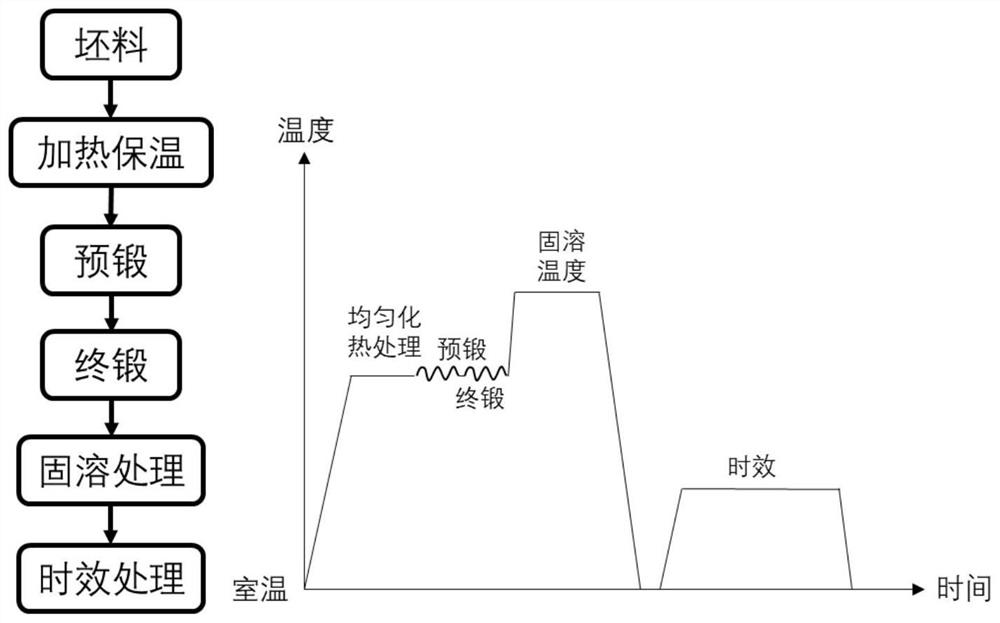

Aluminum alloy part forging process

A technology of aluminum alloy parts and aluminum alloy, which is applied in the field of thermal processing of materials, can solve the problems of high energy consumption for multiple heating, long production cycle, etc., and achieve the effect of reducing the time of artificial aging, reducing the production cycle, and rapid hot forming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

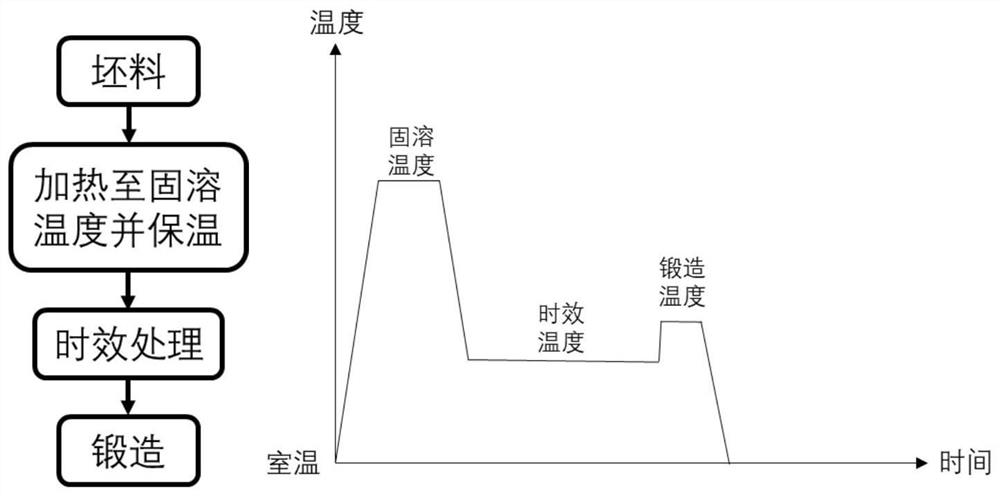

[0028] A kind of forging technology of aluminum alloy part, for the simple part that only needs to carry out die forging once, comprises following steps (as figure 2 shown):

[0029] S1, heating the aluminum alloy billet to the solution temperature in the heating equipment (for solution treatment), the heating and holding time is determined according to the wall thickness of the aluminum alloy billet, and the heat preservation is 20min according to the thickness of each aluminum alloy billet of 1mm; The aluminum alloy is 6000 series aluminum alloy; the heating time and holding time are controlled within 90 minutes;

[0030] S2. Underaging heat treatment is performed on the aluminum alloy blank, the temperature is controlled at 100-150°C, and the time is controlled at 2-8h;

[0031] S3. Heat the aluminum alloy billet after underaging treatment at 200-250°C for 5-10min, and preheat the forging die to 200°C;

[0032] S4. Performing isothermal die forging at 100-300° C. to fina...

Embodiment 2

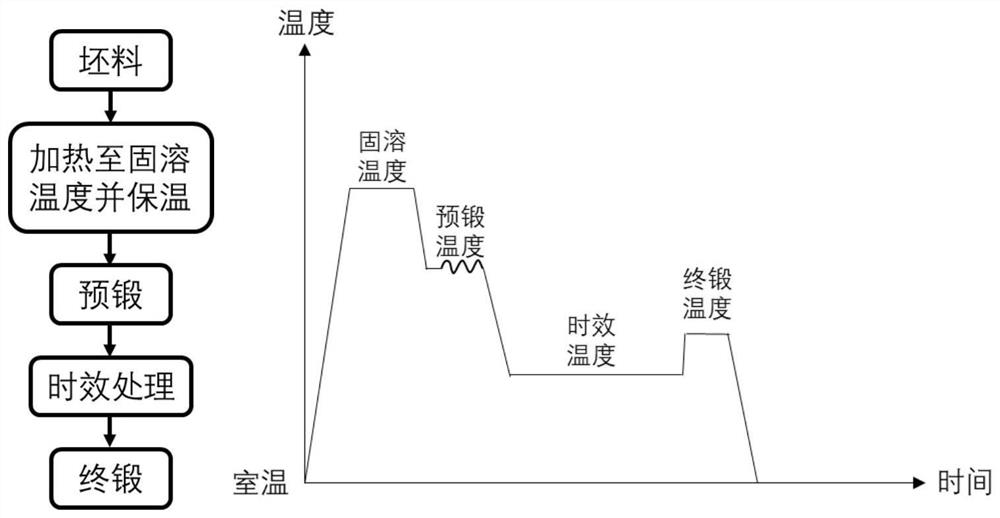

[0037] A kind of forging process of aluminum alloy parts, for the complicated piece that needs to carry out multiple die forgings, comprises the following steps (such as image 3 shown):

[0038] S1. Perform solid solution treatment on the aluminum alloy billet in the heating equipment. The heating and holding time is determined according to the wall thickness of the aluminum alloy billet, and is heated and held for 20 minutes according to the wall thickness of the aluminum alloy billet of 1mm; the aluminum alloy is a 6000 series aluminum alloy ;

[0039] S2. Heating the mold to the forging temperature, cooling the aluminum alloy billet to a pre-forging temperature of 450° C., and pre-forging the aluminum alloy billet after solution treatment;

[0040] S3. Perform underaging heat treatment on the pre-forged parts, the temperature is 100-150°C, and the time is 2-8h;

[0041] S4. Keep the parts after underaging treatment at 200-250°C for 5-10 minutes, and preheat the final for...

Embodiment 3

[0049] A forging process of an aluminum alloy part, comprising the following steps: when the blank material of the aluminum alloy is 6082 aluminum alloy, the specific forging process and parameters are as follows:

[0050] S1. Perform solid solution treatment on the aluminum alloy billet in the heating equipment, the temperature is 535°C, the heating and holding time is determined according to the size of the billet, and the heating and holding time is 20 minutes per wall thickness of 1 mm;

[0051] S2. Pre-forging the aluminum alloy blank after solution treatment at 450° C.;

[0052] S3. Perform underaging heat treatment on the pre-forged parts, the temperature is 120±5°C, and the time is 4-6h;

[0053] S4. The parts after under-aging treatment are kept at 200±5°C for 5-10 minutes, and the final forging die is preheated to 200°C;

[0054] S5. Performing isothermal die forging at 100-300° C. for final forging of the parts after underaging treatment;

[0055] S6. After the fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com