Corn and soybean strip-shaped compound planting full-plant-protection spraying system

A technology of compound planting and spraying system, which is applied to the device, application, animal husbandry and other directions of capturing or killing insects, can solve the problems such as the unsuitability of the sprayer for corn and soybean interplanting, the difficulty of corn and soybean interplanting application, and the uneven spraying, etc. To achieve the effect of reducing the difficulty of application, convenient application and uniform spraying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

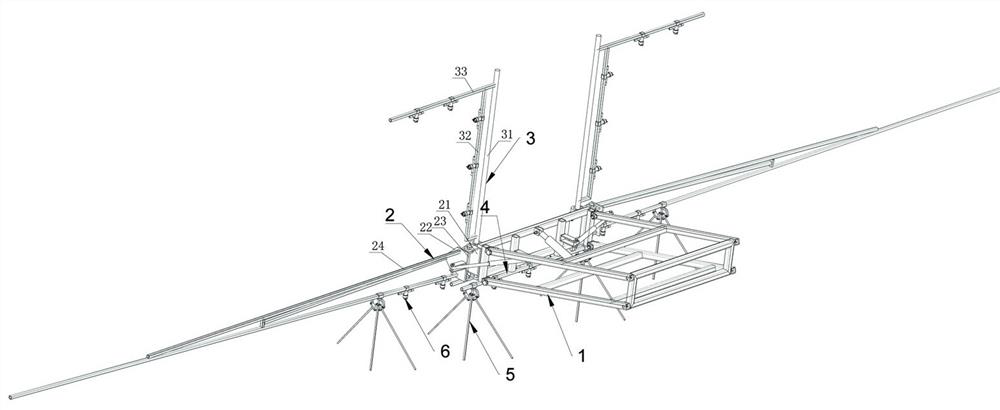

[0033] Embodiment 1: The purpose of this embodiment is to provide a full-process spray boom system for corn and soybean strip compound planting. Under the situation that the new planting mode of corn and soybean interplanting is becoming more and more popular, aiming at the many defects existing in the existing equipment, the present invention proposes A new type of spray mechanism is developed, which can be applied to the interplanting mode of corn and soybean. The specific structure is as follows, as figure 1 with Figure 5 As shown, the present invention includes a power machine and a spraying mechanism installed at the front end or rear end of the power machine. The power machine (tractor, etc.) is used as a power to hold up the spraying mechanism to walk in the field and spray during the movement. This is a commonly used spraying mechanism at present Means, the present embodiment proposes a novel spraying mechanism on the basis of this spraying means.

[0034] The spray ...

Embodiment 2

[0047] Embodiment 2: This embodiment is basically the same as Embodiment 1, the difference is that this embodiment further limits the parallelogram lifting adjustment mechanism.

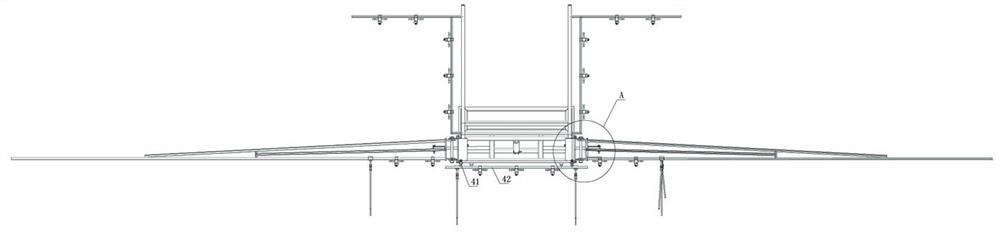

[0048] The lifting mechanism includes two lower swing rods 12 and upper swing rods 13 parallel to each other, a cross beam is arranged at the middle part of the lower swing rod, and the lifting hinge seat 2 is arranged at the middle part of the cross beam

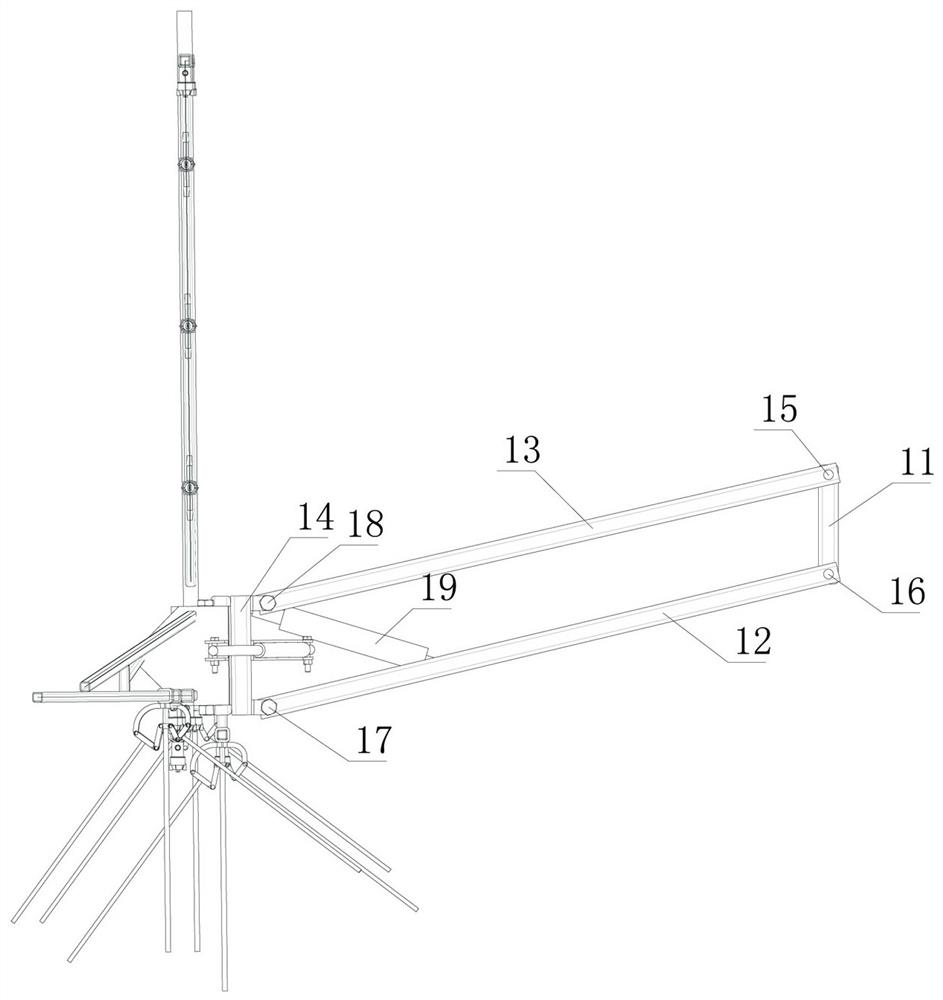

[0049] like Figure 5 As shown, the lower swing rod 12 and the upper swing rod 13 are spliced by multiple high-strength square tubes, and the two ends of the lower swing rod 12 and the upper swing rod 13 are hinged together to form a parallelogram mechanism. The middle part of the lower swing rod 12 is Rectangular hole, and be provided with crossbeam in the middle, lifting hinged seat one 191 is arranged on lifting frame 14, and lifting hinged seat one 191 is at the same height with upper swing rod 13 inner ends, thereby lifting hinged seat two ...

Embodiment 3

[0050] Embodiment 3: This embodiment is basically the same as Embodiment 1, the difference is that this embodiment further limits the three-dimensional turning mechanism.

[0051] like Figure 9 As shown, the upper cross bar 33 is matched and set on the upper part of the main upright bar 31 and the auxiliary upright bar 32 through a sliding sleeve at the same time, and can slide along the two. The vertical height of the upper cross bar 33 can be adjusted, that is, the height of the upper horizontal nozzle group 632 relative to the upper end of the corn, so that it is suitable for the height of the corn in different periods, and the height of the middle cross bar 42 relative to the soybeans can be adjusted by the parallelogram lifting adjustment mechanism. Height, the lifting adjustment of this embodiment is used in conjunction with the parallelogram lifting adjustment mechanism, so that the nozzle is at the optimum distance from the crop surface in the later stage of corn and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com