Preparation method of grinding paste tea

A technology of tea buds and bud heads, which is applied in the field of preparation of cream tea, which can solve problems such as poor taste and preservation, lack of preparation schemes, and cumbersome preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

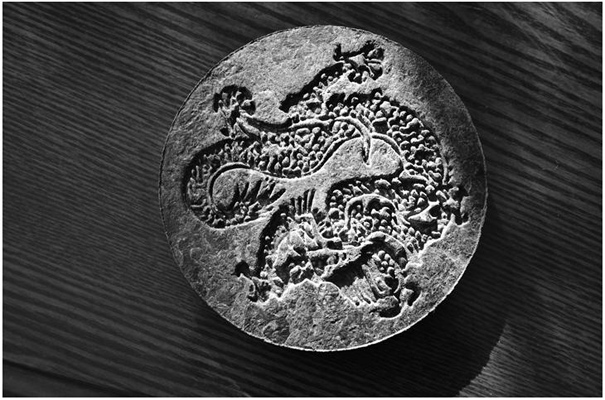

Image

Examples

Embodiment 1

[0024] A preparation method of cream tea, comprising the following steps:

[0025] (1) Picking: It is carried out in the morning when the temperature is low, usually around 25°C. The main picking is dew green. The picking standard is the young buds, which are then soaked in the spring water carried to prevent the buds from turning yellow. stop picking;

[0026] (2) Cleaning: After the tea buds are harvested, put them into ice-cold spring water for cleaning. The action is gentle, and excessive force should not be used to cause mechanical damage;

[0027] (3) Picking buds: remove sundries, stalk leaves and some hard skins on the outside of the bud heads to keep the bud heads tender and uniform;

[0028] (4) Green drying: spread evenly on the bamboo sieve for indoor cooling, so that the water on the surface of the tea buds evaporates, and the drying is controlled naturally. The cooling time is 2-3 hours, and the water loss rate of the buds is as high as 15%.

[0029] (5) Steam ...

Embodiment 2

[0036] A preparation method of cream tea, comprising the following steps:

[0037] (1) Picking: It is carried out in the morning when the temperature is low, usually around 25°C. The main picking is dew green. The picking standard is the young buds, which are then soaked in the spring water carried to prevent the buds from turning yellow. stop picking;

[0038] (2) Cleaning: After the tea buds are harvested, put them into ice-cold spring water for cleaning. The action is gentle, and excessive force should not be used to cause mechanical damage;

[0039] (3) Picking buds: remove sundries, stalk leaves and some hard skins on the outside of the bud heads to keep the bud heads tender and uniform;

[0040] (4) Green drying: spread evenly on the bamboo sieve for indoor cooling, so that the water on the surface of the tea buds evaporates, and the drying is controlled naturally. The cooling time is 2-3 hours, and the water loss rate of the buds is as high as 15%.

[0041] (5) Steam ...

Embodiment 3

[0048]A preparation method of cream tea, comprising the following steps:

[0049] (1) Picking: It is carried out in the morning when the temperature is low, usually around 25°C. The main picking is dew green. The picking standard is the young buds, which are then soaked in the spring water carried to prevent the buds from turning yellow. stop picking;

[0050] (2) Cleaning: After the tea buds are harvested, put them into ice-cold spring water for cleaning. The action is gentle, and excessive force should not be used to cause mechanical damage;

[0051] (3) Picking buds: remove sundries, stalk leaves and some hard skins on the outside of the bud heads to keep the bud heads tender and uniform;

[0052] (4) Green drying: spread evenly on the bamboo sieve for indoor cooling, so that the water on the surface of the tea buds evaporates, and the drying is controlled naturally. The cooling time is 2-3 hours, and the water loss rate of the buds is as high as 15%.

[0053] (5) Green s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com