Method for adjusting heating system of coke oven after increasing gas coal and/or lean coal proportioning

An adjustment method and lean coal technology, applied in the heating of coke ovens, combustible gas heating coke ovens, coke ovens, etc., can solve the problems of blind adoption, difficulty in ensuring that the volatile content of coke is less than 1.3%, and prolonging the coking time. Uniform maturity, good coke strength, and significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Example 1: A coke enterprise 6m coke oven

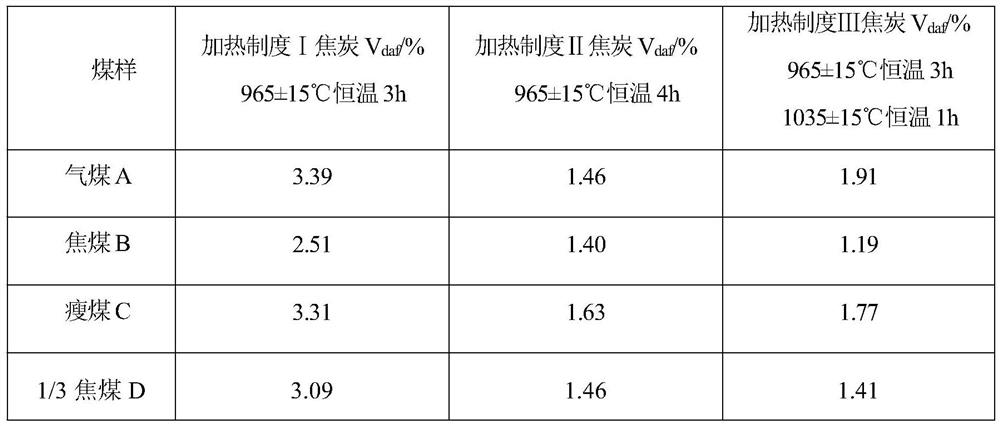

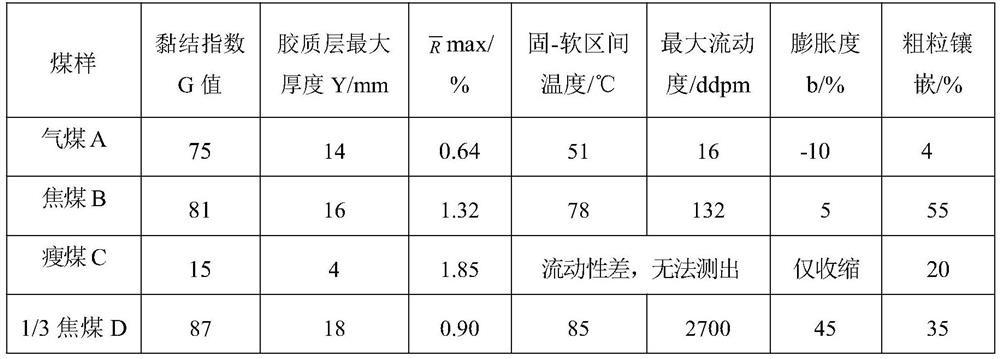

[0037] 1) Basic coking coal ratio: Thinning coal with 10%, gas coal ratio is 10%, coal coal equipped ratio of 58%, 1 / 3 coking coal with 22%. The coal quality index of the thin coal is: the average maximum reflectance of the mirror group MAX is 1.65%, and the Austrian expansion test is only shrinkage; the coal coal index of the gas is: the average maximum reflectivity of the mirror group MAX is 0.75%, the Auba Expansion value is -5%, the maximumiths flow degree LGMF is 2.03, the glue layer volume curve is a smooth drop type; the coal coal-coal quality index is: the average maximum reflectivity of the mirror group MAX is 1.25%, the maximum basellide LGMF is 2.75, the coarse mosaic structure is 60%; the 1 / 3 coking coal coal-index: the average maximum reflectance of the mirror group MAX is 0.90%, the maximum thickness Y value of the collant layer is 18mm, the Ocon expansion is 70%, the maximum kthlous fluidity LGMF is 3.51, the soli...

Embodiment 2

[0041] Example 2: A coke enterprise 7m coke oven

[0042] 1) Basic coking coal ratio: Thin coal with 8%, gas coal ratio 8%, coking coal with 54%, 1 / 3 coking coal with 30%. The coal quality index of the thin coal is: the average maximum reflectance of the mirror group MAX is 1.70%, and the Oya Expansion is tested to shrink only; the coal coal index of the gas is: the average maximum reflectivity of the mirror group MAX is 0.70%, the Ocon Expansion B value is -10%, the maximum basellomatic LGMF is 2.50, the gum layer volume curve is a smooth drop shape; the coal coal index of the coal coal is: the average maximum reflectivity of the mirror group MAX is 1.28%, the maximum baselloma LGMF is 2.81, the coarse mosaic structure is 65%; the 1 / 3 coking coal coal index is: the average maximum reflectivity of the mirror group MAX is 0.87%, the maximum thickness y value of the collast layer is 18mm, the Ocon expansion is 65%, the maximum base fluctuation degree LGMF is 3.30, the solid-soft...

Embodiment 3

[0047] Example 3: A coke enterprise 7.63m coke oven

[0048] 1) Basic coking coal ratio: 3% thinning coal with a coal coal ratio, a coal coal equipped ratio of 56%, 1 / 3 coking coal with 27%. The coal quality index of the thin coal is: the average maximum reflectance of the mirror group The max is 1.69%, and the Oya Expansion is tested to shrink only; the coal coal index of the gas is: the average maximum reflectivity of the mirror group MAX is 0.75%, the Auba Expansion value is -5%, the maximumiths flow degree LGMF is 2.03, the glue layer volume curve is a smooth drop type; the coal coal-coal quality index is: the average maximum reflectivity of the mirror group MAX is 1.25%, the maximum basellide LGMF is 2.75, the coarse mosaic structure is 60%; the 1 / 3 coking coal coal-index: the average maximum reflectance of the mirror group MAX is 0.90%, the maximum thickness Y value of the collant layer is 18mm, the Ocon expansion is 70%, the maximum kthlous fluidity LGMF is 3.51, the so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com