A kind of coconut nut cookie and preparation method thereof

A coconut nut and coconut technology is applied in the directions of freeze-drying of dough, pre-baked dough treatment, baking, etc., which can solve the problems of uneven baking, over-burning, low qualified rate of finished products, etc., and achieve rich taste, crisp taste, Flavorful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

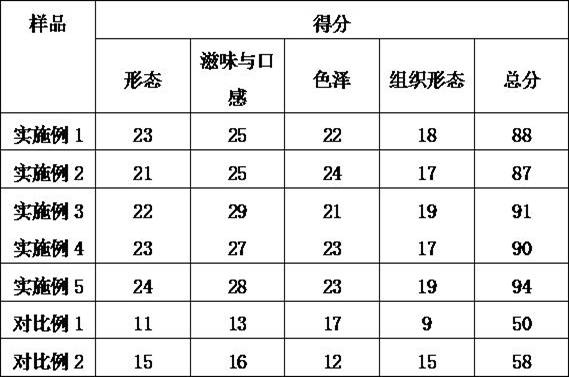

Embodiment 1

[0029] A coconut nut cookie, the raw materials are: 1 part of flour, 0.2 part of margarine, 0.1 part of butter, 0.02 part of palm oil, 0.4 part of coconut milk, 0.04 part of minced coconut, 0.05 part of whole egg liquid, 0.003 part of baking soda, carbonic acid 0.003 part of ammonium hydrogen, 0.02 part of wheat starch, 0.35 part of white sugar, 0.4 part of almond, 0.07 part of plant composition, and 0.1 part of milk powder.

[0030] The plant composition is: toi toi flower, dried reed rhizome and perilla seed in a weight ratio of 3:3:2; the preparation steps of the plant composition include: (1) ultrasonic extraction: weigh the toi toi flower, dried Reed rhizome and perilla seeds were crushed into 200 meshes, added pure water 8 times the weight of the raw materials, set the ultrasonic frequency to 50kHz, kept the extraction pot at a constant temperature of 55°C, extracted for 50 minutes and then centrifuged to obtain the plant extract; (2) Concentrate Drying: The above-mentio...

Embodiment 2

[0041] A coconut nut cookie, the raw materials are: 1 part of flour, 0.45 part of margarine, 0.25 part of butter, 0.04 part of peanut oil, 0.25 part of coconut milk, 0.06 part of minced coconut, 0.06 part of whole egg liquid, 0.002 part of baking soda, bicarbonate 0.005 parts of ammonium, 0.05 parts of wheat starch, 0.4 parts of white sugar, 0.3 parts of peanut kernels, 0.05 parts of plant composition, and 0.2 parts of milk powder.

[0042] The plant composition is: toi toi flower, dried reed rhizome, and perilla seed in a weight ratio of 5:4:3; the preparation steps of the plant composition include: (1) ultrasonic extraction: weigh the toi toi flower, dried Reed rhizome and perilla seeds were crushed into 200 meshes, added pure water 8 times the weight of the raw materials, set the ultrasonic frequency to 50kHz, kept the extraction pot at a constant temperature of 55°C, extracted for 50 minutes and then centrifuged to obtain the plant extract; (2) Concentrate Drying: The abov...

Embodiment 3

[0053] A coconut nut cookie, the raw materials are: 1 part of flour, 0.3 part of margarine, 0.2 part of butter, 0.03 part of soybean oil, 0.2 part of coconut milk, 0.05 part of minced coconut, 0.07 part of whole egg liquid, 0.001 part of baking soda, carbonic acid Ammonium hydrogen 0.004 part, wheat starch 0.03 part, white sugar 0.2 part, almond 0.5 part, plant composition 0.12 part, milk powder 0.08 part.

[0054] The plant composition is: toi toi flower, dried reed rhizome, and perilla seed in a weight ratio of 4:5:3; the preparation steps of the plant composition include: (1) ultrasonic extraction: weigh the toi toi flower, dried Reed rhizome and perilla seeds were crushed into 200 meshes, added pure water 8 times the weight of the raw materials, set the ultrasonic frequency to 50kHz, kept the extraction pot at a constant temperature of 55°C, extracted for 50 minutes and then centrifuged to obtain the plant extract; (2) Concentrate Drying: The above-mentioned plant extract ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com