High-temperature non-coupling dual-power inductor and manufacturing method thereof

A non-coupling, dual-power technology, applied in the direction of inductance/transformer/magnet manufacturing, transformer/inductor casing, transformer/inductor coil/winding/connection, etc., can solve problems such as difficult to ensure normal use, and achieve improved shock resistance The effects of dynamic performance, high circuit adaptability, and clear device assembly form

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention proposes a high-temperature uncoupled dual-power inductor and a corresponding manufacturing method suitable for high-precision application scenarios such as servers and cloud server components, and the specific scheme is as follows.

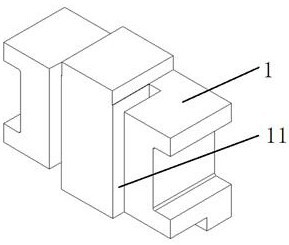

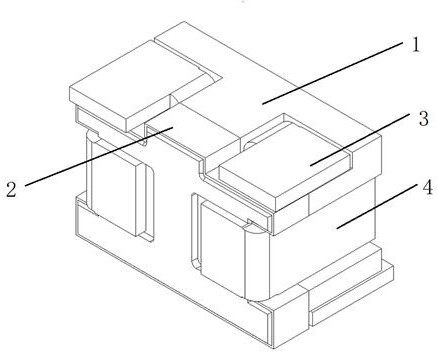

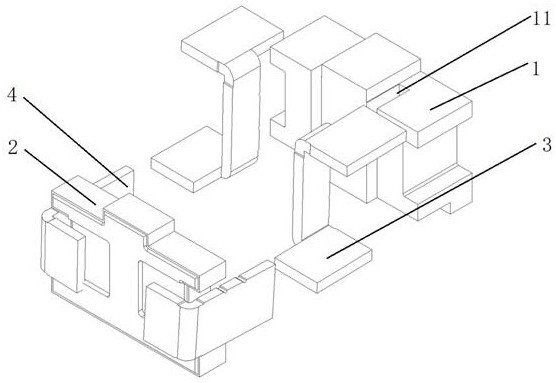

[0032] Such as Figure 1~Figure 3As shown, a high-temperature uncoupled dual-power inductor is composed of an inductor magnet and two inductor conductors 3. The inductor magnet includes a molded inductor body 1 and a molded inductor cover plate 2. The molded inductor body 1 and Both of the formed inductance cover plates 2 are integrally formed and fixed together, the formed inductance main body 1 is provided with two conductor fixing grooves 11 for setting the inductance conductor 3, and the two The inductance conductors 3 are respectively embedded in the two conductor fixing grooves 11, and the connecting pins on the two inductance conductors 3 are bent and attached to the circumferential side of the inductance magne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com