example 1.

[0039] The heater 3 is installed above the heat storage device 2 . In the heat storage device 2 , the first heat preservation zone 6 is located on top of the second heat preservation zone 7 . In the water circulation loop, the outlet end of the first heat preservation zone 6 is connected to the inlet end of the heater 3 , and the outlet end of the heater 3 is connected to the inlet end of the second heat preservation zone 7 . The heater 3 is a solar heater.

[0040] A heating method based on the above-mentioned heating system, specifically:

[0041] The first water circulation loop starts to work, the valve at the outlet of heat source 1 is opened, the hot water in heat source 1 flows into the second heat preservation zone 7, and flows into the heat station 4 through the pipeline in the second heat preservation zone 7, and then flows to the heat station 4 through the heat power st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com