Brewing process of strong aromatic Chinese spirits

A technology of Luzhou-flavor liquor and technology, which is applied in the field of brewing technology of Luzhou-flavor liquor, can solve the problems of liquor quality decline, aftertaste shortening, alcohol easy to pass through, etc., and achieve fast reaction speed, soft entrance and rich aroma Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

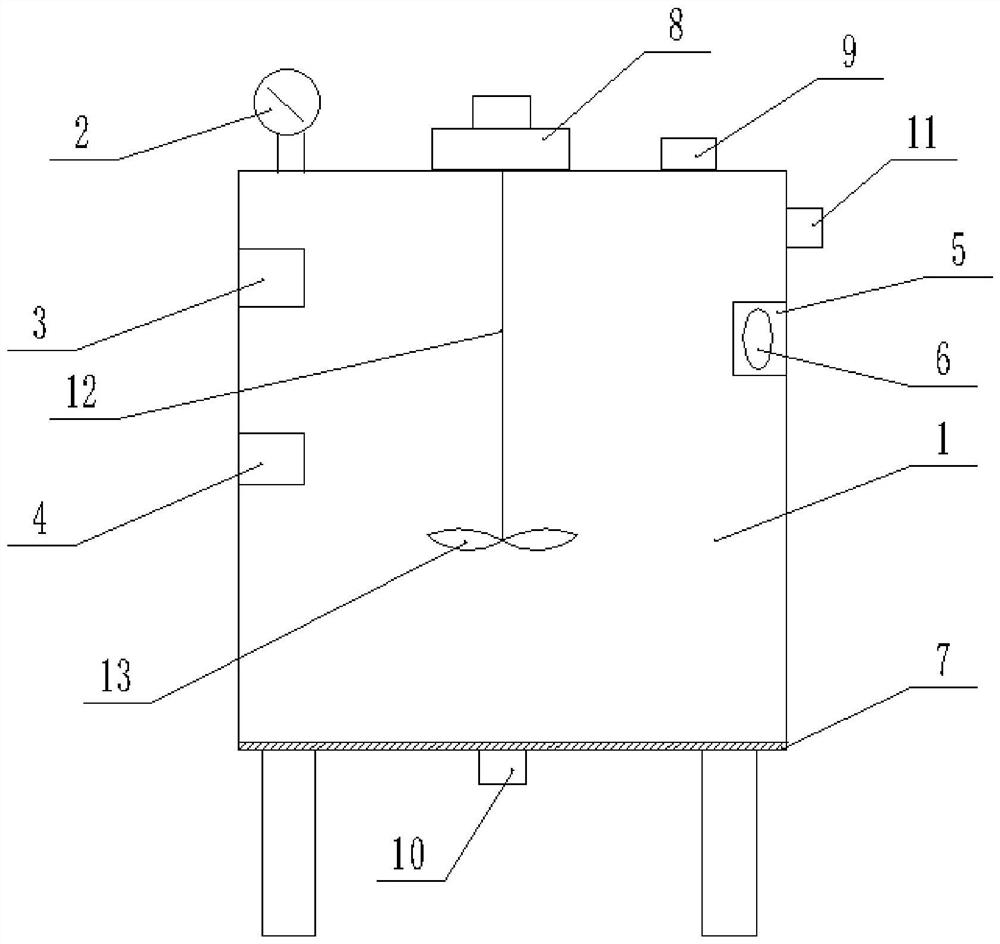

Method used

Image

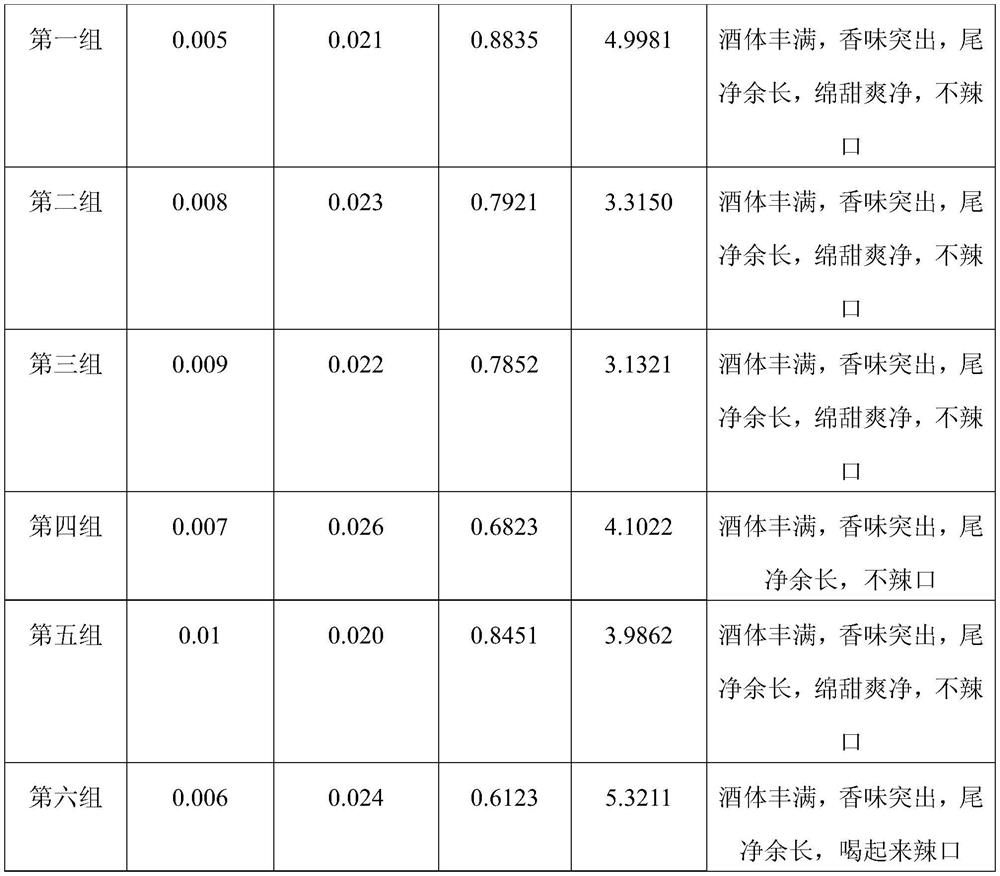

Examples

Embodiment 1

[0036] The present embodiment provides a kind of brewing technique of Luzhou-flavor liquor, and this brewing technique comprises the following steps:

[0037] (1) Preparation of wine-making main ingredients: prepare wine-making main ingredients according to the following parts by weight: 20 parts of sorghum, 15 parts of japonica rice, 10 parts of barley, 12 parts of corn and 6 parts of oats;

[0038] (2) Cooking grain: Put corn, sorghum and barley in order from bottom to top in steamer A, add water to 1cm above the grain surface, and then steam for cooking; take another steamer B, Put oats and japonica rice in steamer B from bottom to top, add water to 1cm above the surface of the grain, and then steam for cooking. After cooking, mix the materials in steamer A and steamer B to obtain mixed grain, and then Add peach juice water of 0.3 times the weight of the mixed grain to moisten the grain; among them, steamer A cooks the grain by steaming until it boils, keeps boiling for 10 ...

Embodiment 2

[0043] The present embodiment provides a kind of brewing technique of Luzhou-flavor liquor, and this brewing technique comprises the following steps:

[0044] (1) Preparation of wine-making main ingredients: prepare wine-making main ingredients according to the following parts by weight: 25 parts of sorghum, 20 parts of japonica rice, 12 parts of barley, 18 parts of corn and 8 parts of oats;

[0045] (2) Cooking grain: Put corn, sorghum and barley in the steamer A in a tiled manner from bottom to top, add water to 1.2cm above the grain surface, and then steam for cooking; take another steamer B, Put oats and japonica rice in steamer B from bottom to top, add water to 1.2cm above the surface of the grain, and then steam for cooking. After cooking, mix the materials in steamer A and steamer B to obtain a mixed grain , and then add peach juice water with an amount 0.3 times the weight of the mixed grain to moisten the grain; among them, the cooking method of the steamer A is to s...

Embodiment 3

[0050] The present embodiment provides a kind of brewing technique of Luzhou-flavor liquor, and this brewing technique comprises the following steps:

[0051] (1) Preparation of wine-making main ingredients: prepare wine-making main ingredients according to the following parts by weight: 30 parts of sorghum, 25 parts of japonica rice, 15 parts of barley, 22 parts of corn and 12 parts of oats;

[0052] (2) Cooking grain: Put corn, sorghum and barley in the steamer A in a tiled manner from bottom to top, add water to 1.5cm above the grain surface, and then steam for cooking; take another steamer B, Put oats and japonica rice in steamer B from bottom to top, add water to 1.5cm above the surface of the grain, and then steam for cooking. After cooking, mix the materials in steamer A and steamer B to obtain a mixed grain , and then add peach juice water with an amount 0.4 times the weight of the mixed grain to moisten the grain; among them, the cooking method of the steamer A is to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com