Material-saving water-absorbing sanitary fabric as well as production device and use method thereof

A technology that saves materials and produces equipment. It can be used in applications, absorbent pads, textiles and papermaking. It can solve the problems of high cost, no surrounding layout, affecting air permeability and soft comfort, etc., to ensure regularity and avoid unnecessary Use, avoid the effect of rigid defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

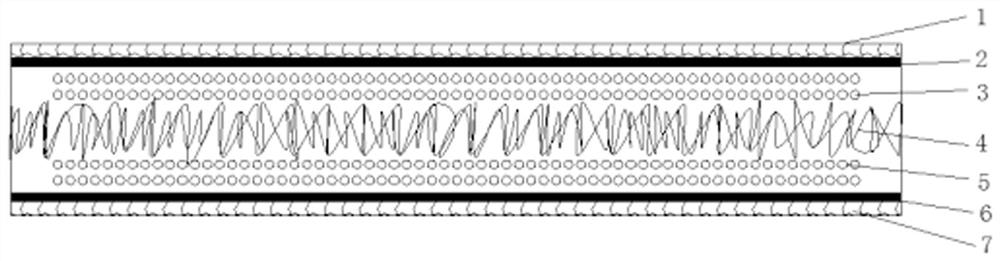

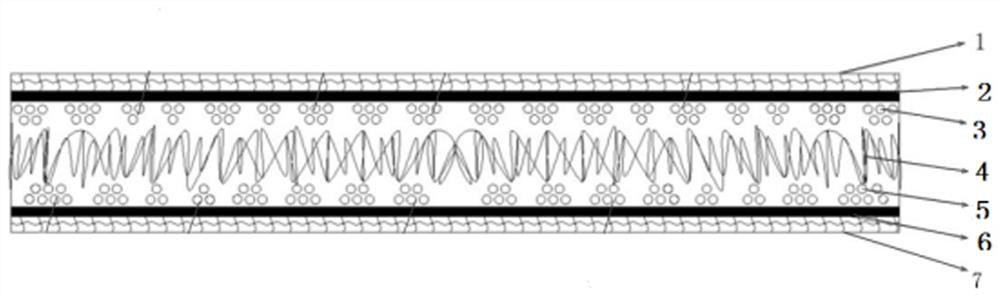

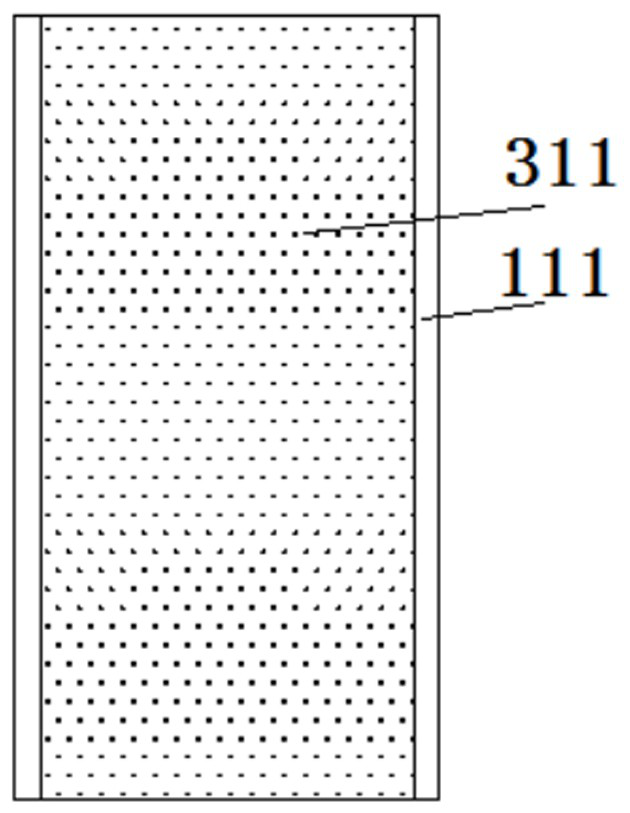

[0054] An absorbent hygienic fabric that saves material, the conventional fabric manufacturing process is to produce large rolls and then cut small rolls. Therefore, it is the quickest way to increase the non-SAP particle layer on both sides of the fabric, such as image 3 As shown, 311 is the area where SAP particles are distributed, and 111 is the area where SAP particles are not distributed. There is no SAP particle layer on the left and right sides, and SAP particles are distributed or spaced in the middle area according to the product design. Both the first layer and the second layer on the left and right sides are coated with viscous glue, so that the first layer and the second layer are compounded through the viscous glue, which will effectively prevent SAP particles from leaking from both sides after compounding.

Embodiment 2

[0056] Such as Figure 4 As shown, 312 is the area where SAP particles are distributed, and 112 is the area where SAP particles are not distributed. There is no SAP particle layer at the front and rear positions, and SAP particles are distributed or spaced in the middle area according to the product design. Both the first layer and the second layer on the front and rear sides are coated with viscous glue, so that the first layer and the second layer are compounded by viscous glue, which will effectively prevent SAP particles from leaking from the front and rear sides after compounding. This design is convenient for connection and alignment during the production of sanitary products.

Embodiment 3

[0058] Such as Figure 5 As shown, 313 is the area where SAP particles are distributed, and 113 is the area where SAP particles are not distributed. There is no SAP particle layer at the front and rear positions and on the left and right sides, and SAP particles are distributed or spaced according to the product design in the middle area. In the area without SAP particle layer around, the first layer and the second layer are compounded by viscous glue, which will effectively prevent SAP particles from leaking from the front and rear sides after compounding. This structural design combines the advantages of Embodiment 1 and Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com