Probe and test device

A technology of probes and test sockets, which is applied in the direction of measuring devices, measuring electricity, and measuring electrical variables, etc. It can solve problems such as increasing production costs, affecting the accuracy of information transmission, and unfavorable semiconductor testing, etc., to reduce impedance and shorten signal transmission paths Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

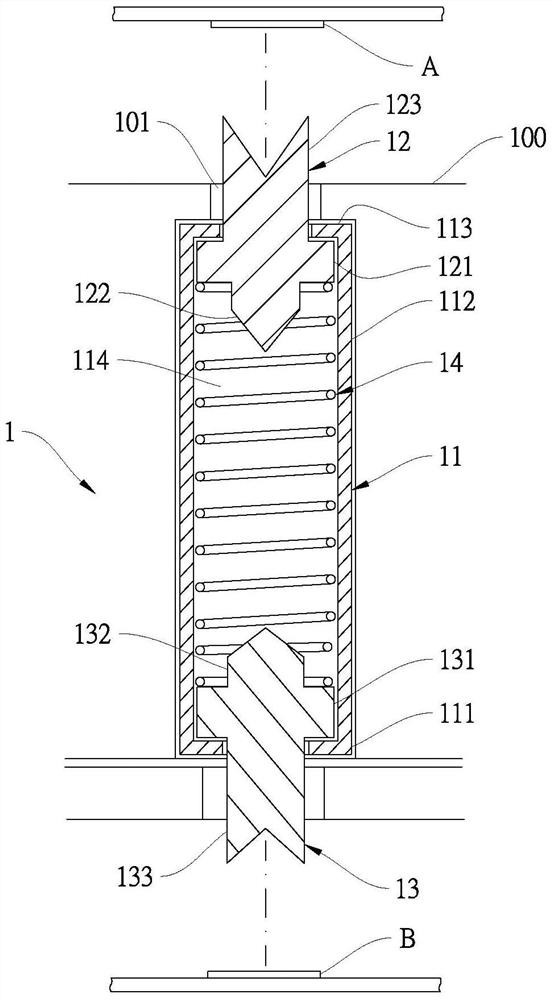

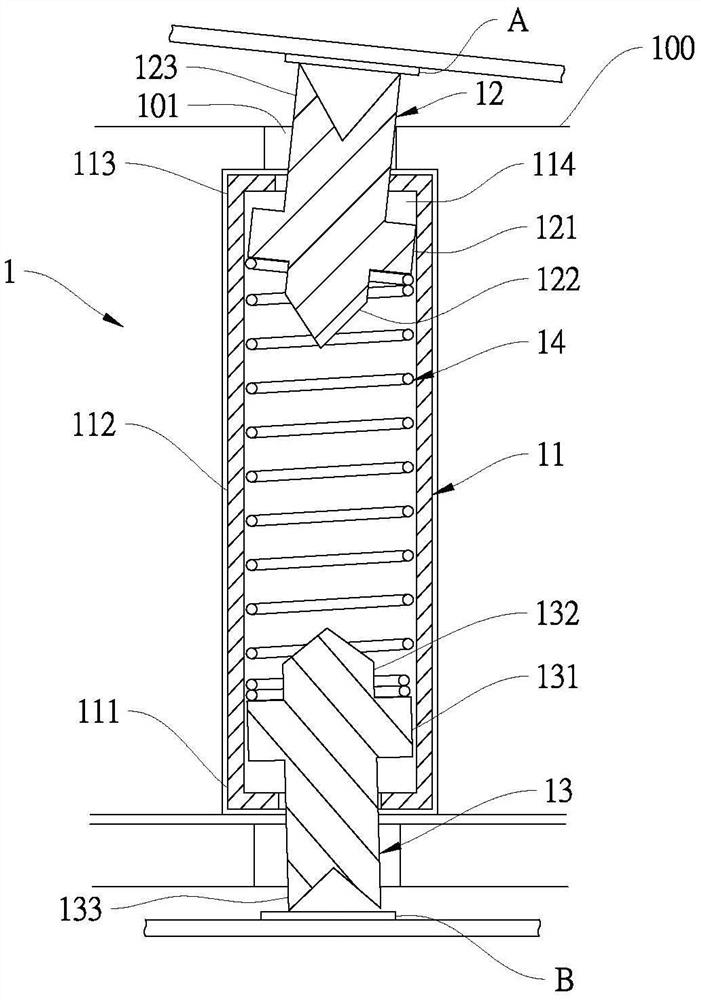

[0026] The features and technical contents of the relevant patent applications of the present invention will be clearly presented in the following detailed description of preferred embodiments with reference to the drawings. Before going into detail, it should be noted that like components are numbered the same.

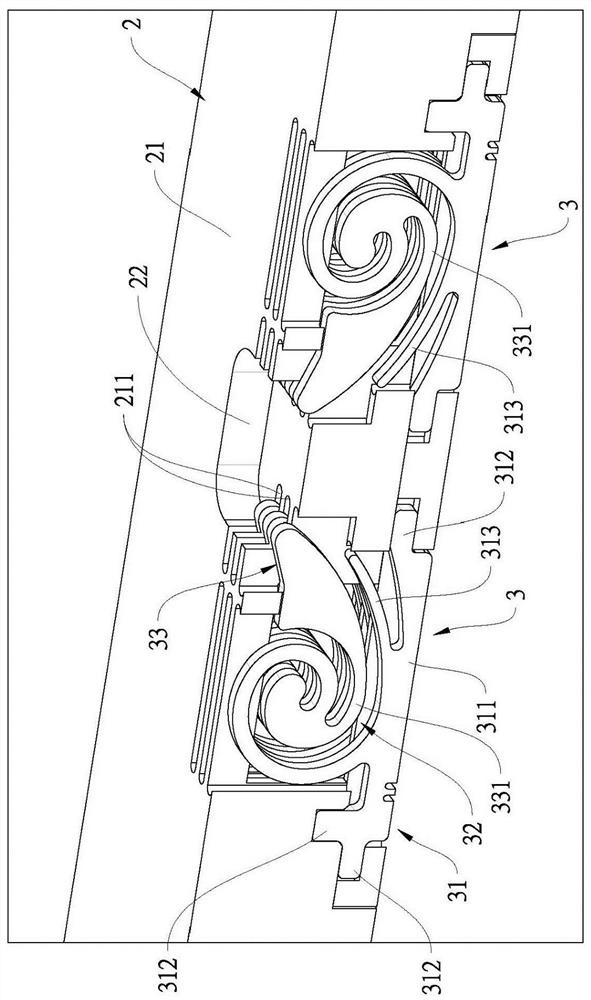

[0027] refer to image 3 Shown, be the preferred embodiment of testing device of the present invention, in order to test a chip 4 (shown in Figure 5 Middle), the test device includes a test seat 2, and several probes 3 arranged in the test seat 2 at intervals.

[0028] The test base 2 includes a base body 21 and a test space 22 formed on the base body 21 . Wherein, the seat body 21 has several installation holes 211 arranged at intervals. In this embodiment, the test space 22 is rectangular, and the several installation holes 211 are spaced along two sides of the test space 22. arrangement. It should be noted that the arrangement of the mounting holes 211 is des...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com