Routing method for robot rotational joint assembly

A technology of rotating joints and rotating components, applied in the field of robots, can solve problems such as unreliability, long production cycle, looseness, etc., and achieve the effect of reducing frictional contact and cable wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

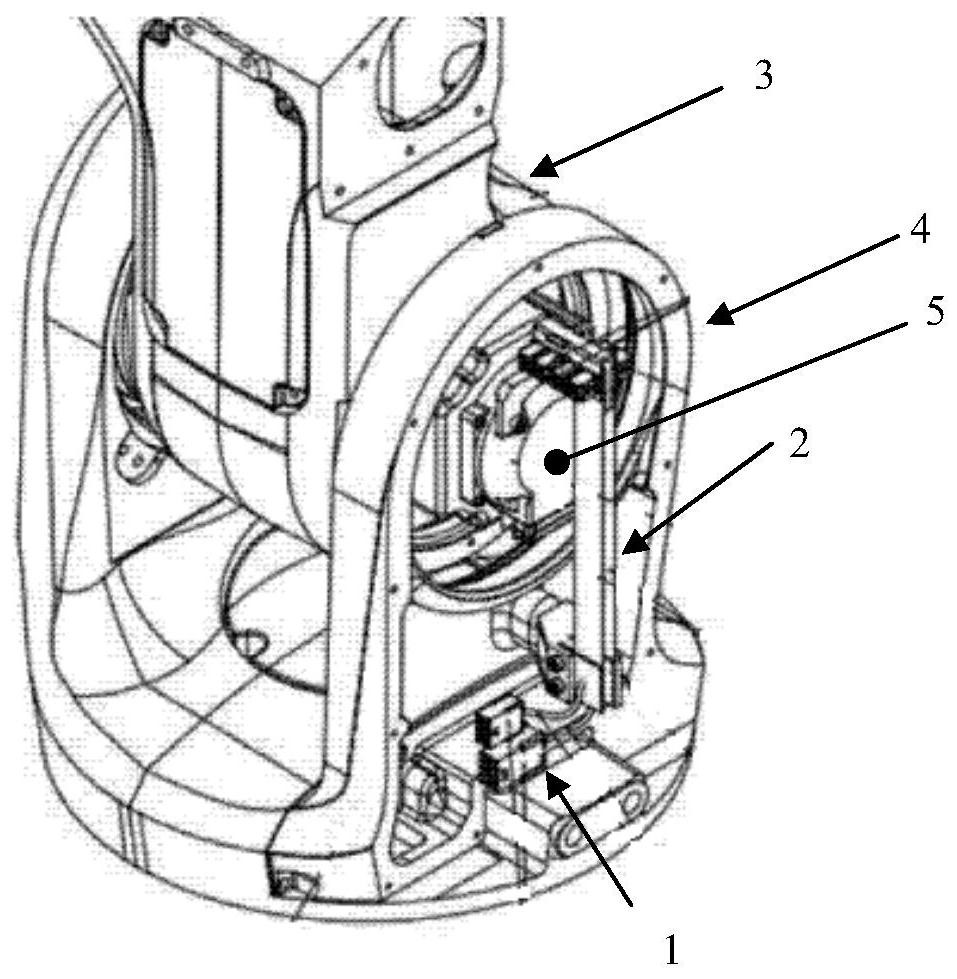

[0035] Please refer to figure 2 and image 3 , the present invention provides a multi-joint industrial robot using ordinary cables as power lines and control lines, including a base 10 arranged on the workbench (not shown in the figure), installed on the base 10 and winding perpendicular to the The swivel joint mount 20 that rotates on the axis of the workbench top, the first swivel joint 30 that is hinged to the swivel joint mount 20 and rotates around an axis parallel to the workbench top, is hinged on the first swivel joint 30 is away from one end of the swivel joint mounting seat 20 and rotates on an axis parallel to the first swivel joint 30. The second swivel joint 40 is installed on the second swivel joint 40 and rotates around the workbench surface. The connecting arm 50 , which is parallel to and rotates on an axis perpendicular to the rotation axis of the second rotating joint 40 , is installed on the side of the connecting arm 50 away from the second rotating join...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com