A kind of inorganic environment-friendly bone pulp modeling paint and preparation method thereof

An inorganic and environmentally friendly technology, applied in coating and other directions, can solve the problems of unsmooth gun discharge, serious mining of mineral resources, and high production costs, and achieve the effects of improving viscosity and thixotropy, rational utilization of resources, and reduction of production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

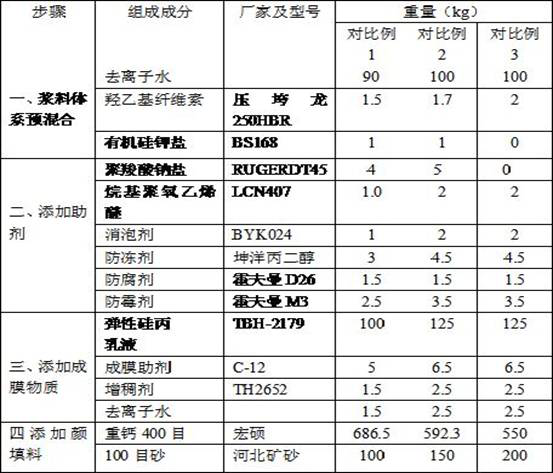

[0017] The components, weight and consumption of each component of Examples 1 to 3 and Comparative Examples 1 to 3 are shown in Tables 1 and 2.

[0018] Table I

[0019]

[0020] Table II

[0021]

Embodiment 1

[0022] Embodiment 1 This embodiment provides a method for making a new type of inorganic environmentally friendly bone paste modeling paint. The steps are as follows: Step 1: Add 150 kg of deionized water to a pre-dissolving tank, start stirring, and then slowly add Crude Dragon 250HBR under stirring 1kg of hydroxyethyl cellulose, then dispersed at 600 rpm for 10min, and then added 5kg of LOPON827 dispersion stabilizer at 600 rpm. Disperse for 5 minutes until the cellulose has no particles, no agglomeration, and a transparent gel. After completion, it will be used in step 2.

[0023] Step 2: Add 180kg of RS-837-1 organic-inorganic composite emulsion to the production tank under the stirring state of 600 rpm, and disperse for 5 minutes to a uniform state. After completion, it will be used in step 3.

[0024] Step 3: Adjust the speed of the disperser to 500 rpm in the completed step 2, slowly add 100kg of 60#~120# aeolian sand in this state, and adjust the speed to 800 rpm aft...

Embodiment 2

[0026] Example 2 Step 1: add 200kg of deionized water in the pre-dissolving tank, start stirring, then slowly add 2kg of hydroxyethyl cellulose of Cruzolone 250HBR under stirring, then disperse for 10min at 600 rev / min, then Add 4kg of LOPON827 dispersion stabilizer at 600 rpm. Disperse for 5 minutes until the cellulose has no particles, no agglomeration, and a transparent gel. After completion, it will be used in step 2.

[0027] Step 2: Add 150kg of RS-837-1 organic-inorganic composite emulsion to the production tank under the stirring state of 600 rpm, and disperse for 5 minutes to a uniform state. After completion, it will be used in step 3.

[0028] Step 3: Adjust the speed of the disperser to 500 rpm in the completed step 2, and slowly add 150kg of 60#~120# aeolian sand in this state. After the addition is completed, adjust the speed to 800 rpm and disperse for 15min to uniform state. Then add 491kg of 80#~120# soil bleaching quicksand. The speed is adjusted to 1000...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com