Pipe overturning and conveying platform device

A platform device and pipe turning technology, which is applied to the field of pipe turning and feeding platform devices, can solve the problems of troublesome packaging and bundling, time-consuming and laborious, and personnel are prone to mistake the number of roots, and achieve the effect of preventing rework.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

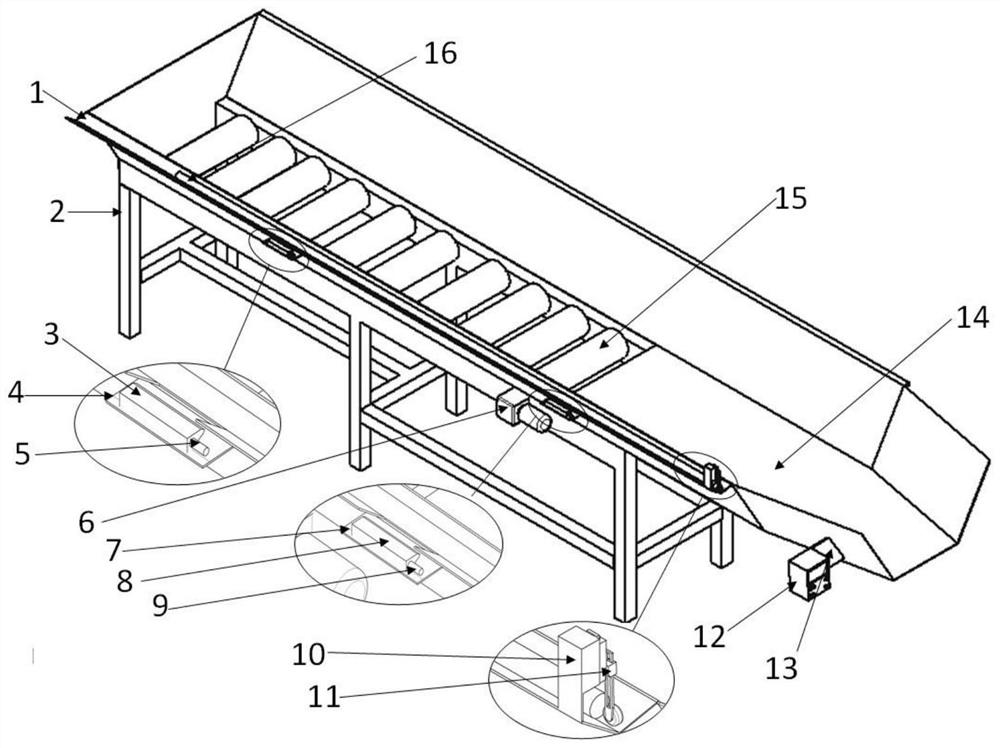

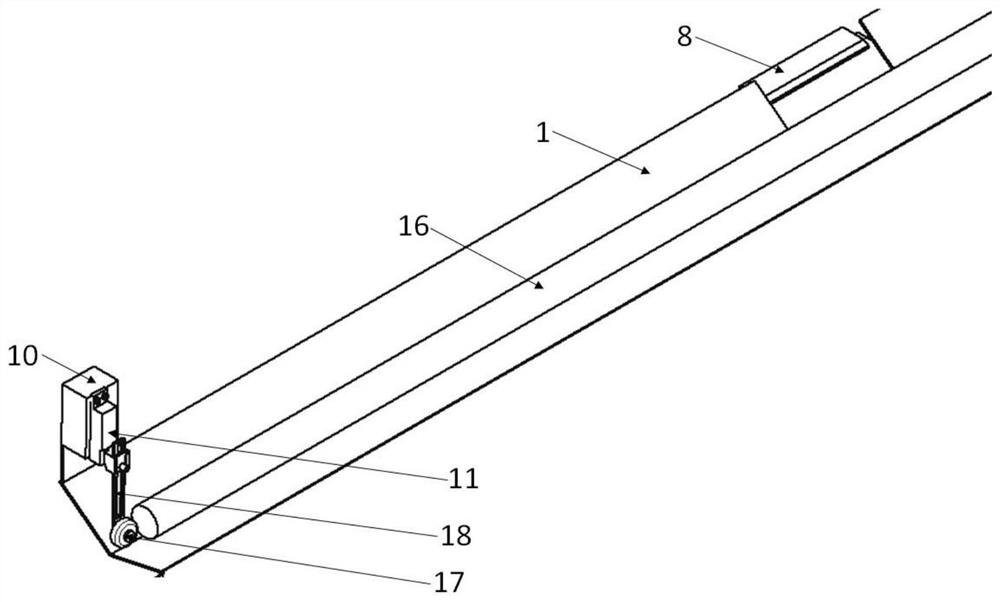

[0042] Please see attached figure 1 with 2 , a pipe turning platform device, characterized in that it mainly includes a bracket 2 and a platform body 14, the bracket 2 is welded by a plurality of thickened steel pipes, and the platform body 14 adopts a closing design and is welded by a plurality of thickened stainless steel plates The bracket 2 and the table body 14 are connected by welding; the left table of the table body 14 adopts a hollow design, and a plurality of tube delivery rubber wheels 15 are connected to the bracket 2 through threads at the hollowed out part, and the top of the tube delivery rubber wheels 15 is slightly higher On the table on the right side of the table body 14; the tube delivery motor 6 and the tube delivery rubber wheel 15 are connected through gears and chains to realize linkage.

[0043] The pipe conveying trough 1 is formed by bending a stainless steel plate, and is connected with the table body 14 by welding.

[0044] The air knife fixed pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com