Blade surface smoothing and cleaning equipment of hydroelectric generator

A generator blade and smooth surface technology, which is applied in the direction of grinding/polishing equipment, metal processing equipment, grinding machine tool parts, etc., can solve the problems of difficult operation, difficult manual grinding, poor grinding effect, etc., and achieve improved firmness performance, improved practicability and reliability, and the effect of improving practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

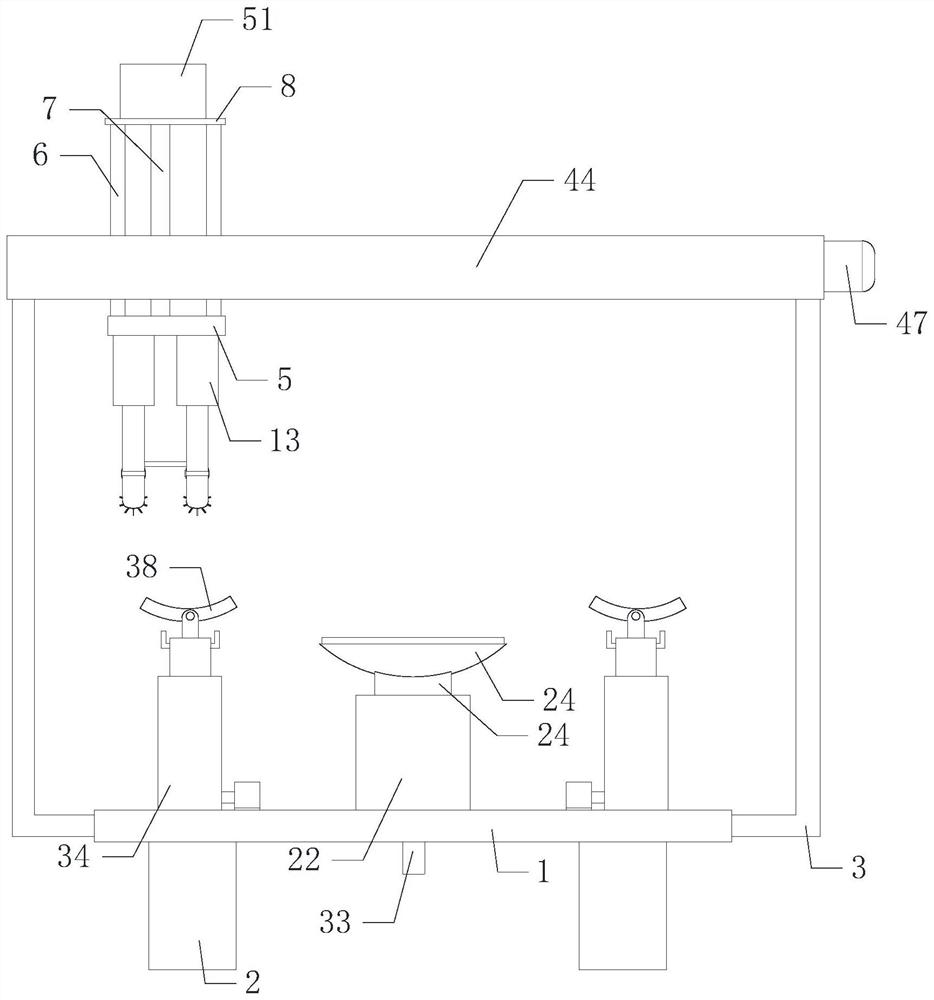

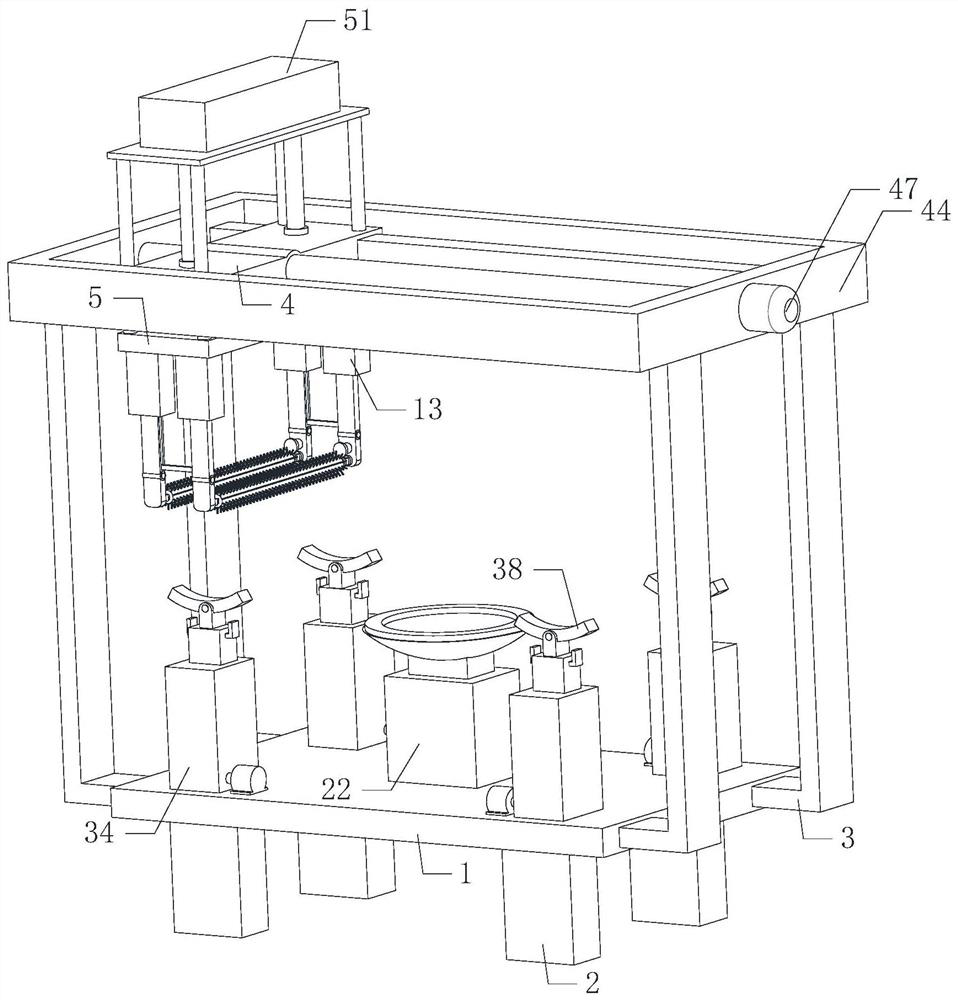

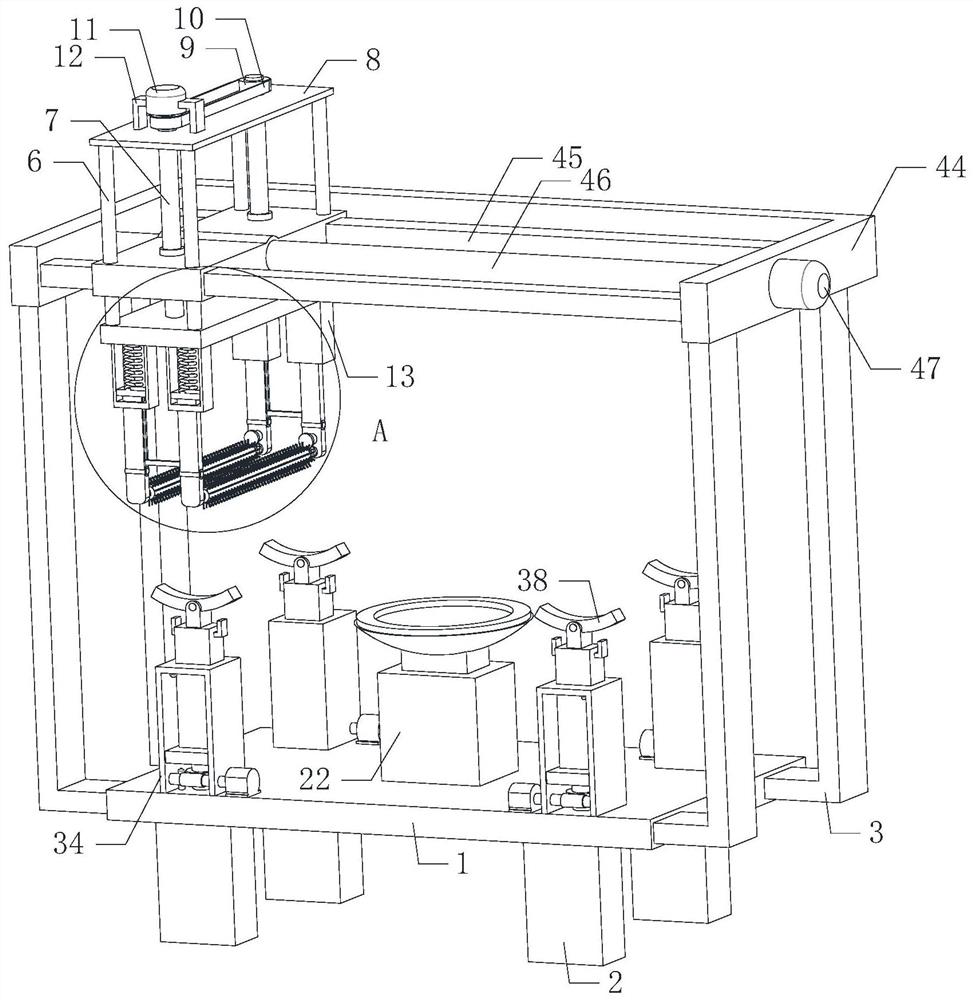

[0021] Such as Figure 1 to Figure 6 As shown, the surface smooth cleaning equipment of the hydraulic generator blade of the present invention, when it is working, the blade of the hydraulic generator is placed on the fixing device, and the fixing device fixes it, and the tops of the four groups of lifting devices are all connected to the bottom of the blade. Outer contact, four sets of lifting devices can lift the blades, thereby preventing the blades from moving randomly, the fixed direction of the blades corresponds to the direction of the two sets of brush rollers 19, and the two sets of second motors 20 are turned on, and the two sets of second motors 20 pass through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com