A heat treatment process for improving the strength of nickel-based superalloy at room temperature

A nickel-based superalloy, room temperature technology, applied in the field of nickel-based superalloy heat treatment, can solve the problems of cumbersome process, long aging time of heat treatment process, etc., achieve good mutual matching, improve the room temperature strength of the alloy, and increase the effect of γ' phase content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

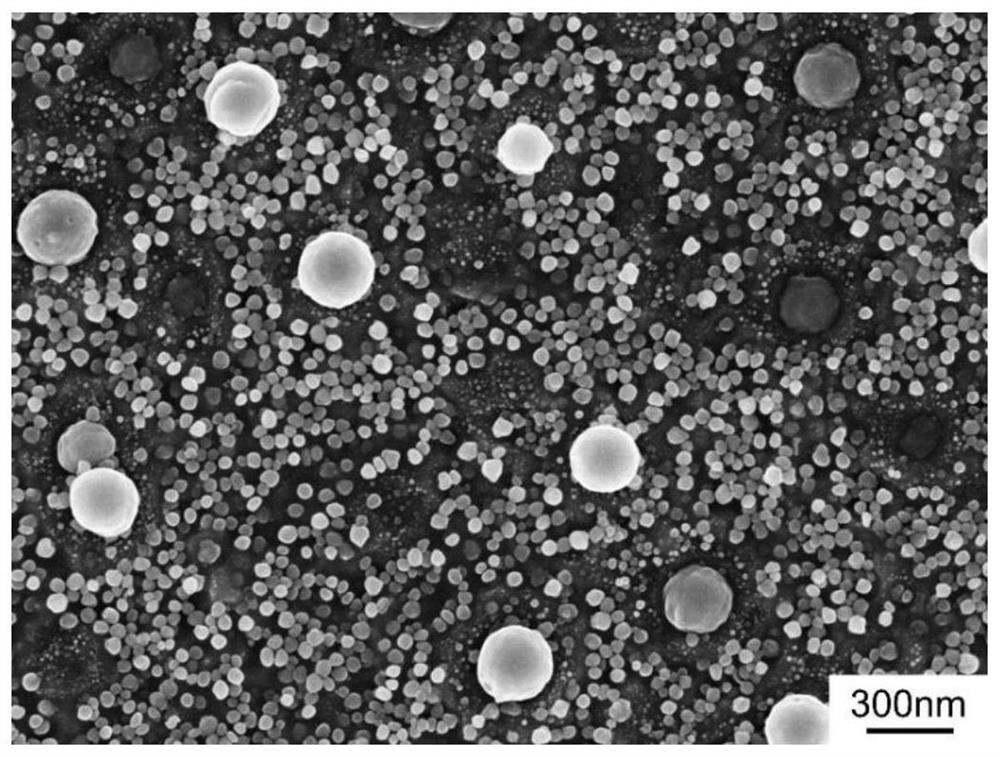

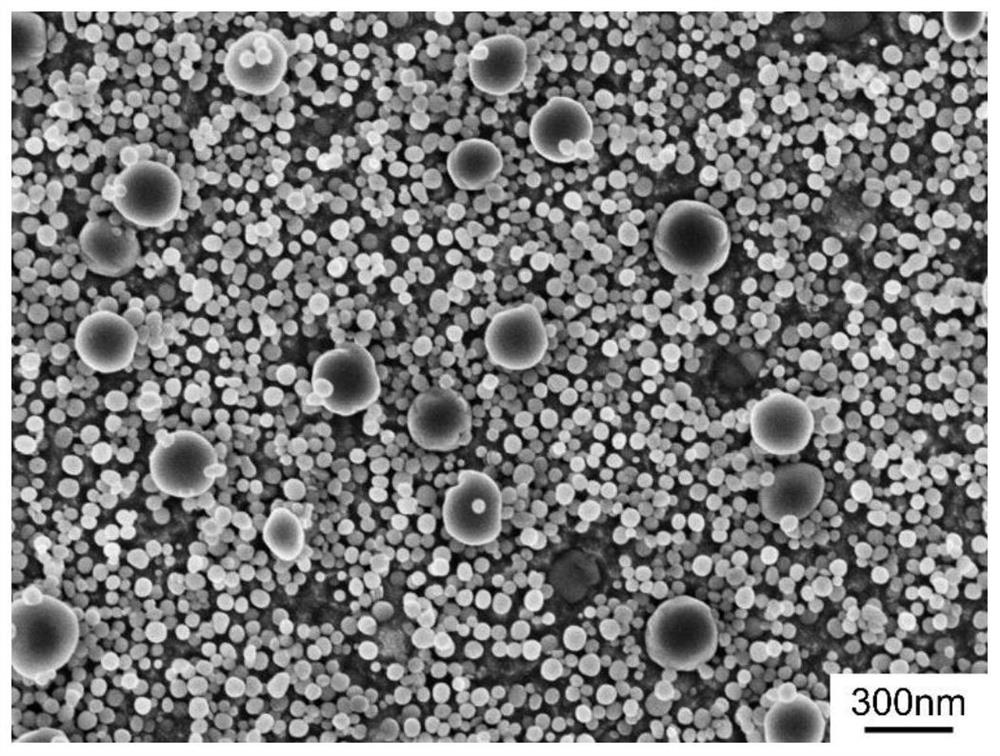

Image

Examples

specific Embodiment 1

[0025] Step 1: The GH4738 alloy forging is heated at a rate of 15 °C / min to 1030 °C for solution treatment for 30 minutes, and after taking it out, it is cooled to room temperature at a rate of 400-600 °C / min by blowing strong wind;

[0026] Step 2: The GH4738 alloy forging is heated to 760°C at a rate of 20°C / min for aging treatment for 14 hours, and then cooled to room temperature with the furnace.

specific Embodiment 2

[0028] Step 1: The GH4738 alloy forging is heated at a rate of 20 °C / min to 1020 °C for solution treatment for 50 min, and after taking it out, it is cooled to room temperature at a rate of 400-600 °C / min by blowing strong wind;

[0029] Step 2: The GH4738 alloy forging was aged at a rate of 25°C / min to 750°C for 16 hours, and then cooled to room temperature with the furnace.

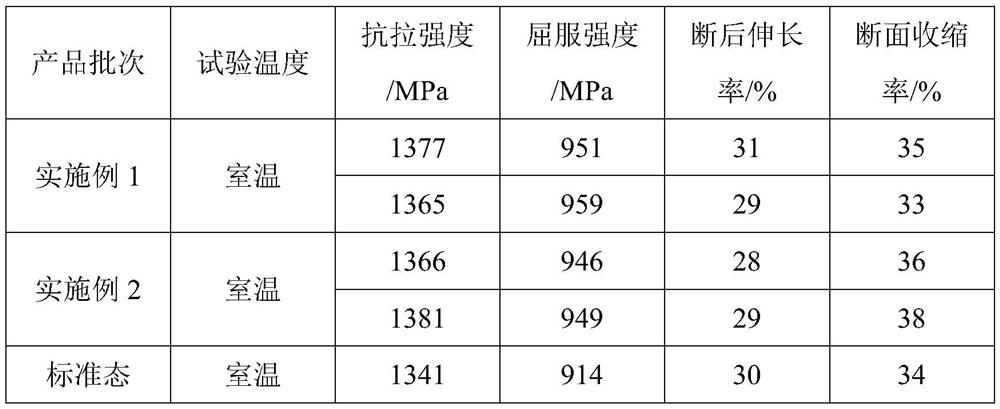

[0030] The test results of the mechanical properties of several groups of furnace samples show that the strength value of the GH4738 alloy at room temperature has been significantly improved after being treated by the heat treatment process of the present invention. 40, 45MPa.

[0031] The results of the mechanical properties tested with the furnace samples are shown in Table 2;

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com