Concrete box girder internal mold disassembly-free supporting system and construction method

A concrete box girder and support system technology, which is applied in the field preparation of formwork/formwork/work frame, pillars, and building components, etc., can solve the problems of heavy steel formwork, low construction efficiency, and low rigidity, and achieve enhanced The effect of carrying capacity, improving work efficiency, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

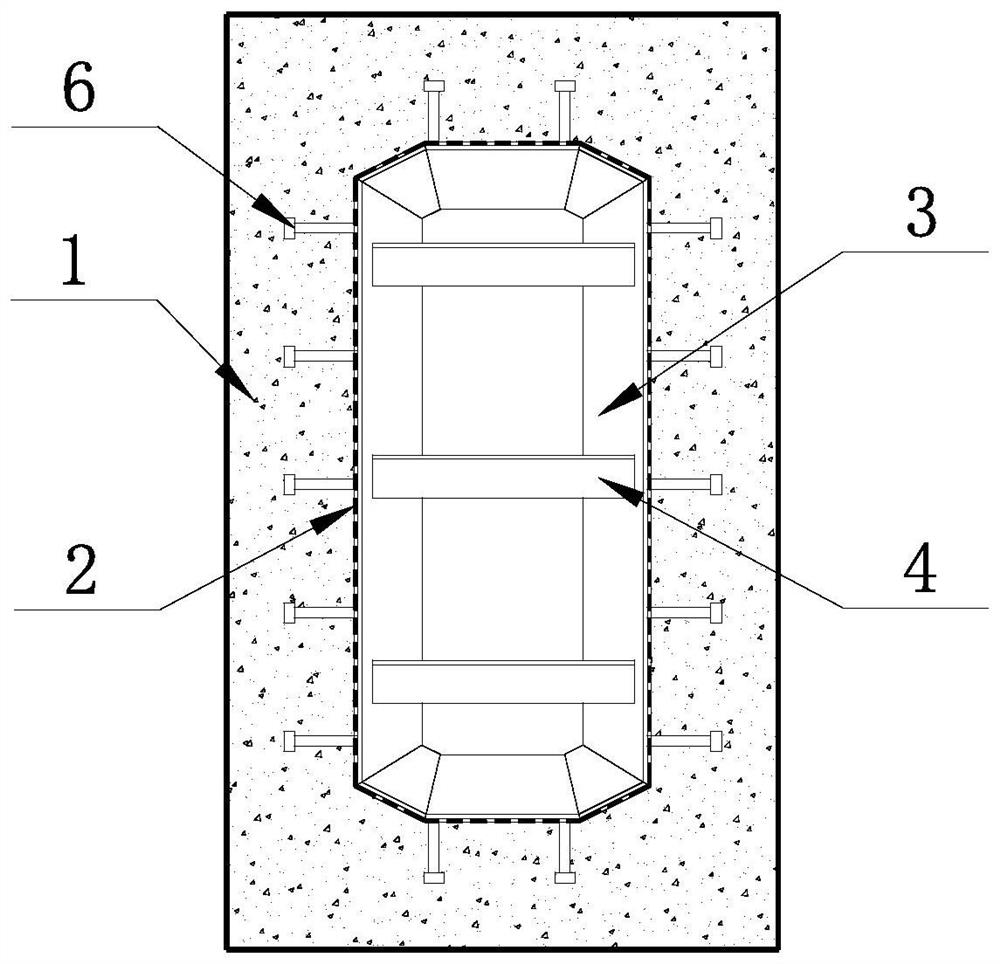

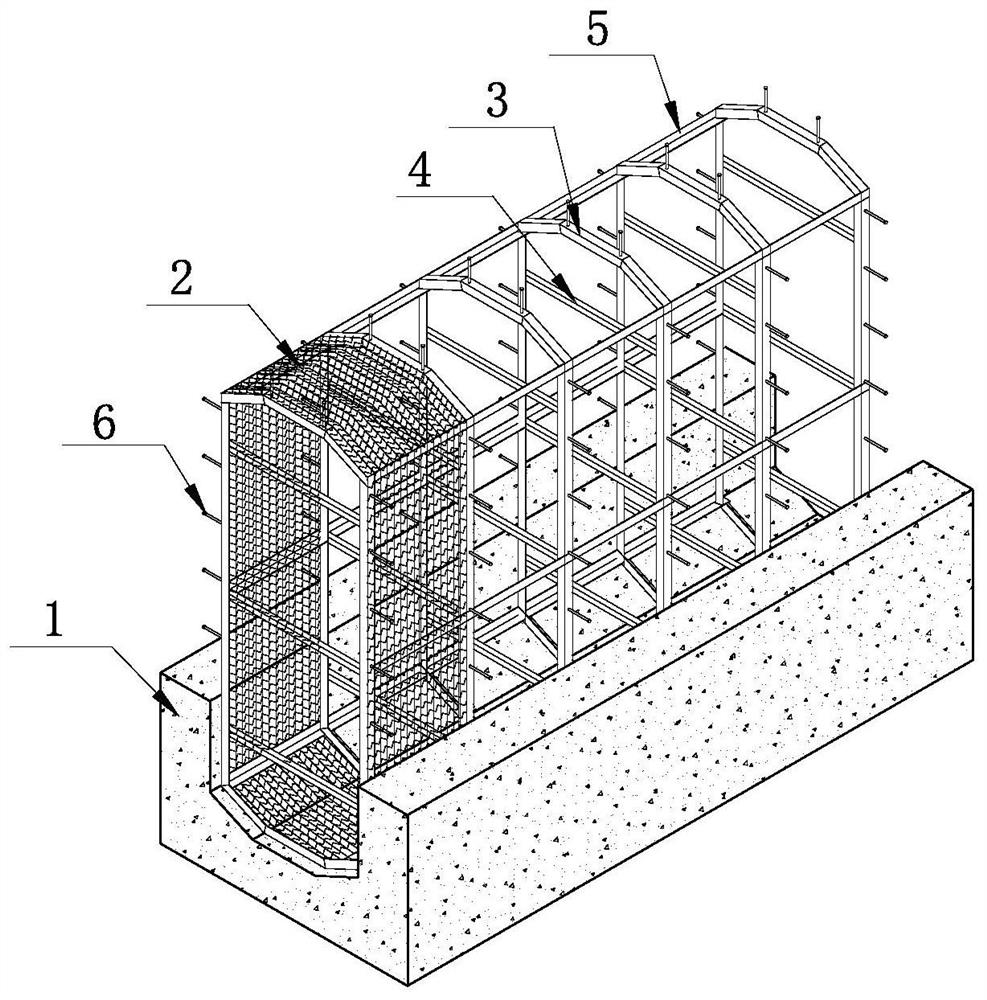

[0023] like figure 1 , figure 2 . The support system of the concrete box girder includes angle steel support frames 3 , transverse supports 4 , longitudinal supports 5 and pegs 6 . The support system plays the role of supporting the formwork during the pouring of the concrete box girder. After the concrete box girder is formed, the support system remains in the inner cavity of the box girder without demolition, and participates in the stress of the box girder.

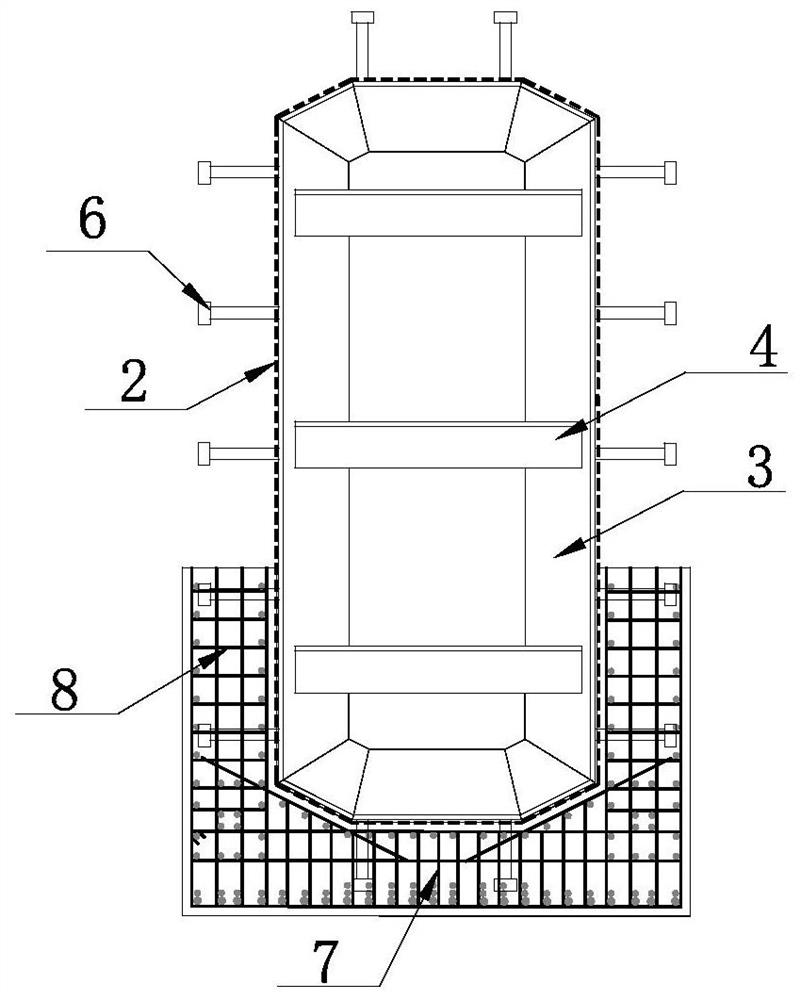

[0024] Formwork processing and manufacturing, such as image 3 ; The support system includes an angle steel support frame 3, a horizontal support 4 and a vertical support 5. The section of the angle steel support frame 3 is L75×5, the height and shape of the angle steel support frame 3 are determined according to the size of the inner cavity of the box girder, and the angle steel s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com