Pre-wire-twisting winding device for repairing high-voltage power transmission conducting wire

A winding device and high-voltage power transmission technology, which is applied in the direction of connection/termination cable equipment, overhead line/cable equipment, etc., can solve the problems of reducing the protection ability of transmission wires, the winding of stress is very laborious, and the safety is low. The disassembly process is convenient and fast, avoiding economic loss, and the effect of tight and firm structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

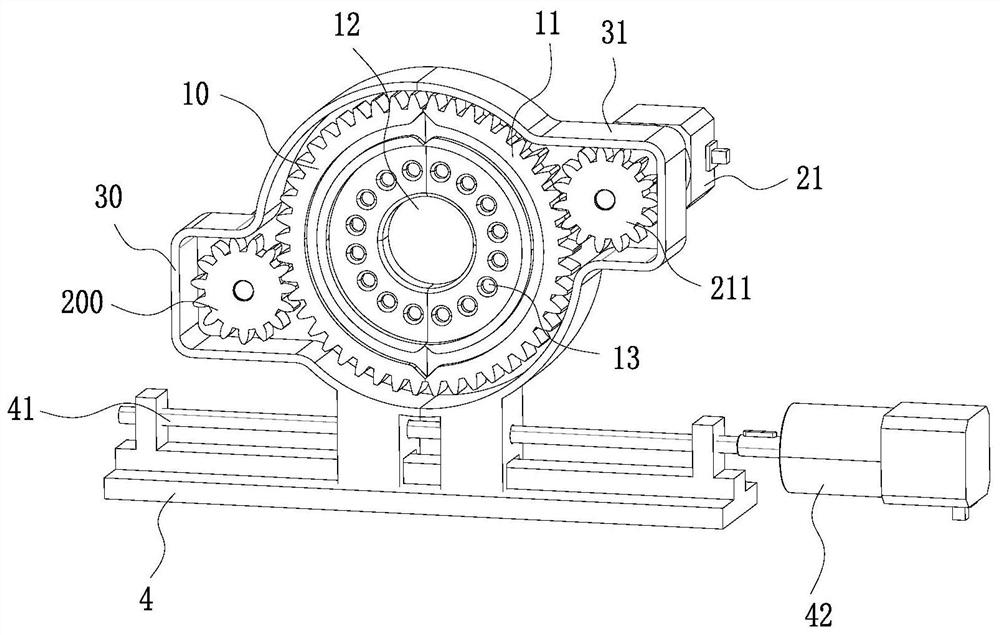

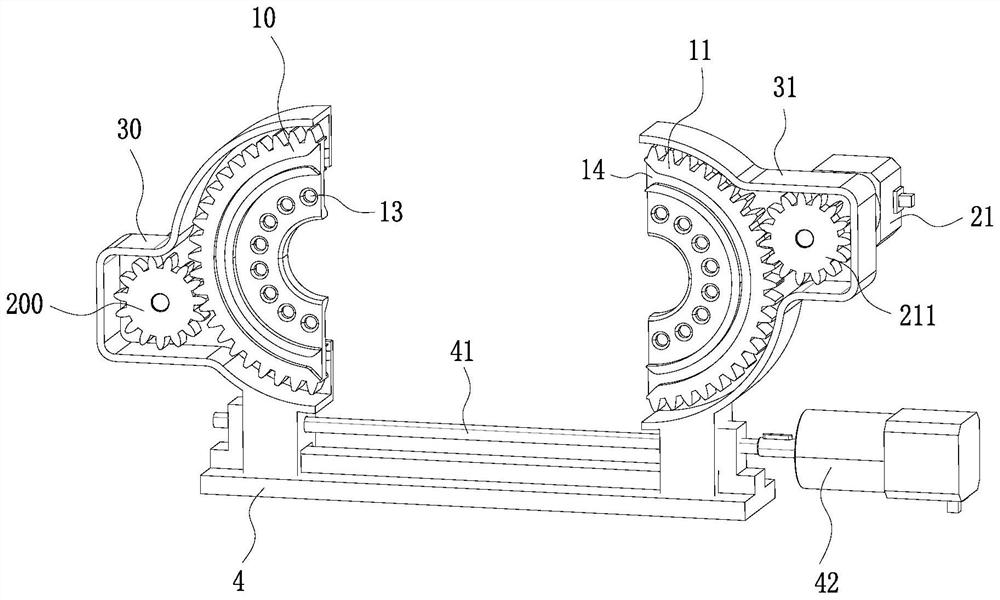

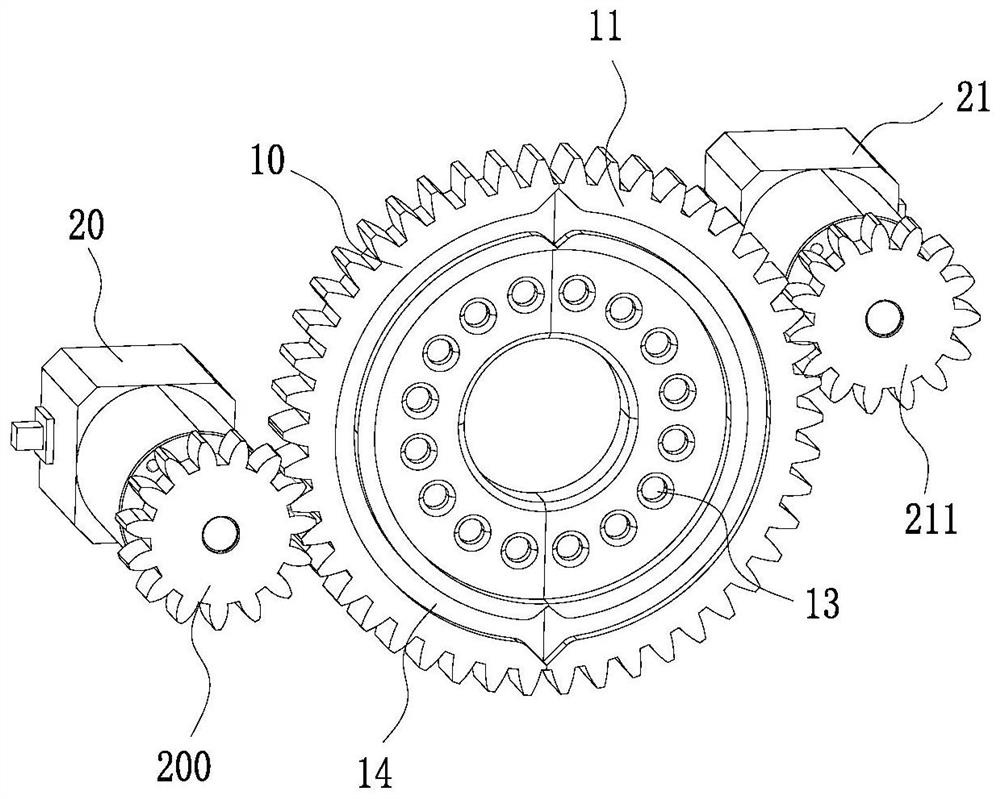

[0030] Such as Figure 1 to Figure 6 As shown, this embodiment shows a pre-twisted winding device for repairing high-voltage transmission wires, including a winch, a winch motor and a mobile platform, and the pre-twisted winding device is used for pre-twisted winding of power transmission wires , the center of the winch is provided with an inner hole 12 for the transmission wire to pass through, and the winch is provided with a plurality of through holes 13 for the pre-twisted wire to pass through, and the through hole 13 is along the inner hole 12 evenly distributed in the circumferential direction, the winches are spliced by mutually symmetrical first semicircular winches 10 and second semicircular winches 11, and the opening and closing of the first semicircular winches 10 and the second semicircular winches 11 make the The power transmission wire is in the inner hole 12, the winch motor controls the winch to rotate along its center of circle, and the moving platform cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com