Automobile stamping die with discharging device

A stamping die and discharge device technology, applied in the field of stamping dies, can solve the problems of increased scrap rate, low safety factor of manual discharge, and particles prone to mold, and achieve the effect of eliminating potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

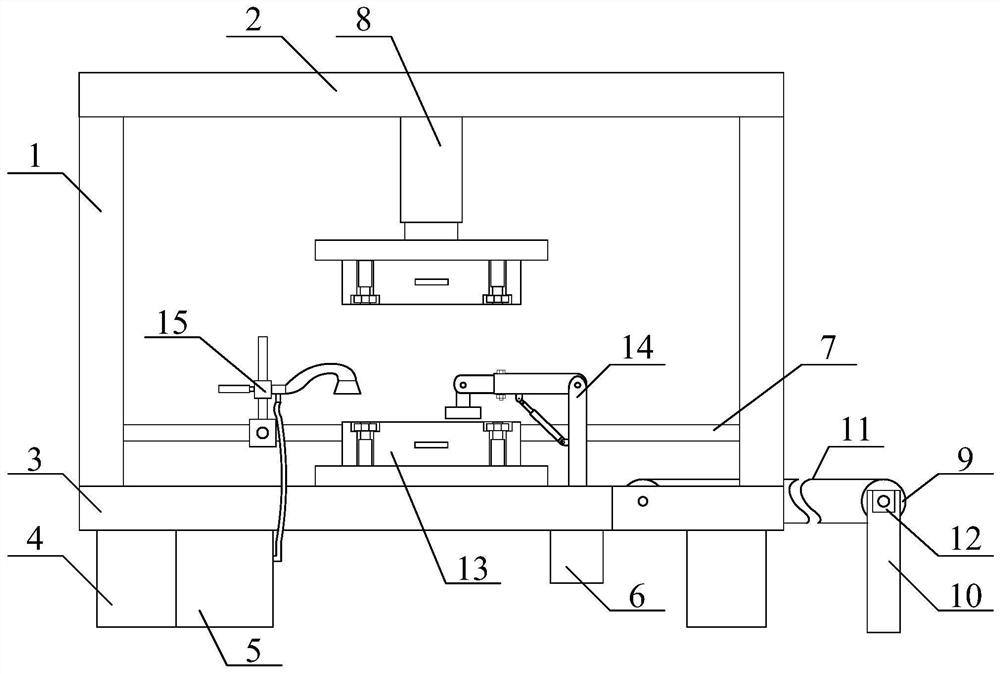

[0035] The present invention is described in detail below in conjunction with accompanying drawing:

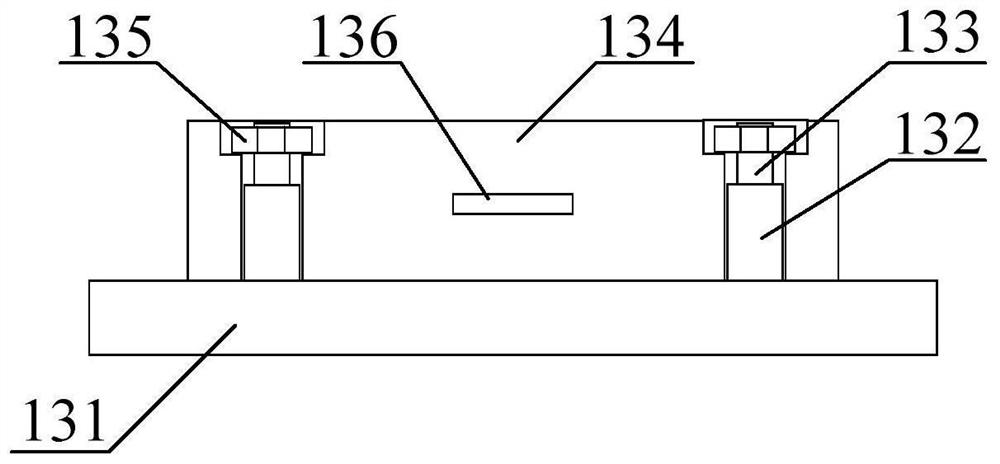

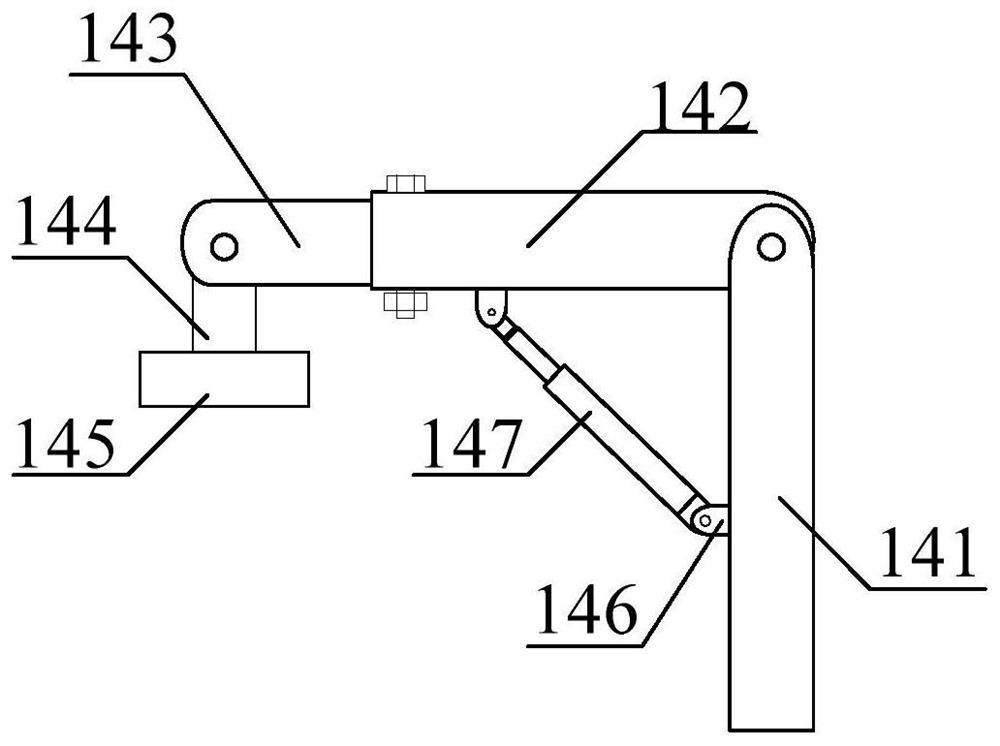

[0036] as attached figure 1 And attached figure 2As shown, a kind of automobile stamping die with discharging device according to the present invention includes a support rod 1, a top plate 2, a workbench 3, a support leg 4, a pneumatic transmission station 5, a motor 6, a guide rod 7, and a cylinder 8. Conveyor roller 9, support plate 10, transmission belt 11, motor 2 12, mold convenient positioning installation rod structure 13, damage-proof discharge rod structure 14 and adjustable mobile blowing pipe structure 15, and the support rods 1 are respectively bolted at one end Connected to the four corners of the lower end of the top plate 2, and the other end is bolted to the four corners of the upper end of the workbench 3; the four corners of the lower end of the workbench 3 are respectively bolted to support legs 4; the pneumatic transmission station 5 is separately instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com