A kind of photocatalytic fresh-keeping paint and super fresh paper coated with the fresh-keeping paint

A photocatalytic and coating technology, which is applied in paper coatings, polyether coatings, antifouling/underwater coatings, etc., can solve the problems of not having fresh-keeping functions, and achieve the reduction of catalytic effects, inhibition of growth and reproduction, and high activity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

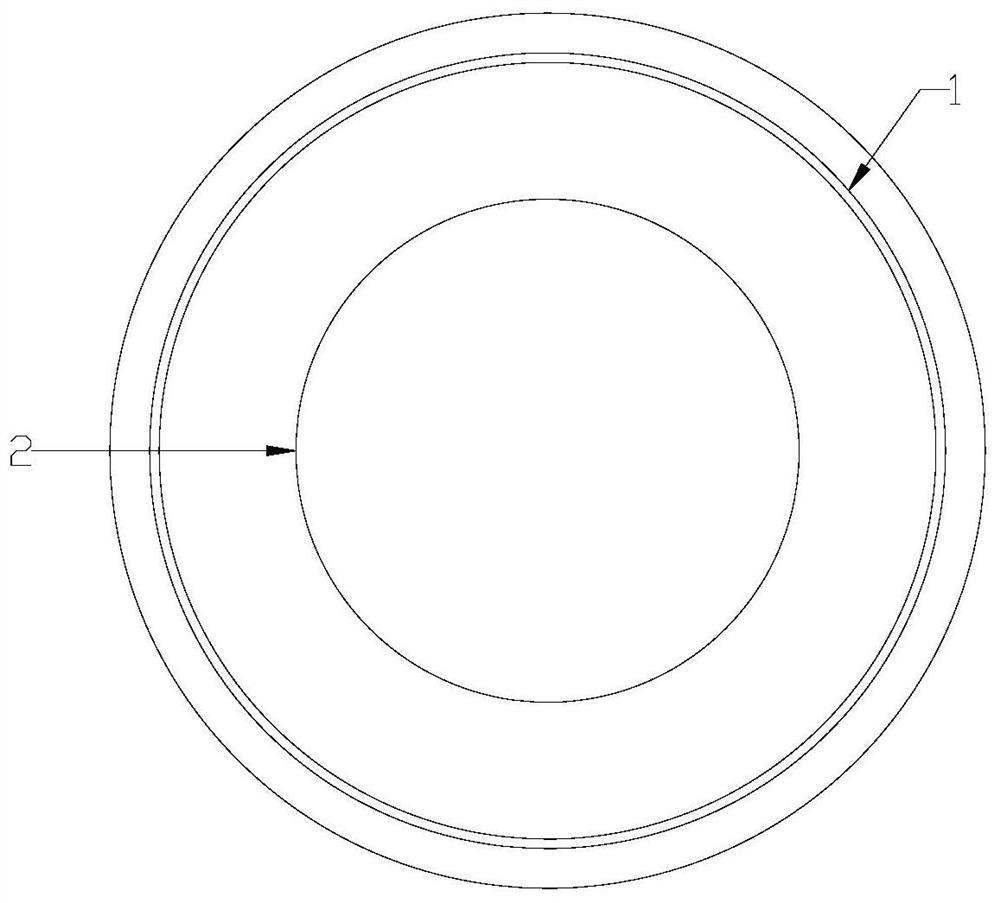

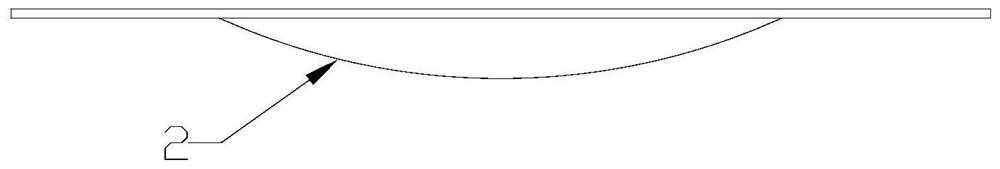

Image

Examples

Embodiment 1

[0027] Weigh 0.02 parts by weight of photocatalytic nano titanium dioxide particles with a coating layer on the surface, 0.002 parts of slow-release ethylene inhibitor, 0.002 parts of binder and 0.02 parts of soluble polymer, stir and mix, and mix Prepared into photocatalytic fresh-keeping paint. Then, the photocatalytic fresh-keeping paint is sprayed on at least one surface of the paper body layer.

[0028] Wherein, the coating layer is silicon dioxide. Preparation method: first, mix 100 parts of nano titanium dioxide and 300 parts of water in a weight ratio, and then fully stir for 10 minutes, then add 1 part of long-chain alkyl surfactant to mix, emulsify for 30 minutes under stirring, and then add ethyl silicate, fully After stirring for 2 h, the mixed solution was finally calcined at 500° C. for 2 h to obtain nano-titania particles coated with silica.

[0029] The sustained-release ethylene inhibitor is a microcapsule ethylene inhibitor. The preparation method of the m...

Embodiment 2

[0036] Weigh out 5 parts by weight of photocatalytic nano titanium dioxide particles with a coating layer on the surface, 0.1 part of slow-release ethylene inhibitor, 5 parts of binder and 0.05 part of soluble polymer.

[0037] The coating layer is montmorillonite. Preparation method: first add 0.8ml of titanium tetrachloride to 40ml of hydrochloric acid solution with a concentration of 1mol / L and stir for 40min to obtain a light yellow and transparent titanium dioxide acidic sol, then add 1% sodium base to 25ml of titanium dioxide acidic sol Montmorillonite solution (1g of montmorillonite was added to a mixture of 50mL deionized water and 50mL absolute ethanol and stirred for 10min) and stirred at 60°C for 4h, followed by centrifugal filtration, washed with deionized water for 3 times, and washed until no more Cl - (detected with 1% AgNO, solution), and then calcined at 500° C. for 2 h to obtain nano-TiO2 particles coated with montmorillonite.

[0038] Others are the same a...

Embodiment 3

[0040] Weigh out 9.5 parts by weight of photocatalytic nano titanium dioxide particles with a coating layer on the surface, 0.18 parts of slow-release ethylene inhibitor, 9.5 parts of binder and 0.09 parts of soluble polymer.

[0041] Others are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com