Production process of highly self-solidifying high-fat yogurt

A production process and high-fat technology, applied in milk preparations, dairy products, applications, etc., can solve problems such as complex and cumbersome process steps, insufficient smooth and delicate taste, and insufficient milk flavor, achieving broad market value and refreshing taste The effect of smoothness, high viscosity and thick feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

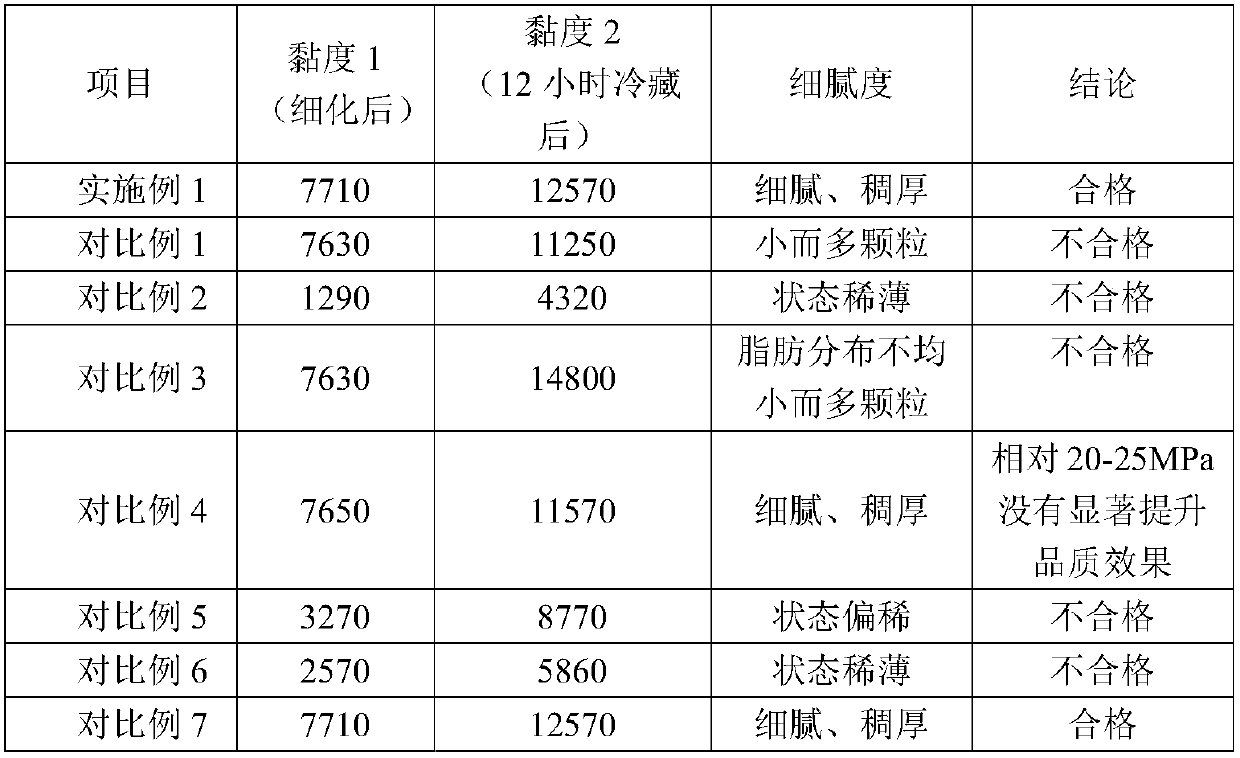

Examples

Embodiment 1

[0021] (1) Flash evaporation: Fresh milk is cleaned and flashed to obtain flash concentrated milk. The flash evaporation process parameters are: the flow rate of flash concentrated milk is 5000T / h, the flash evaporation temperature is 50°C, and the vacuum degree is 0.05Pa.

[0022] (2) Ingredients: heat up the flash concentrated milk to 50±2°C, add starch and white sugar and stir for 8 minutes, then add cream, constant volume and stir for 8 minutes to obtain the fermented material, based on the total mass of the fermented material, add starch The amount is 1%, the added amount of white granulated sugar is 7%, the added amount of cream is 10%, and the balance is flash evaporated condensed milk, wherein the fat content range of cream is 50%.

[0023] (3) Homogenization and sterilization: Homogenize the fermented material at 45°C and 20MPa pressure, then sterilize at 93°C for 300s, cool to 30±4°C and transport to the fermenter.

[0024] (4) Fermentation: After inoculating the fer...

Embodiment 2

[0047] (1) Flash evaporation: Fresh milk is cleaned and flashed to obtain flash concentrated milk. The flash evaporation process parameters are: the flow rate of flash concentrated milk is 5000T / h, the flash evaporation temperature is 55°C, and the vacuum degree is 0.1Pa.

[0048] (2) Ingredients: heat up the flash concentrated milk to 50±2°C, add starch and white sugar and stir for 9 minutes, then add cream, constant volume and stir for 9 minutes to obtain the fermented material, based on the total mass of the fermented material, add starch The amount is 1.5%, the added amount of white granulated sugar is 8%, the added amount of cream is 11%, and the balance is flash evaporated condensed milk, wherein the fat content of cream is 60%.

[0049] (3) Homogenization and sterilization: After homogenizing the fermentation material at a temperature of 52°C and a pressure of 24MPa, it was sterilized at 94°C for 300s, cooled to 30±4°C and then transported to the fermenter.

[0050] (4)...

Embodiment 3

[0054] (1) Flash evaporation: Fresh milk is cleaned and flashed to obtain flash concentrated milk. The flash evaporation process parameters are: the flow rate of flash concentrated milk is 5000T / h, the flash temperature is 60°C, and the vacuum degree is 0.15Pa.

[0055] (2) Ingredients: heat up the flash condensed milk to 50±2°C, add starch and white sugar and stir for 10 minutes, then add cream, constant volume and stir for 10 minutes to obtain the fermented material, based on the total mass of the fermented material, add starch The amount is 2%, the added amount of white granulated sugar is 10%, the added amount of cream is 12%, and the balance is flash evaporated condensed milk, wherein the fat content range of the cream is 70%.

[0056] (3) Homogenization and sterilization: Homogenize the fermented material at 75°C and 25MPa pressure, then sterilize at 97°C for 300s, cool to 30±4°C and transport to the fermenter.

[0057] (4) Fermentation: After inoculating the fermentatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com