Eco-friendly polyester molding composition and method for manufacturing plastic board

A molding composition and plastic sheet technology, applied in the direction of coating, etc., can solve the problems of increasing manufacturing costs, not in line with economic benefits, etc., and achieve the effect of reducing the dissipation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

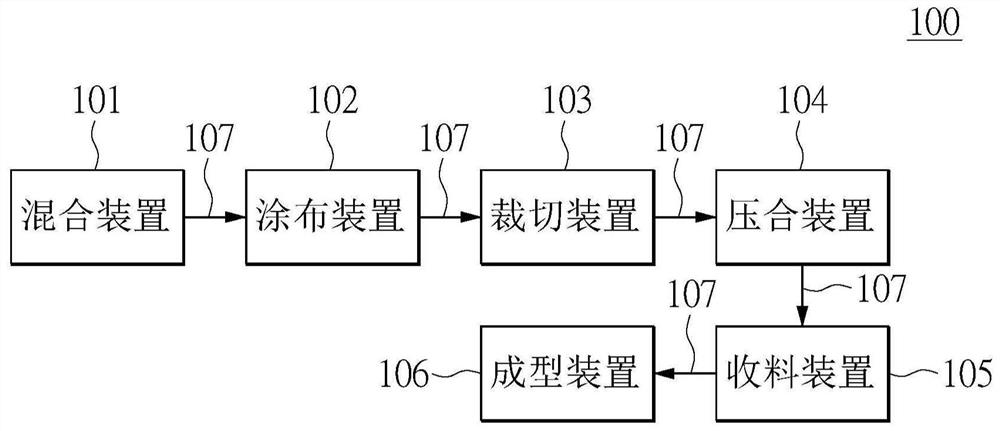

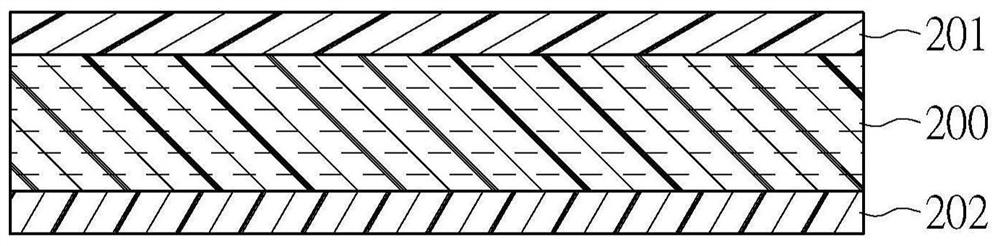

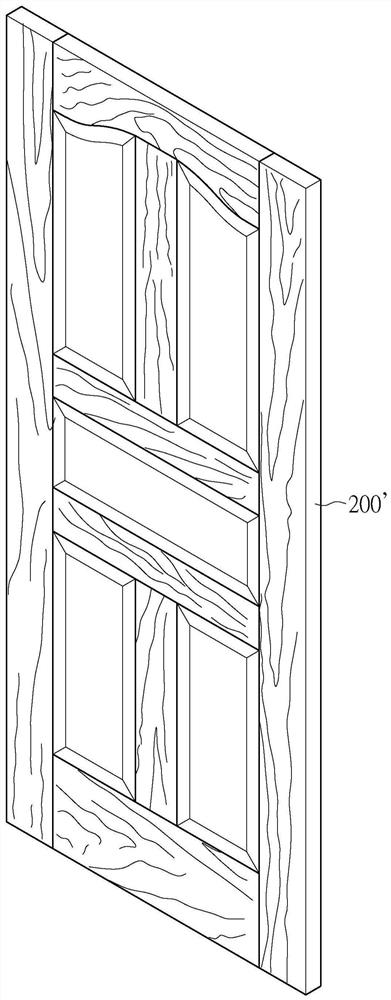

Method used

Image

Examples

experiment example 1

[0035] The environment-friendly polyester molding composition includes 60 parts by weight of unsaturated polyester resin, 150 parts by weight of calcium carbonate as filler, 60 parts by weight of glass fiber, 0.5 to 10 parts by weight of initiator and 60 parts by weight of additive. In the experimental example, the high-temperature initiator is selected from tertiary butyl peroxybenzoate, and the medium-low temperature initiator is selected from 1,1-bis(tert-butyl peroxide)-3,3,5-trimethylcyclohexane, The mass ratio is 2:1; the molding temperature is 135°C to 145°C. According to the ASTM D5116 standard method, and detected by gas chromatography mass spectrometry, the dissipation rate of styrene is 1320 μg / m 2 ×hr, the estimated average daily absorbed dose (Lifetime Average Daily Dose, LADD) of styrene is 700-800 μg / day. The additives can be selected from at least one of polymerization inhibitors, low shrinkage agents, tackifiers, release agents and colorants.

experiment example 2

[0037] The ingredients and dosage ratio of the environment-friendly polyester molding composition are the same as in Experimental Example 1, the difference is that the high-temperature initiator is tertiary butyl peroxybenzoate, and the medium-low temperature initiator is 1,1-bis(tert-butyl peroxybenzoate). oxide)-3,3,5-trimethylcyclohexane, the mass ratio is 2.5:1; the molding temperature is 135°C to 145°C. According to the ASTM D5116 standard method, and detected by gas chromatography mass spectrometry, the dissipation rate of styrene is 228 μg / m 2 ×hr, the estimated LADD of styrene is 134.1 μg / day.

experiment example 3

[0039] The ingredients and dosage ratio of the environment-friendly polyester molding composition are the same as in Experimental Example 1, the difference is that the high-temperature initiator is tertiary butyl peroxybenzoate, and the medium-low temperature initiator is 1,1-bis(tert-butyl peroxybenzoate). oxide)-3,3,5-trimethylcyclohexane, the mass ratio is 1.6:1; the molding temperature is 137°C to 145°C. According to the ASTM D5116 standard method, and detected by gas chromatography mass spectrometry, the dissipation rate of styrene is 30 μg / m 2 ×hr, the estimated LADD of styrene is 15-25 μg / day.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com