Equal-angle drilling device

A drilling device and isometric technology, applied in positioning devices, clamping devices, boring/drilling and other directions, can solve the problems of many steps, time-consuming and laborious, inaccurate and other problems, achieve stable and reliable structure, improve work efficiency, The effect of a high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

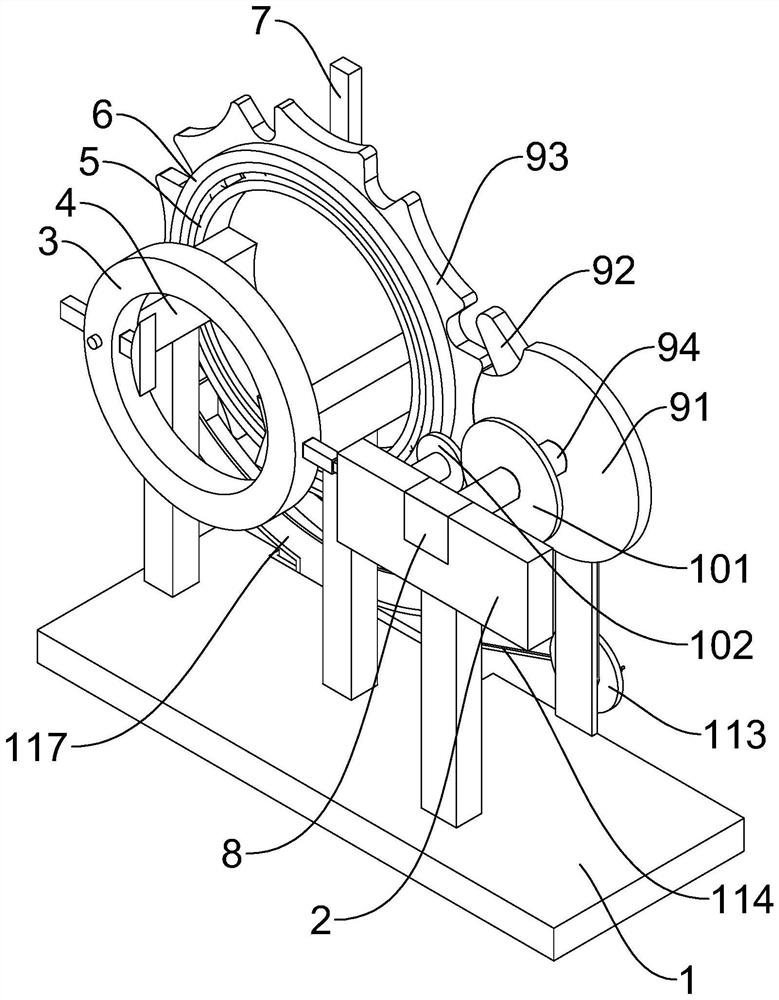

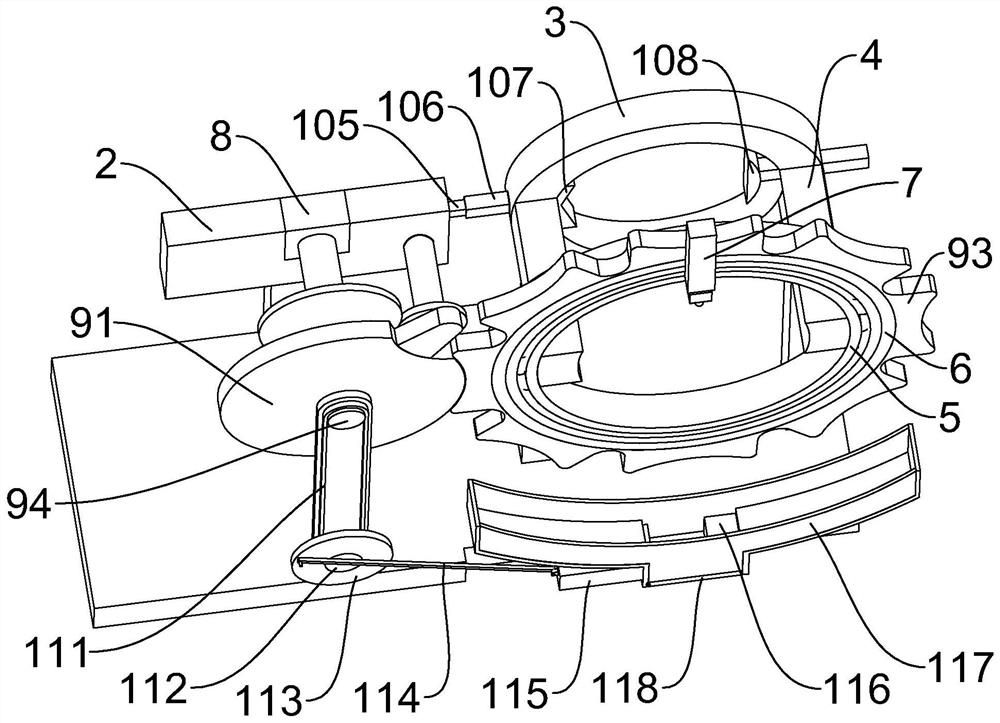

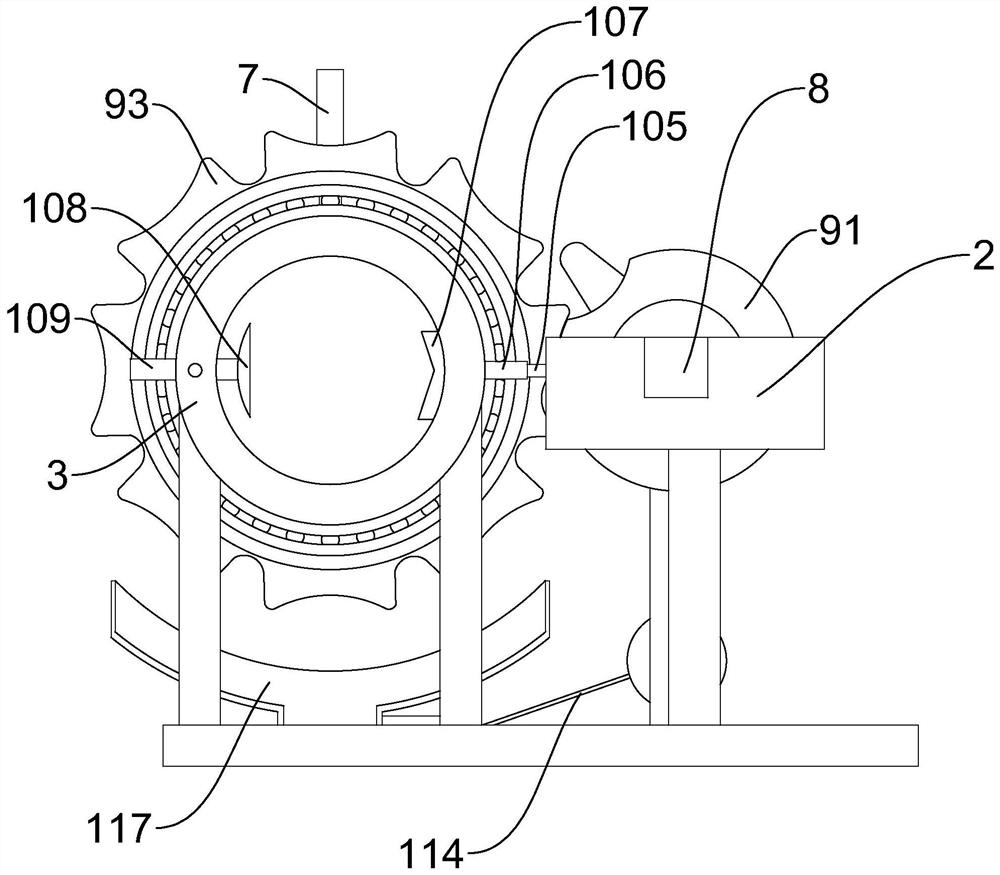

[0025] like Figure 1 to Figure 12 As shown, an equiangular drilling device includes a base 1, the left and right sides above the base 1 are respectively provided with a connecting block 4 and a fixed block 2 through brackets, and the front and rear ends of the connecting block 4 are respectively provided with a first ring 3 , bearing 5, the outer ring of bearing 5 is keyed with second annulus 6, the rear side of the second annulus 6 upper ends is provided with stepping air cylinder 7, is connected with drilling machine on the piston of stepping air cylinder 7, fixed block 2 A stepping motor 8 is provided inside, and the output shaft of the stepping motor 8 is connected with a rotating mechanism 9 for intermittently making the second annulus 6 rotate at the same angle. The clamping assembly 10 connected to the output shaft of the motor 8, the base 1 is provided with the collection assembly 11 matched with the rotating mechanism 9, the rotating mechanism 9 includes the first ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com