Steering oil cylinder pressure detection equipment

A testing equipment, steering oil cylinder technology, applied in the direction of using stable tension/pressure to test the strength of materials, measuring devices, testing of mechanical parts, etc. To achieve the effect of improving practicability and reliability, improving safety and practicability, and improving practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

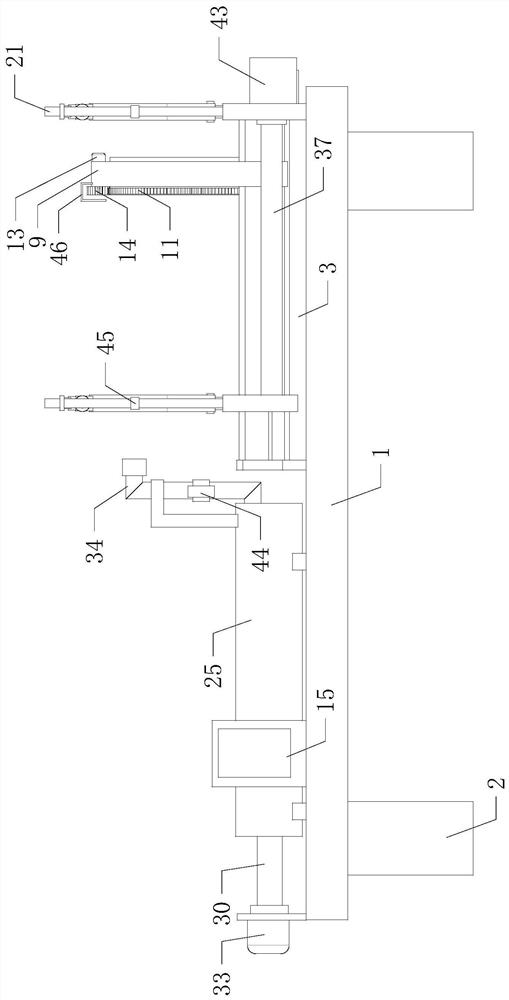

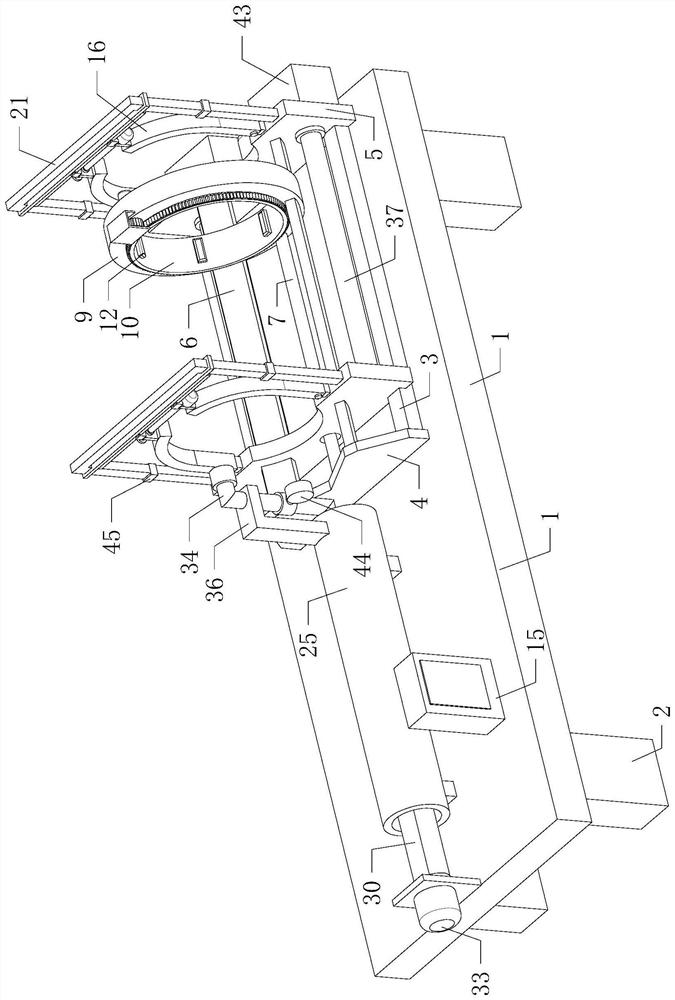

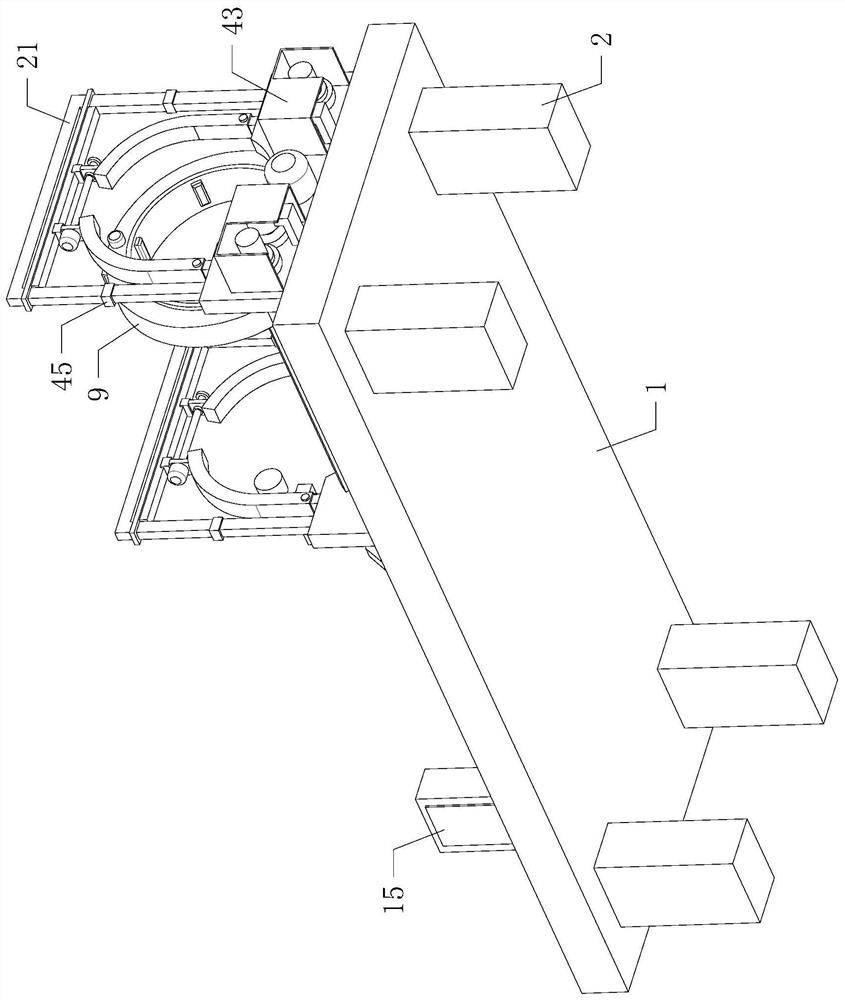

[0021] like Figure 1 to Figure 6 As shown, a steering cylinder pressure detection device of the present invention, when it is working, places the steering cylinder to be detected on two sets of second support plates 5, the cylinder passes through the rotating ring 10, the central axis of the oil cylinder and the rotating ring The axes of 10 are coaxial, and the central control box 15 controls two sets of clamping devices to tighten and fix the oil cylinder. Carry out air supply pressurization processing, when the air pressure in the oil cylinder reaches the specified value, the central control box 15 controls to open multiple sets of laser range finders 12, and the inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com