Circuit board etching simulation method

A simulation method and circuit board technology, applied in printed circuits, printed circuit manufacturing, computer design circuits, etc., can solve problems such as insufficient yield rate, and achieve the effect of improving yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to explain in detail the technical content, structural features, achieved goals and effects of the technical solution, the following will be described in detail in conjunction with specific embodiments and accompanying drawings.

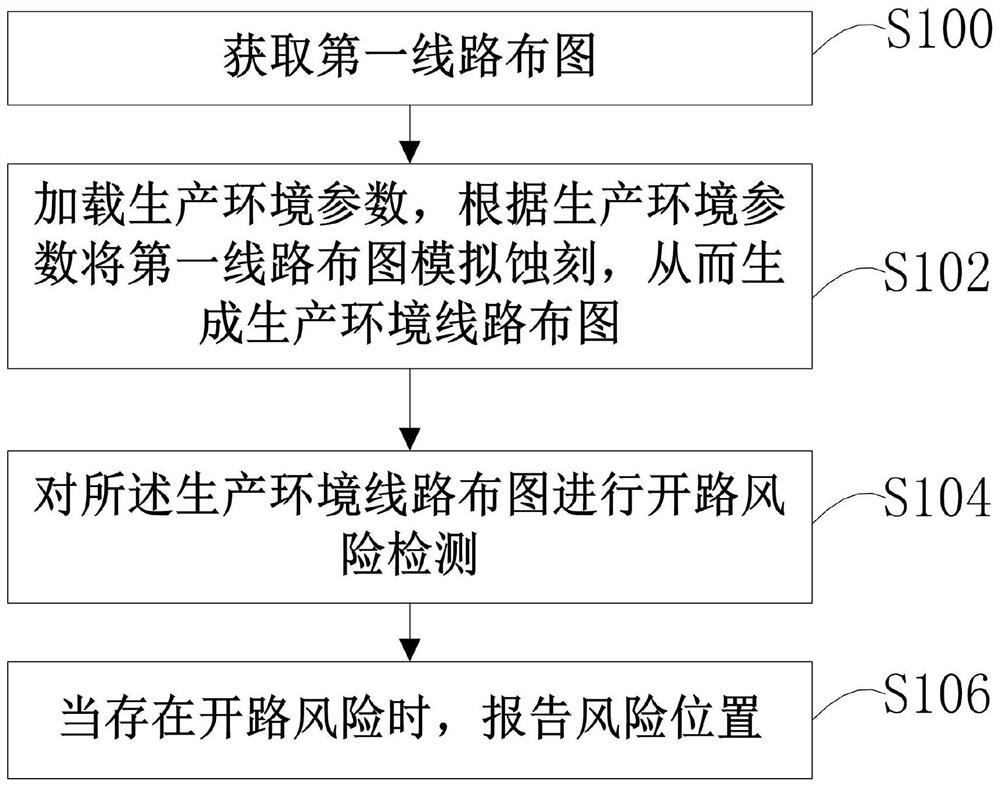

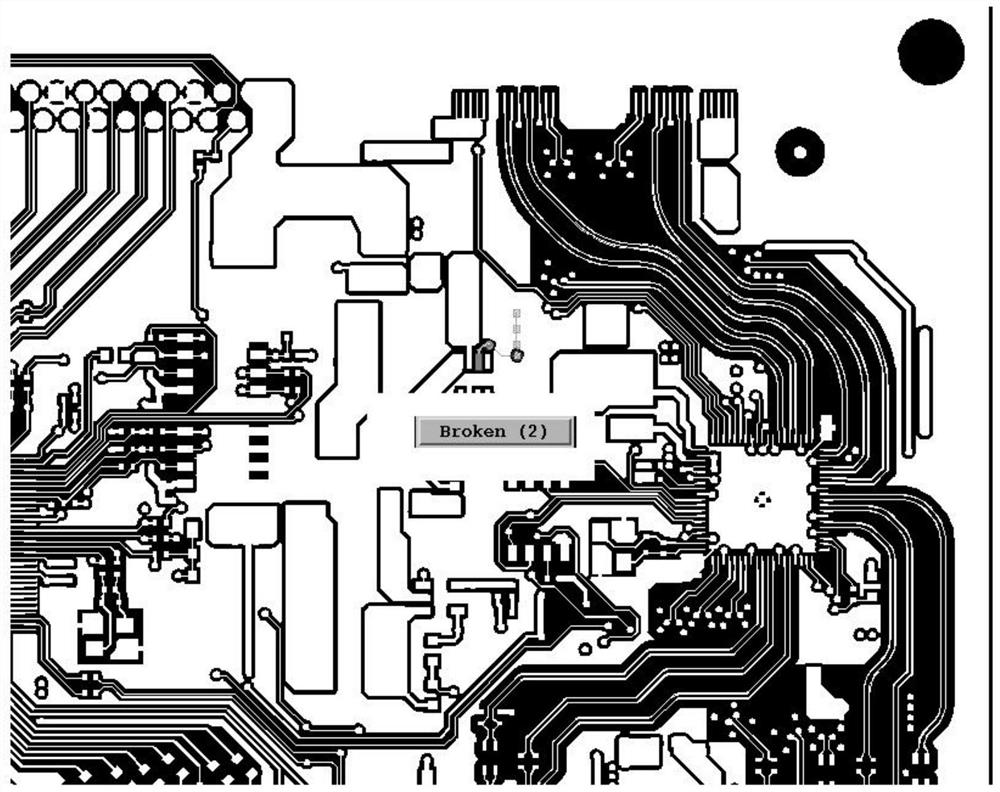

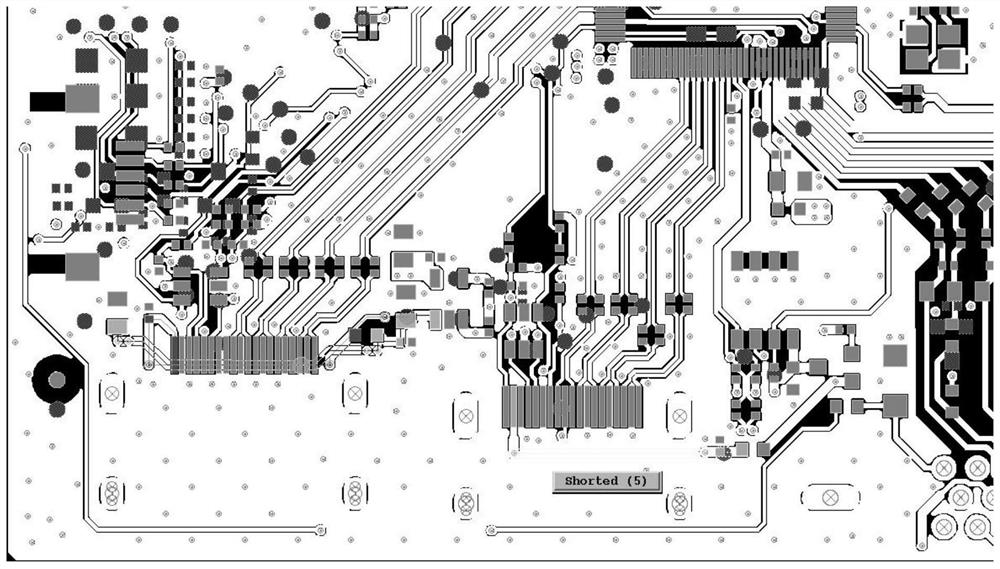

[0014] see figure 1 , a circuit board etching simulation method in this embodiment, comprising the following steps, S100 obtains a first circuit layout, the first circuit layout may be a pre-designed circuit design draft, including parameters such as layout line width, circuit The PCB plate based on the design draft will be over-etched in some cases according to the actual situation during production and processing, resulting in the problem that the quality of some products does not meet the standard. In order to give an alarm to this situation, we carry out the following steps, S102 loads the production environment parameters, simulates etching the first circuit layout according to the production environment parameters, thereby gener...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com