Steel strip for automobile hollow stabilizer bar and production method thereof

A production method and technology for stabilizer bars, applied in the field of metallurgy, can solve the problems of unsatisfactory use effect, poor anti-fatigue performance, low service life, etc., so as to ensure the fatigue performance of stabilizer bars, high tensile strength, and improve the forming performance of steel coils Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

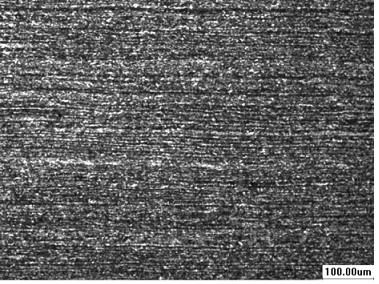

Embodiment 1

[0038] The thickness of the finished hot-rolled steel strip for the hollow stabilizer bar in this embodiment is 4.0 mm, and its chemical composition and mass percentage are shown in Table 1.

[0039] The production method of the hot-rolled steel strip for the hollow stabilizer bar of this embodiment includes converter smelting, LF refining, continuous casting, heating, rough rolling, finish rolling, cooling and coiling processes, and the specific process steps are as follows:

[0040] (1) Continuous casting process: control the composition segregation by stabilizing the casting speed, the casting speed is 1.20m / min, and the steel billet with a thickness of 180mm and a width of 1280mm is obtained by continuous casting. The chemical composition and mass percentage of the continuous casting billet are shown in Table 1;

[0041] (2) Heating process: heating by a walking heating furnace, the total residence time in the heating furnace is 160min, the heating temperature in the soakin...

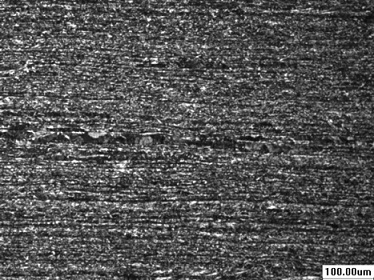

Embodiment 2

[0048] The finished product thickness of the hot-rolled steel strip for the hollow stabilizer bar in this embodiment is 5.0mm, and its chemical composition and mass percentage are shown in Table 1.

[0049] The production method of the hot-rolled steel strip for the hollow stabilizer bar of this embodiment includes converter smelting, LF refining, continuous casting, heating, rough rolling, finish rolling, cooling and coiling processes, and the specific process steps are as follows:

[0050](1) Continuous casting process: control component segregation through stable casting speed, casting speed 1.30m / min, continuous casting to obtain a billet with a thickness of 200mm and a width of 1250mm, the chemical composition and mass percentage of the continuous casting billet are shown in Table 1;

[0051] (2) Heating process: heating by a walking heating furnace, the total residence time in the heating furnace is 208 minutes, the heating temperature in the soaking section of the heatin...

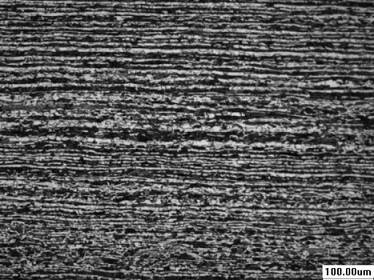

Embodiment 3

[0058] The finished product thickness of the hot-rolled steel strip for the hollow stabilizer bar in this embodiment is 5.0mm, and its chemical composition and mass percentage are shown in Table 1.

[0059] The production method of the finished hot-rolled steel strip for the hollow stabilizer bar of this embodiment includes converter smelting, LF refining, continuous casting, heating, rough rolling, finish rolling, cooling and coiling processes, and the specific process steps are as follows:

[0060] (1) Continuous casting process: control component segregation through stable casting speed, the casting speed is 1.30m / min, and continuous casting produces a billet with a thickness of 210mm and a width of 1300mm. The chemical composition and mass percentage of the continuous casting billet are shown in Table 1;

[0061] (2) Heating process: heating by a walking heating furnace, the total residence time in the heating furnace is 210min, the heating temperature in the soaking sectio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com