Band sawing machine for production of furniture

A band sawing machine and furniture technology, applied in band saws, sawing components, manufacturing tools, etc., can solve the problems of inability to cut wood at different angles, high safety hazards, etc., to reduce the number of placements, ensure safety, reduce costs and The effect of space occupancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

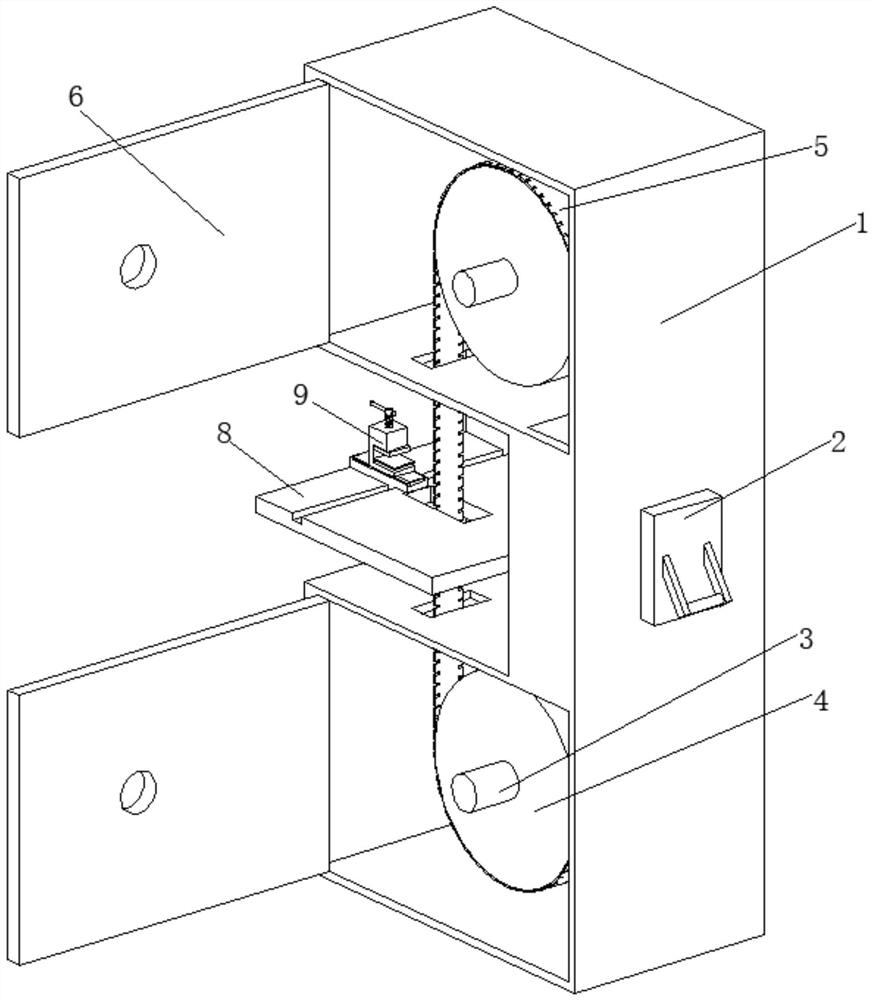

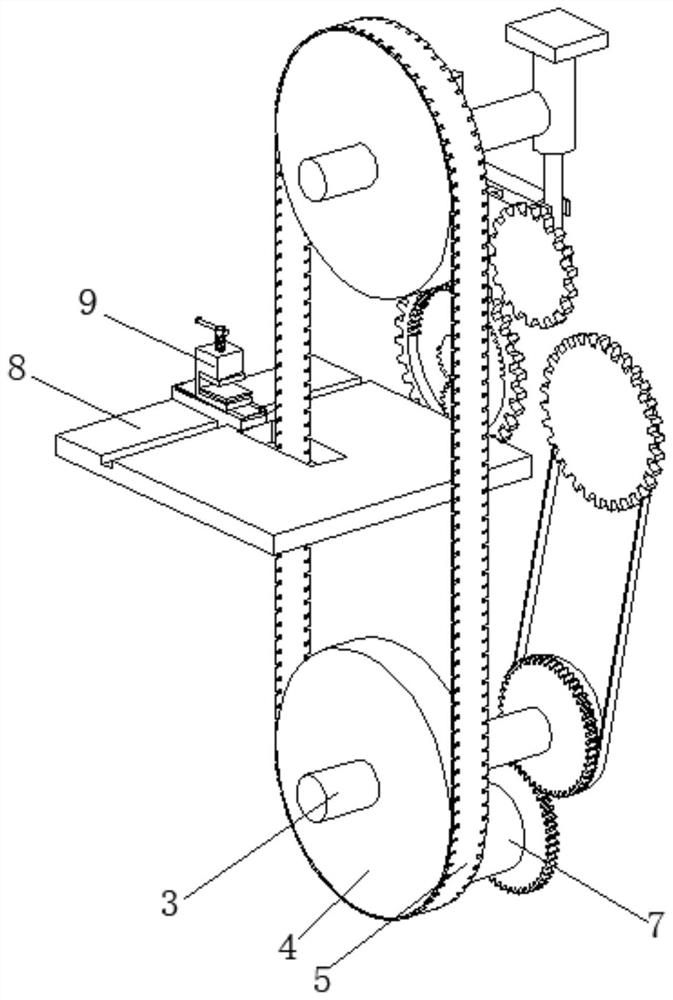

[0030] A band sawing machine for furniture production, such as Figure 1-Figure 5 As shown, it includes a box body 1, the right side of the box body 1 is connected with a switch knife 2 by bolts, the inner wall of the box body 1 is rotatably connected with two rotating shafts 3, the surface of the rotating shaft 3 is clamped with a turntable 4, and the two turntables 4 The surface is connected through the transmission of the saw band 5, the inner wall of the box body 1 is rotatably connected with two revolving doors 6, and the inner wall of the revolving door 6 is rotatably connected with the surface of the rotating shaft 3, the inside of the box body 1 is provided with a transmission mechanism 7, and the box body 1 The surface of the table is rotatably connected with a workbench 8, and the surface of the workbench 8 is provided with a fixing mechanism 9.

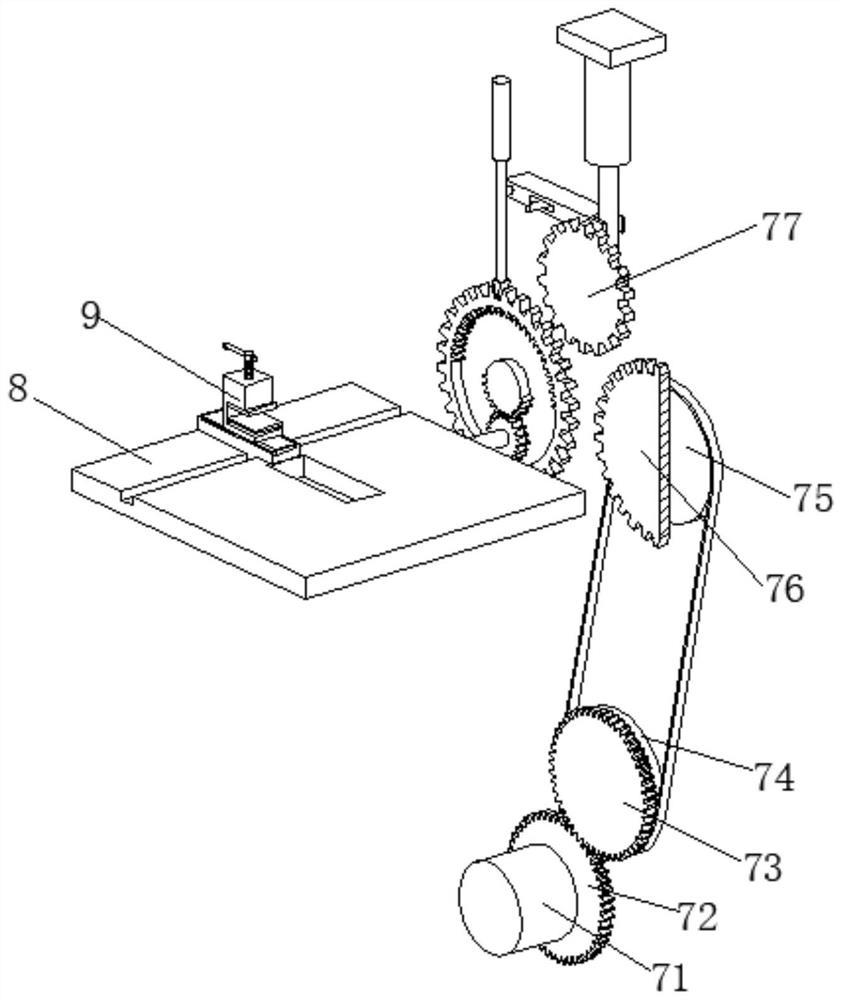

[0031] In this embodiment, the transmission mechanism 7 includes a motor 71, the output end of the motor 71 is clamped wi...

Embodiment 2

[0040] Such as Figure 5-Figure 7 As shown, on the basis of Embodiment 1, in this embodiment, the surface of the slide plate 92 is slidingly connected with the inner wall of the slide block 95, and the top of the fixed block 91 is provided with a mounting device 93, and the slide plate 92 can be moved left and right on the slide block 95. Sliding, so that the cutting position can be adjusted freely, the practicability is greatly increased, the operation is convenient and simple, and it is beneficial to popularize and use.

[0041] The installation device 93 includes a screw rod 931, the inside of the screw rod 931 is movably connected with a push rod 932, the bottom end of the screw rod 931 is rotatably connected with an upper pressing plate 933, the inner wall of the slide plate 92 is movably connected with a fixed spring 935, and the top of the fixed spring 935 is welded with a fixed Column 934, the top of the fixed column 934 is welded with a lower pressure plate 936.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com