Negative electrode material for secondary battery, negative electrode for secondary battery, and secondary battery

A secondary battery and negative electrode material technology, applied in the direction of secondary batteries, battery electrodes, negative electrodes, etc., can solve problems such as shedding, negative electrode active material rupture, cycle characteristics and initial Coulombic efficiency degradation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

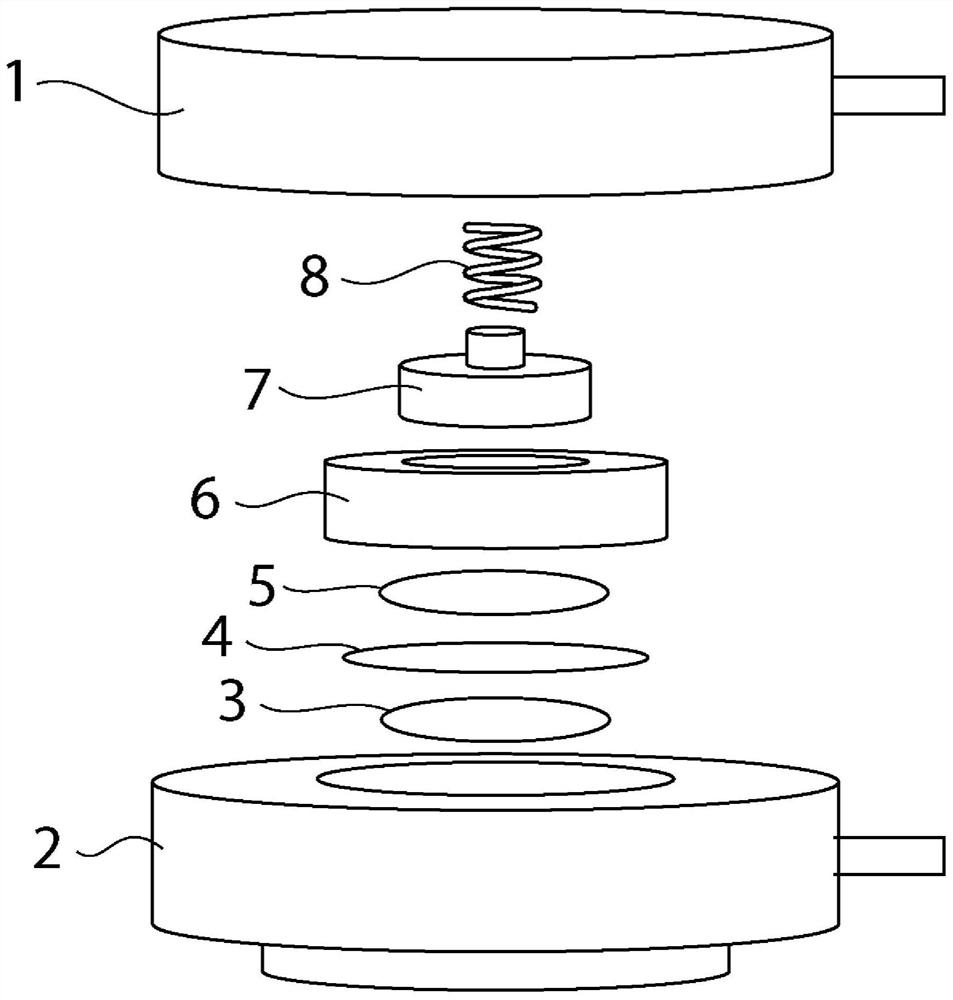

preparation example Construction

[0108] As a preparation method of the negative electrode, for example, a method of forming a mixture of a negative electrode active material, a carbon material, and a binder resin on a current collector is mentioned.

[0109] From the viewpoint of easier production of the negative electrode, the following production method is preferable. First, a binder solution or a dispersion liquid is added to a negative electrode active material containing a metal or a metal compound, a first carbon material, and a second carbon material, and mixed to prepare a slurry. Next, the prepared slurry was coated on a current collector, and finally a negative electrode was prepared by removing the solvent.

[0110] As a preparation method of the said slurry, the method of mixing using a stirrer etc. is mentioned. It does not specifically limit as a stirrer used for mixing, A planetary mixer, a disperser, a thin-film rotary mixer, a jet mixer, an autorotation-revolution mixer, etc. are mentioned. ...

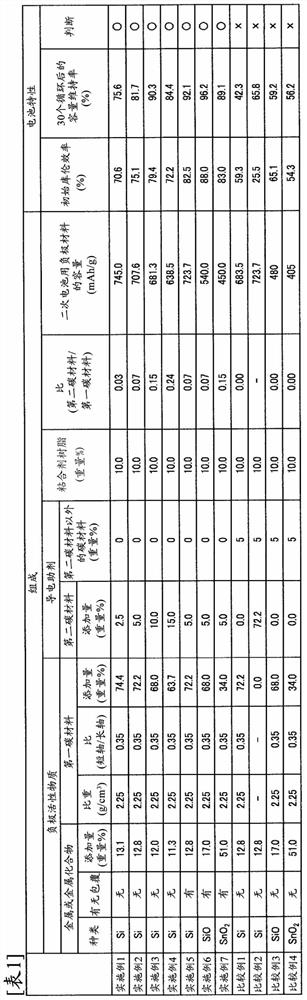

Embodiment 1

[0142] Silicon particles as a metal or a metal compound, graphite particles as a first carbon material, the second carbon material produced in accordance with the above-mentioned production example, and polyamic acid as a precursor of the binder resin were calculated according to the weight ratio (silicon particles: the first One carbon material: second carbon material: polyamic acid)=13.1:74.4:2.5:10.0 were mixed to prepare a mixture. As silicon particles, a product manufactured by ALDRICH Corporation (average particle diameter: <100 nm) was used. As the graphite particles, those manufactured by OSAKA GASCHEMICAL Co., Ltd. under the trade name "OMAC-R" (average particle diameter: 18 μm) were used. In addition, as the polyamic acid, a product made by Ube Industries, Ltd. and a product name "U-VARNISH-A" was used.

[0143] Next, to the obtained 5 g mixture, an appropriate amount of N-methylpyrrolidone (NMP) was added as a solvent, and stirred and mixed using a self-rotating an...

Embodiment 2~4

[0146] Except that the weight ratio of silicon particles (Si, metal or metal compound), first carbon material, second carbon material, and polyamic acid (adhesive resin precursor) is changed according to the following Table 1, it is the same as Example 1 , to obtain the negative electrode sheet.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com