Full-automatic immersion-free quenching mechanism for roller furnace steel cylinders

A fully automatic, roller bar furnace technology, applied in the direction of quenching device, furnace type, furnace, etc., can solve the problems of inconvenient processing of steel cylinders, affecting the uniformity of quenching of steel cylinders, reducing the quality of quenching of steel cylinders, etc. The effect of drenching and quenching, the effect of realizing automatic work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following examples are for illustrative purposes only and are not intended to limit the scope of the invention.

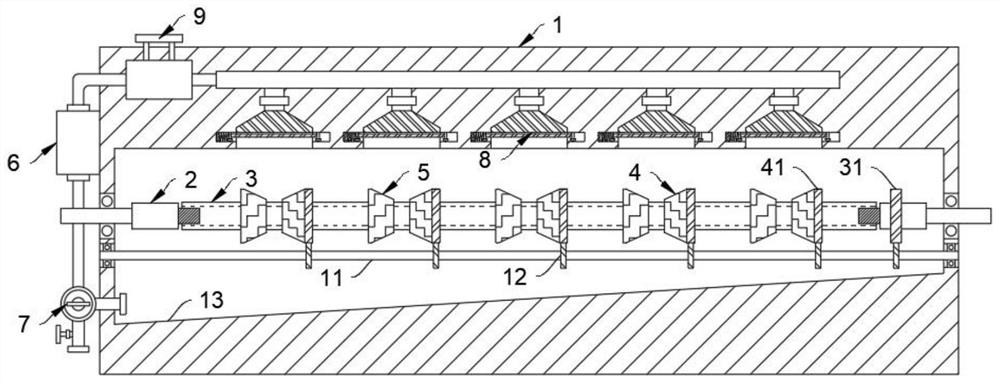

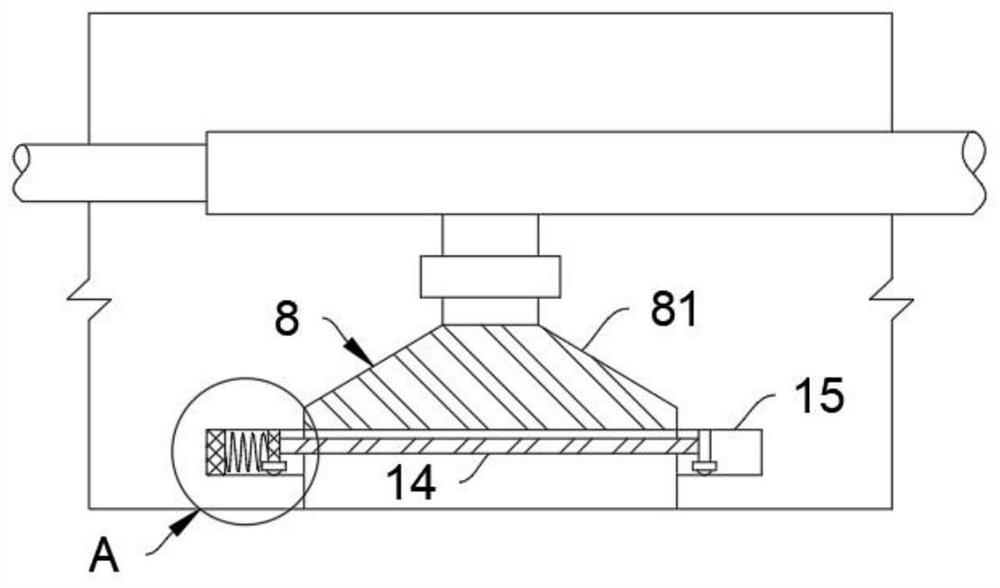

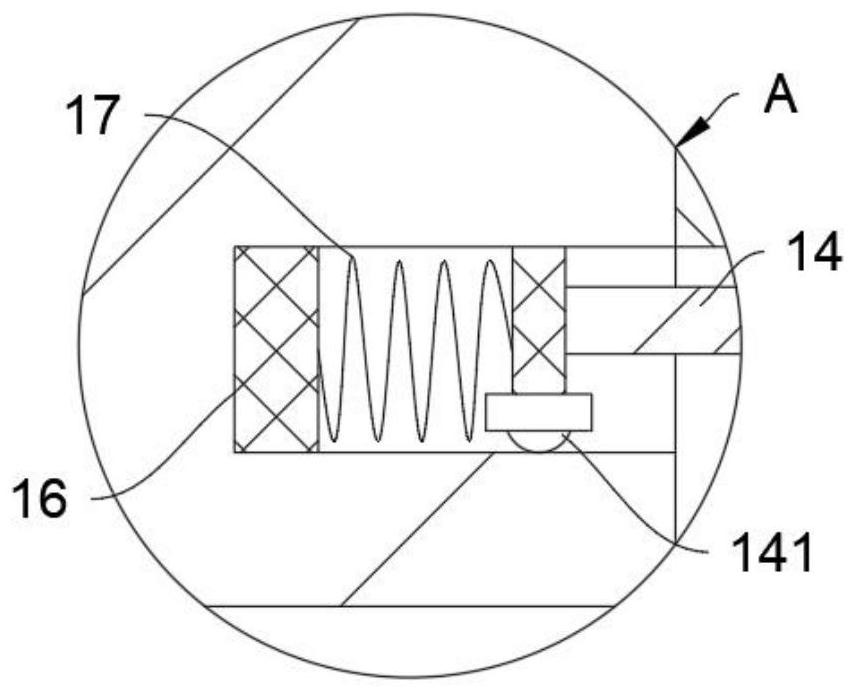

[0027] like Figure 1-5 As shown, a fully automatic non-immersion quenching mechanism for steel cylinders in a roller furnace includes a box body 1, and the box body 1 is rotatably connected with an idler assembly 2, and the idler assembly 2 includes a rotating shaft 3, a rotating idler 4 and a movable Idler 5, it should be noted that the diameter of a group of end surfaces where the rotating idler 4 and the movable idler 5 are close to each other is 65mm, and the diameter of a group of end surfaces where the rotating idler 4 and the movable idler 5 are far away from each other is 102mm The lengths of the rotating idler 4 and the movable idler 5 are both 45 mm, and the surfaces of the rotating idler 4 and the movable idler 5 are provided with anti-slip lines, and the directions of the anti-slip lines of the adjacent rotating idler 4 and the movable idler...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com