Cluster electrode electrosparking device

A processing device and electric spark technology, applied in electric processing equipment, accessories, metal processing equipment, etc., can solve the problems of inconvenient adjustment and inconvenient operation, and achieve the effect of meeting the requirements of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings.

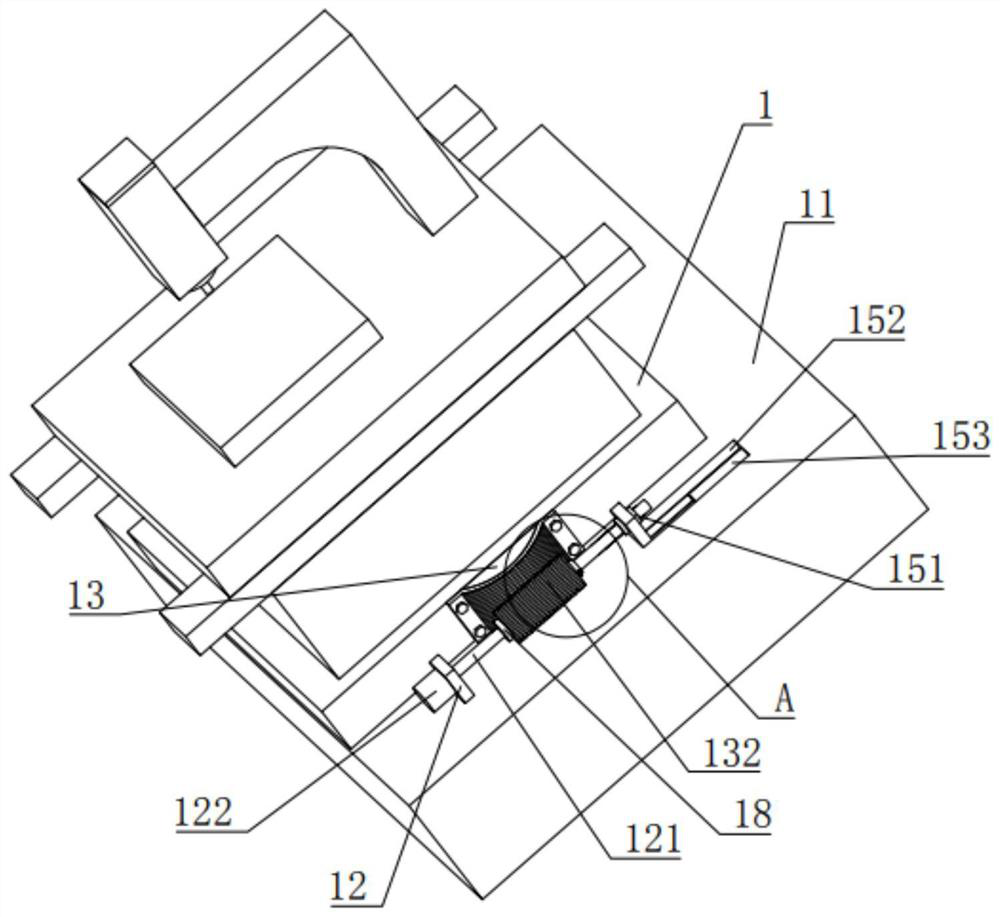

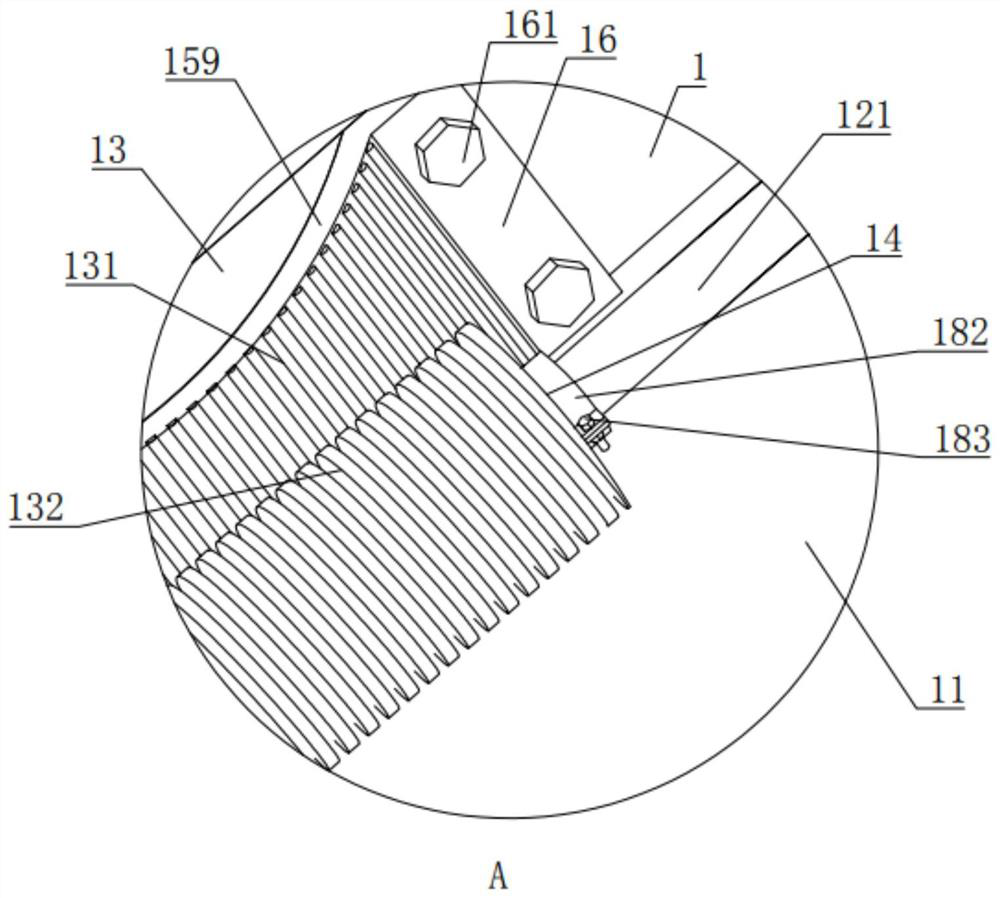

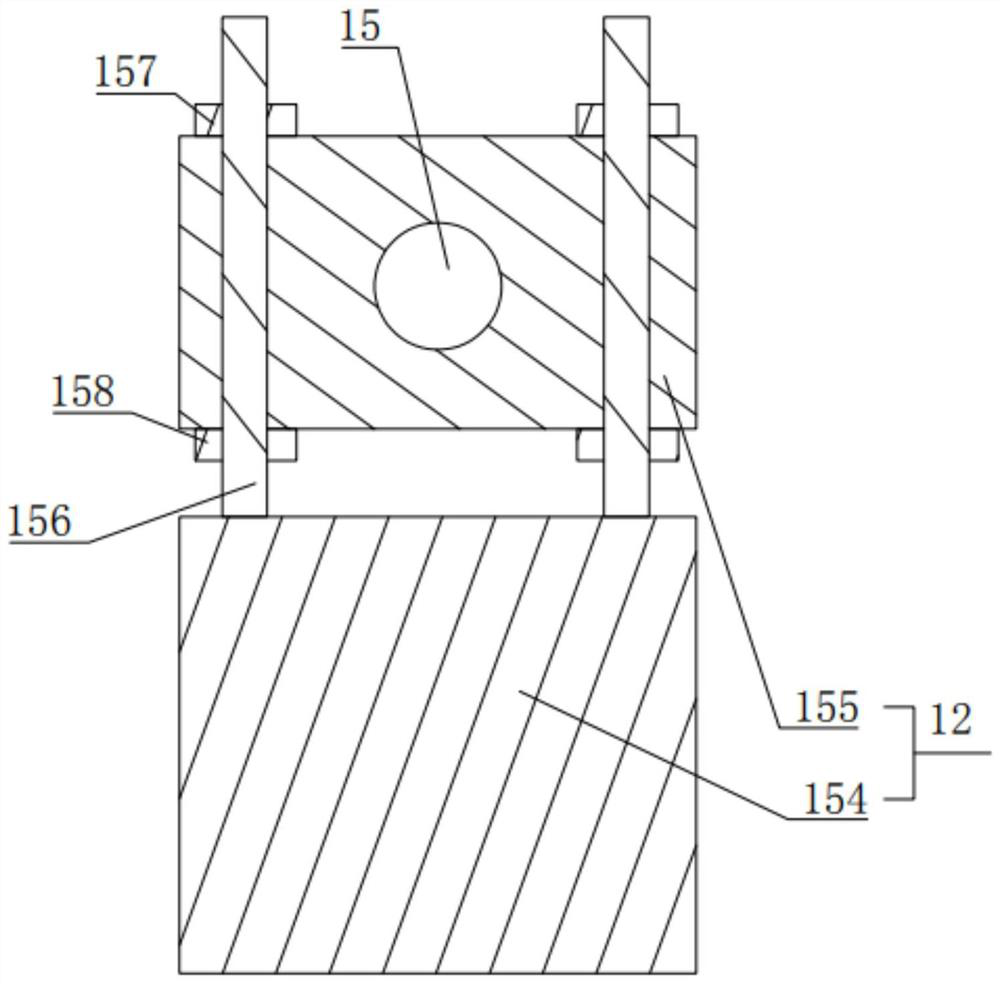

[0027] A cluster electrode electric discharge machining device, such as figure 1 and figure 2 , including a base 1, a support block 11 arranged at the lower end of the base 1 and placed on the ground, the base 1 is rotatably connected to the support block 11, the base 1 can be rotatably connected to the support block 11 through a central axis, and the central axis is set on the base 1 Above, the supporting block 11 is provided with a driving member for driving the base 1 to rotate. The electric discharge machining device is arranged on the base 1. Since the electric discharge machining device is a prior art and will not be described here, the support block 11 is flush with the side of the base 1 on the side operated by the user, which is convenient for the operator to operate.

[0028] Such as figure 1 and figure 2 , when the position of the base 1 need...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com