Method for TBM construction to pass through high-pressure water-rich alteration lens body

A lens and water-rich technology, which is applied in drainage, earthwork drilling, shaft equipment, etc., can solve problems such as tunnel collapse, TBM jamming, sudden mud gushing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

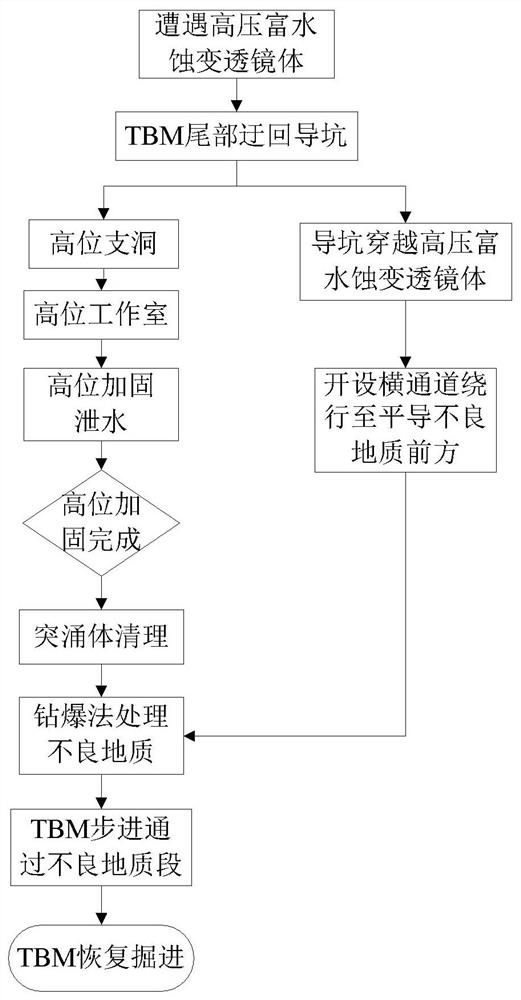

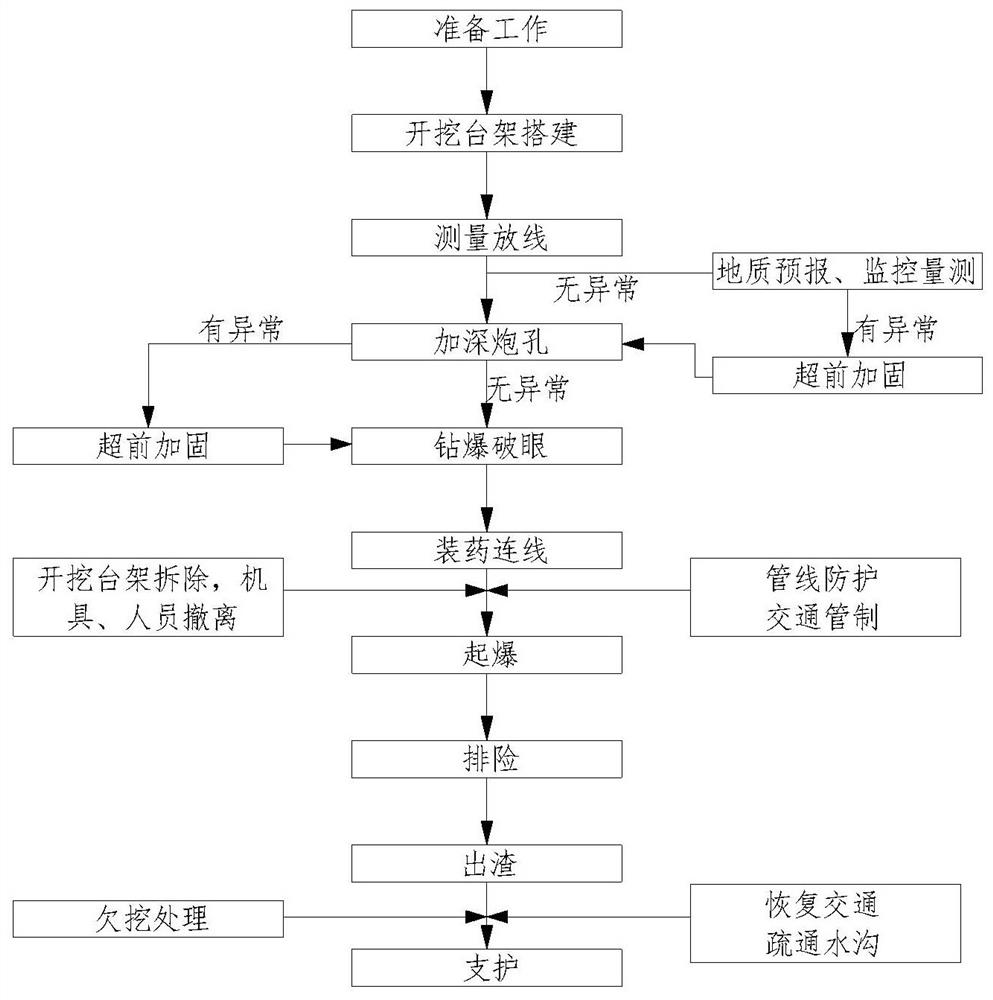

[0040] Example 1: The method of altering the lens body through high-pressure water-rich water in TBM construction

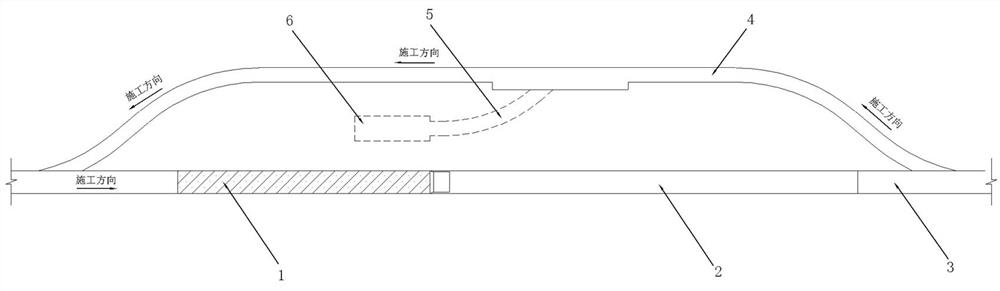

[0041] In August 2019, the TBM construction of the Gaoligongshan Tunnel on the Baoshan-Ruili section of the Dali-Ruili Railway encountered high-pressure rich water alteration lenses. The high pressure at the arch caused the surrounding rock to converge, causing the TBM to jam. At the same time, mud gushing and water gushing occurred at the end of the TBM shield, causing partial burial of the TBM equipment. Measures such as adding a roundabout pilot pit behind the main tunnel of the TBM were used to deal with it. The specific steps are as follows (see figure 1 , figure 2 ):

[0042] 1. Set up pilot pit

[0043] After TBM excavation encounters high-pressure rich water alteration lens or surge, stop TBM excavation and open a pilot pit at the rear of the equipment. The distance between the pilot pit and the main tunnel line is 30m. The opening of the pilot pit is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com