Foreign matter removing system for power equipment maintenance

A technology for power equipment and foreign matter, applied in the field of foreign matter removal system, can solve the problems of difficult foreign matter picking up, staff scratches, etc., and achieve the effect of improving safety and improving removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

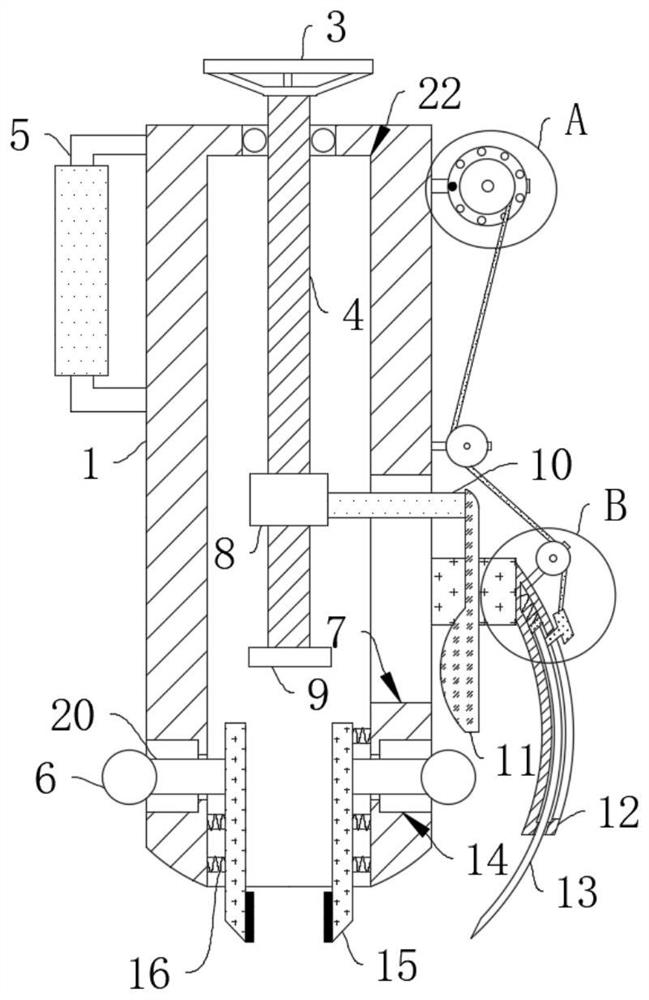

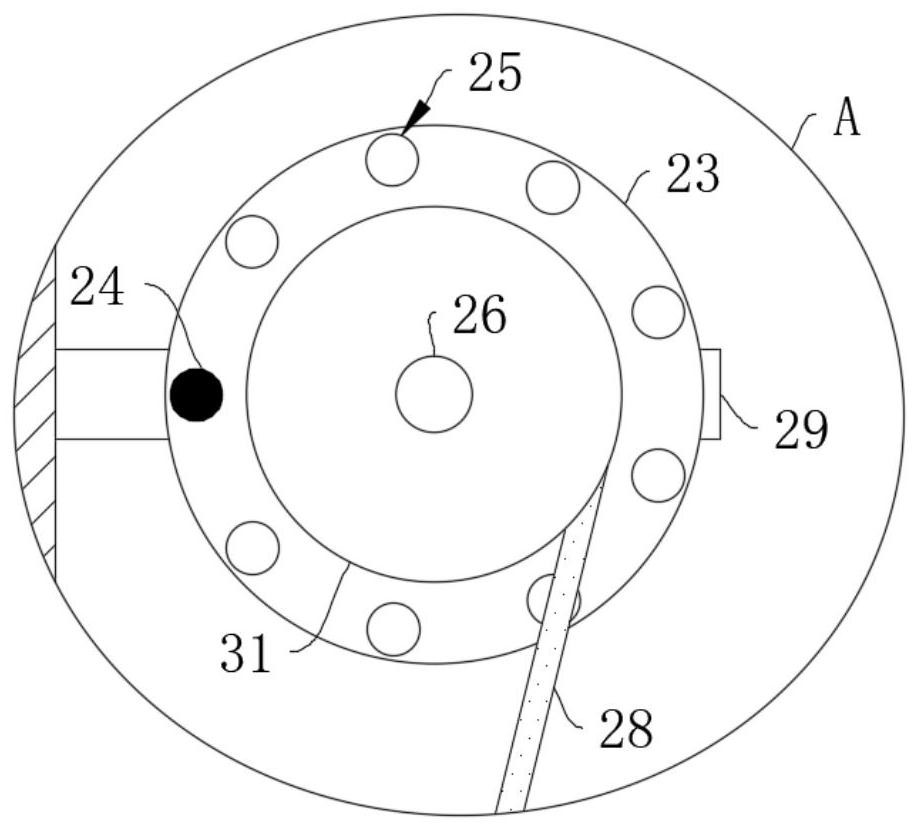

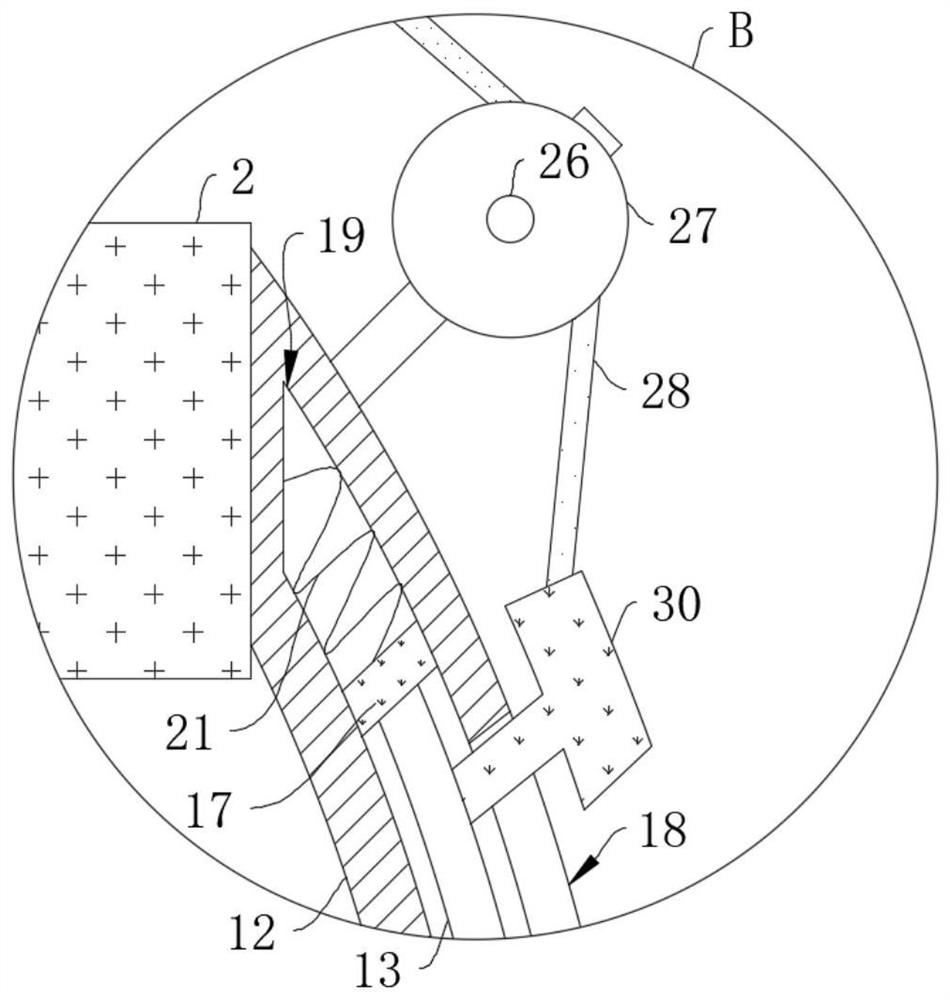

[0025] refer to Figure 1-3 , a foreign matter removal system for power equipment maintenance, including a fixed frame 1, a straight groove 22 is opened in the fixed frame 1, a threaded rod 4, a threaded sleeve 8 and a limit block 9 are arranged in the straight groove 22, and the threaded rod 4 Rotationally connected on the fixed frame 1, the threaded rod 4 is threadedly connected with the threaded sleeve 8, and the thread rise angle of the threaded rod 4 is smaller than the friction angle between the threaded rod 4 and the threaded sleeve 8, so the threaded rod 4 and the threaded sleeve 8 can be Self-locking, the top of the threaded rod 4 runs through the fixed fram...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap