Oil point equipment and spraying method for plastic products

A technology of spotting oil and equipment, which is applied in the direction of chemical instruments and methods, coatings, and devices for coating liquid on the surface. Yield and efficiency are difficult to be guaranteed and other issues, to achieve the effect of mass production, avoiding too much or too little oil filling, and ensuring yield and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to describe the technical content and structural features of the present invention in detail, further description will be given below in conjunction with the implementation and accompanying drawings.

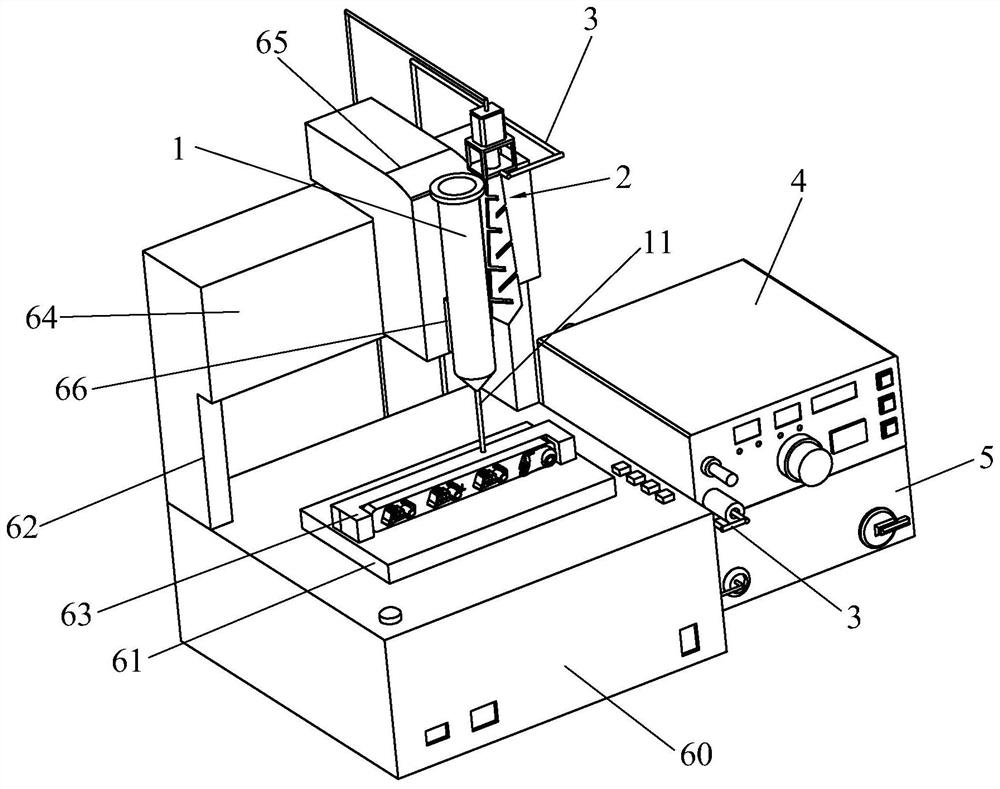

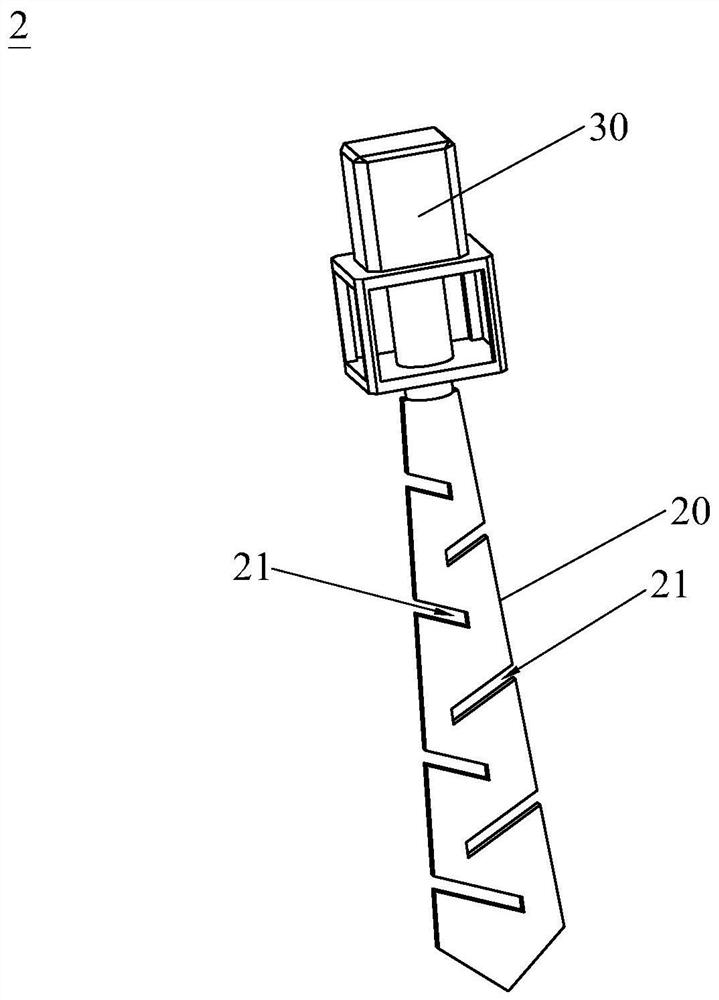

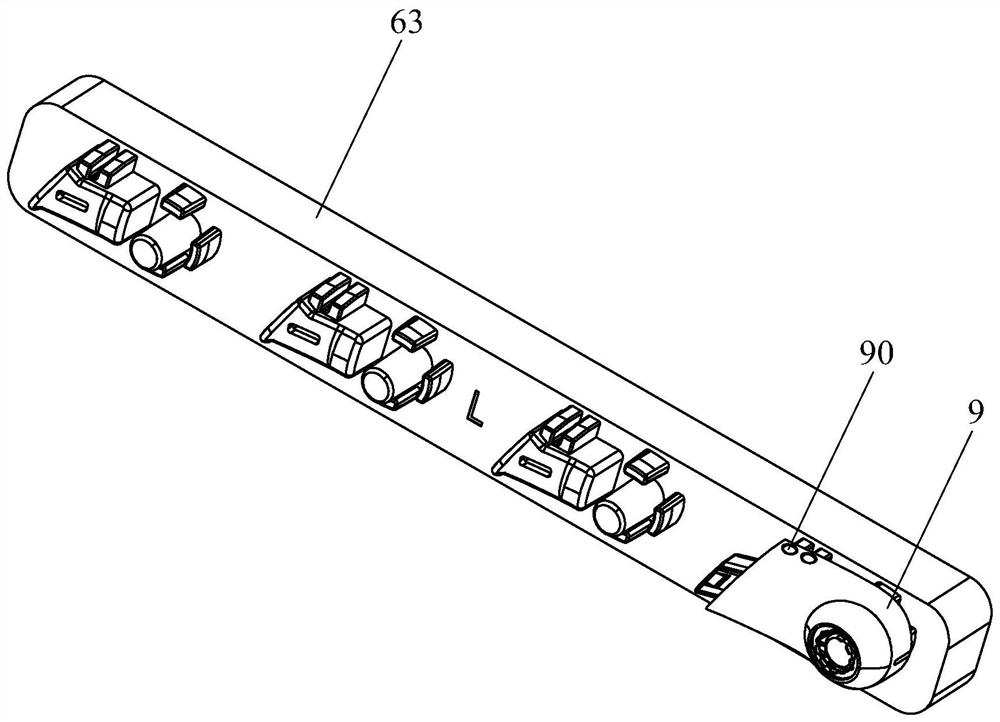

[0028] see Figure 1 to Figure 3 , the invention discloses a kind of oil point equipment, including a syringe 1, an agitator 2, an air pipe 3, an air pressure supply device 4 and a control device 5, the agitator 2 includes an agitating member 20 extending into the syringe 1 and connected to the agitating The stirring drive mechanism 30 at the upper end of the part 20, one end of the air pipe 3 is connected to the air pressure supply device 4, and the other end of the air pipe 3 is set corresponding to the syringe 1, and the air pressure supply device 4 compresses the air in the syringe 1 through the air pipe 3 to control the point oil, The control device 5 controls the stirring of the stirring drive mechanism 30 . In the present invention, the air pipe 3 may or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com