Preparation method of TCC group mode filtering electric connector and TCC group mode filtering electric connector

A technology for electrical connectors and mode filtering, which is applied in the direction of connecting parts to protect grounding/shielding devices, connections, parts of connection devices, etc. It can solve problems such as low corrosion resistance, high production costs, and multi-product quality, and achieve anti-corrosion High mechanical vibration intensity, strong anti-static ability, and the effect of ensuring production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

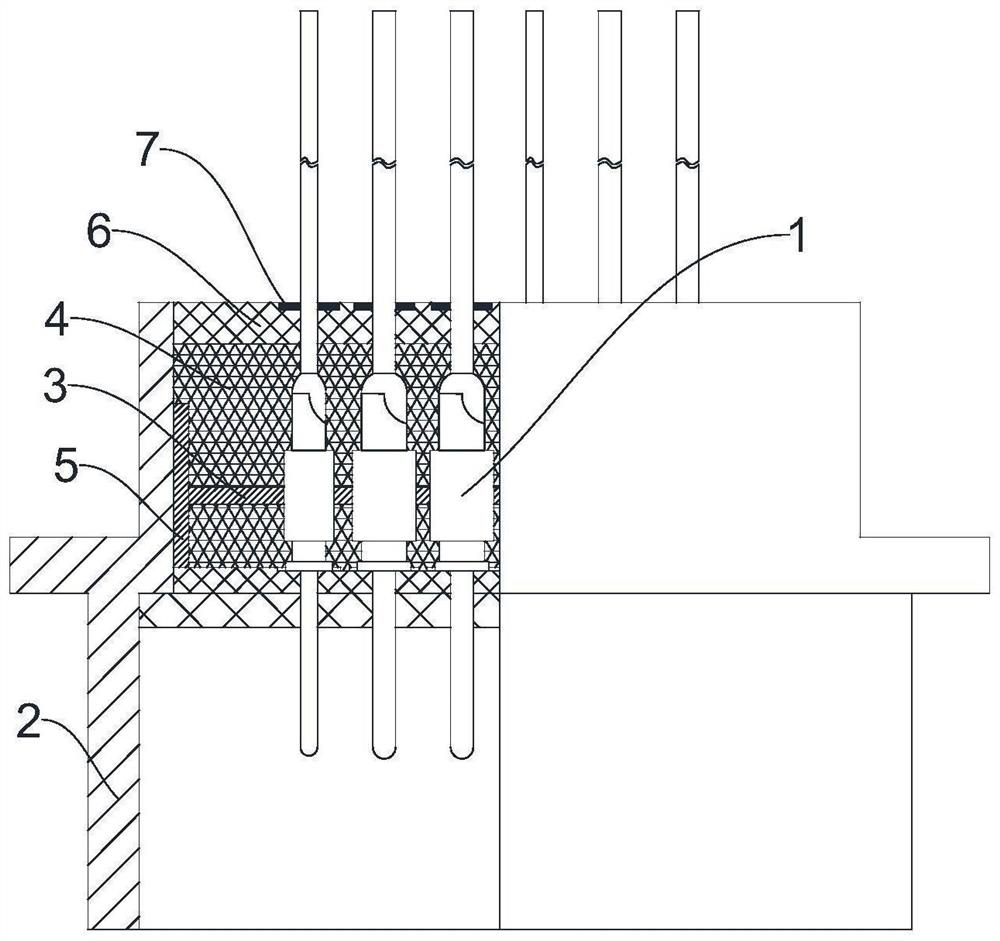

[0043] The preparation method of the TCC group mode filter electrical connector comprises the following steps:

[0044] a. Prepare the monolithic ceramic tube, metal contact body and shell required for production, and test the electrical performance index of the monolithic ceramic tube, the size of the metal contact body and the surface coating (check whether the coating is the corresponding required thickness, and The coating is a precious metal), which is tested by physical and chemical methods;

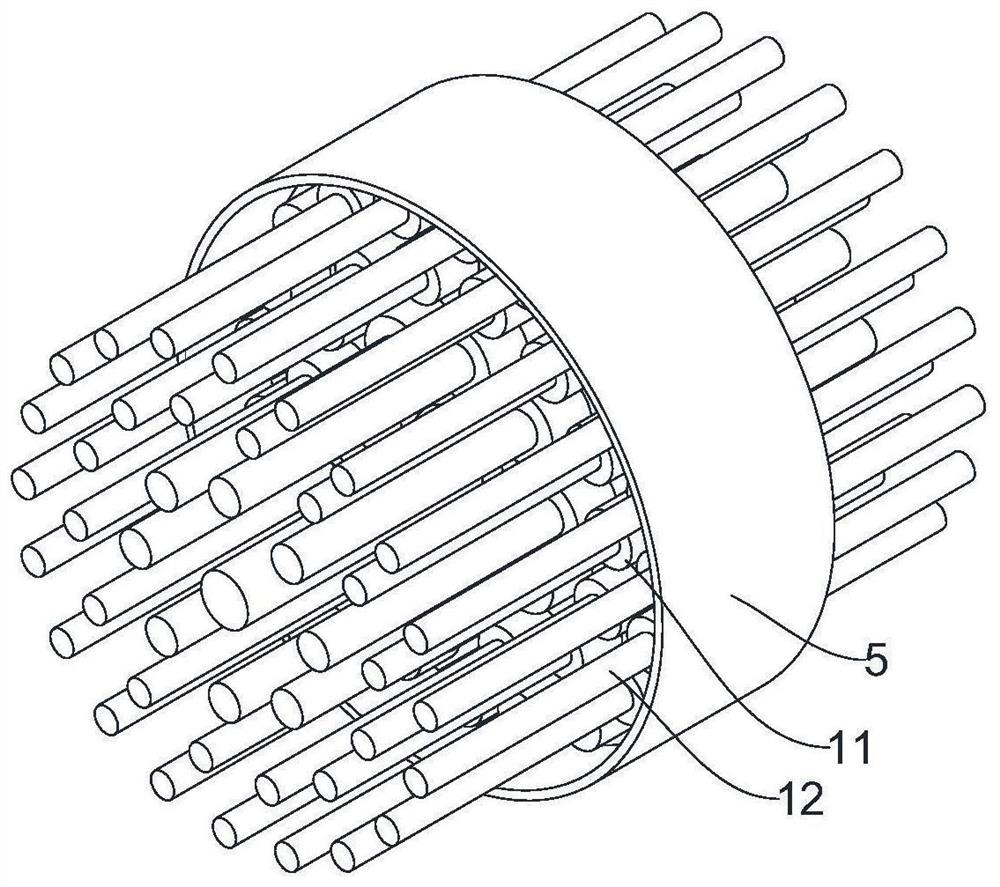

[0045] b. passing a metal contact body through a monolithic ceramic tube and connecting the outer surface of the metal contact body with the inner surface of the monolithic ceramic tube by welding to obtain an independent discrete assembly;

[0046] c. Check the welding index and filter electrical performance index of the discrete assembly obtained in b, inspect the TCC pipe body and the through-metal contact body for virtual welding and missing welding with a visual instrument, an...

Embodiment 2

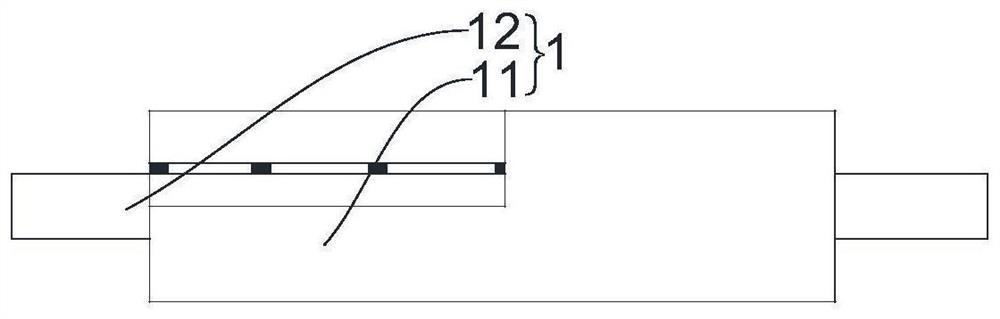

[0057] Both the grounding plate and the shell are Y-shaped, and the grounding plate corresponds to the model of the shell. The metal contact body is selected from high-frequency discrete assemblies; the solidified layer of the encapsulation material and the air contact surface are provided with a plastic insulating plate, which prevents leakage and assists the electrical connector to better realize the filtering function. The surface of the plastic insulating sleeve at the cable outlet end of the metal contact body is provided with a pattern identification sheet, which is convenient for distinguishing the corresponding functions of each discrete assembly and the connection with the corresponding cable. The center-to-center distance between the metal contacts is greater than or equal to 0.635. Under the condition of center spacing ≥ 2.54㎜, AC and DC mixed integration can be realized; under the condition of center spacing < 1.27㎜, C-type filter circuit can be used; under the con...

Embodiment 3

[0059] Both the grounding plate and the shell are Y-shaped, and the grounding plate corresponds to the model of the shell. The metal contact body is selected from the combination of the low-frequency discrete assembly and the high-frequency discrete assembly; the solidified layer of the encapsulation material and the air contact surface are provided with a plastic insulating plate, which prevents leakage and assists electrical connection The device can better realize the filtering function. The surface of the plastic insulating sleeve at the cable lead-out end of the metal contact body is provided with a pattern identification sheet, which is convenient for distinguishing the corresponding functions of each discrete assembly and the connection with the corresponding cable. The center-to-center distance between the metal contacts is greater than or equal to 0.635. Under the condition of center distance ≥ 2.54㎜, AC and DC mixed integration can be realized; under the condition o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com