A screw drill that is easy to disassemble and assemble

A screw drilling tool and feed screw technology, applied in the direction of drilling tools, drill pipes, drill pipes, etc., can solve the problem that the screw drilling tool cannot be cooled uniformly and timely, the drill bit is inconvenient to disassemble, maintain and adjust, and affect the normal operation of the screw drilling tool Operation and other problems, to achieve the effect of uniform and effective cooling, convenient disassembly and maintenance, and convenient cooling and cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

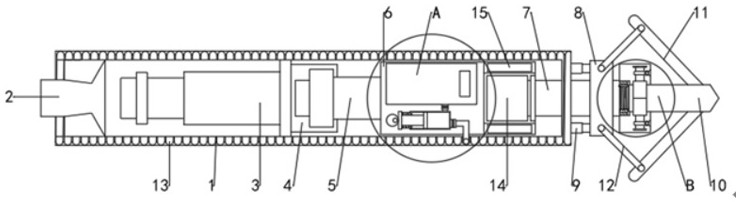

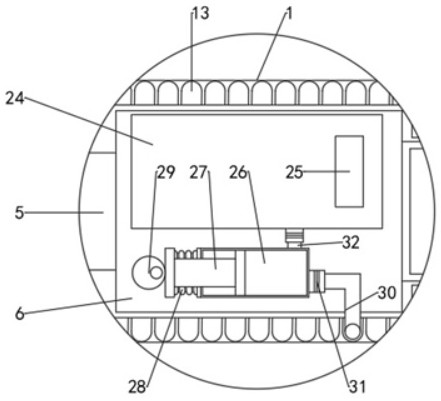

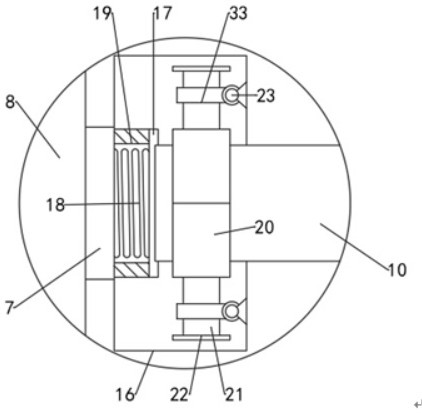

[0020]SeeFigure 1-4A screw drill that is easy to disassemble, including a cylindrical body 1, and the tip end of the cylindrical body 1 is mounted, and the internal portion of the cylinder 1 is sequentially mounted with a drill motor 3, a universal shaft 4, a rotating shaft. 5 and the drill bit 10, the drill bit 10 is driven with the rotating shaft 5, and the rotation shaft 5 is mounted via the tool holder 16 and the drill bit 10; the tool holder 16 is slidably mounted, and the substrate 17 and the tool holder 16 are connected to a limited position. The spring 18, the substrate 17 matches the drill bit 10, and the interior spaced between the tool holders 16 is provided with two opposing distribution feed screws 21, and one end of the feed screw 21 is connected to the finite seat 20, the limit seat 20 The working surface is in a circular arc, and the shared spring is mounted with the holding spring 34 with the drill bit 10, and the feed screw 21 is mounted, the feed screw 21 is mount...

Embodiment 2

[0029]In order to facilitate the temperature of the drill in real time, it is convenient for timely driving of the heat transfer medium circulation flow, and the present embodiment is improved on the basis of the first embodiment, and the improvement is: the spiral cooling tube 13 is installed with a temperature sensor for Real-time monitoring of the temperature of the heating medium in the spiral cooling tube 13, facilitating the screw drill to cool to ensure normal operation of the screw drill.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com