Code scanning type numerical control sawing system and machining method thereof

A sawing and code scanning technology, which is applied in the direction of transmission system, sawing components, sawing equipment, etc., can solve the problem that it is difficult for the internal staff of the company to understand the real-time situation of the sheet in real time, the control parameters need manual input, and the degree of intelligence Low-level problems, to achieve the effect of facilitating daily processing, avoiding manual input, and high degree of intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

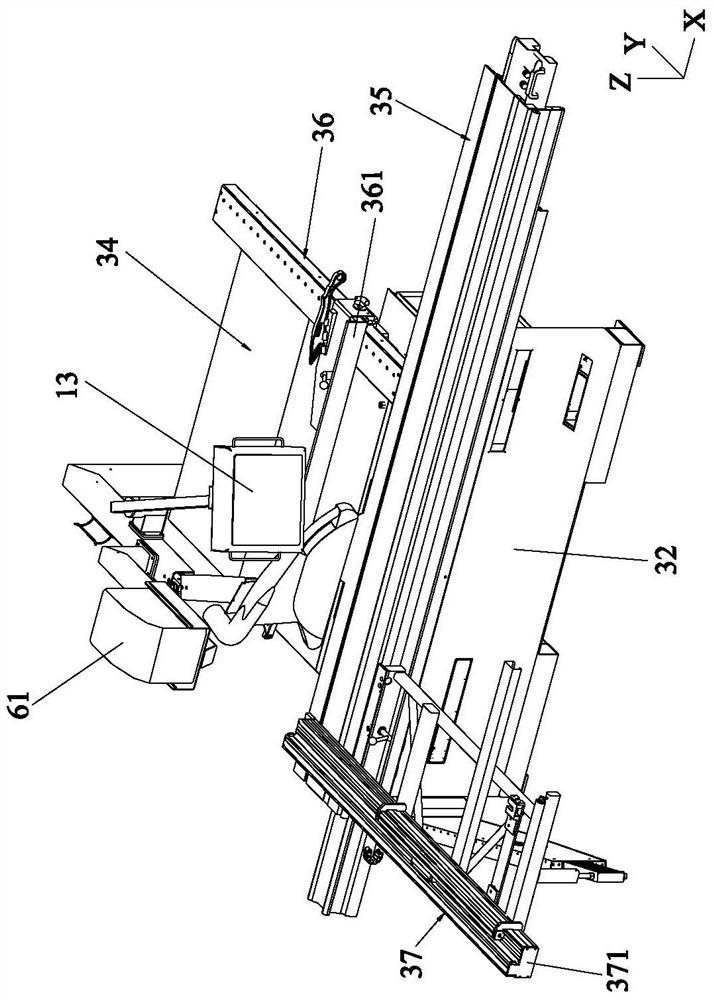

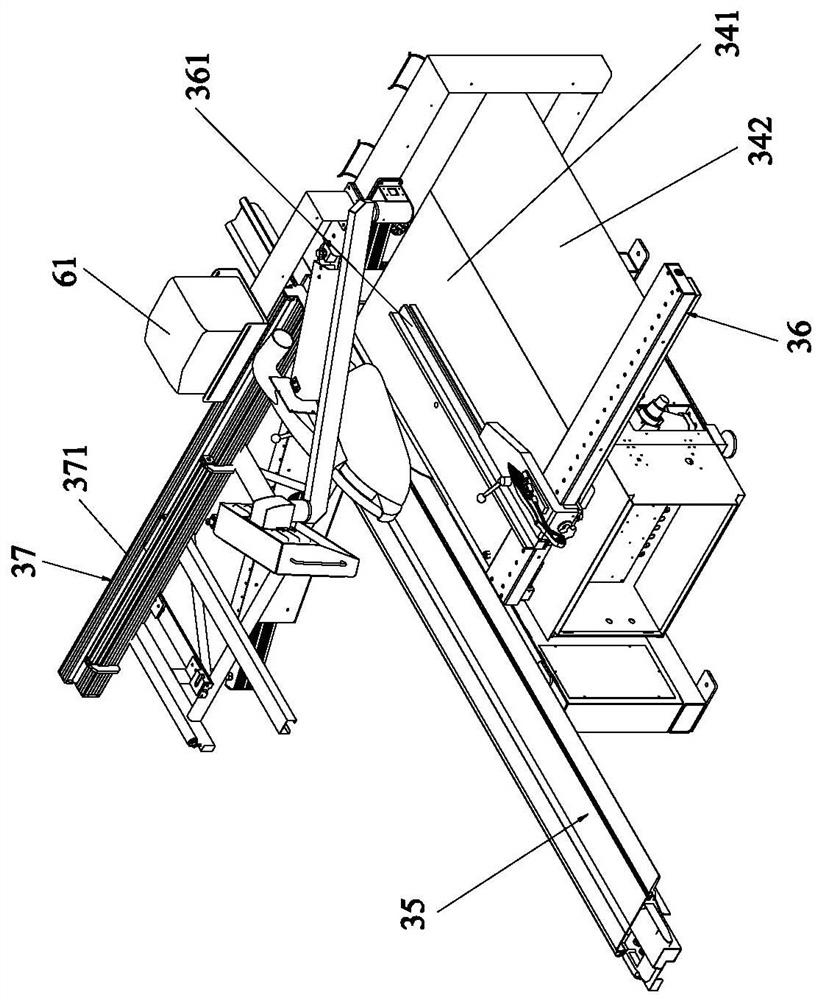

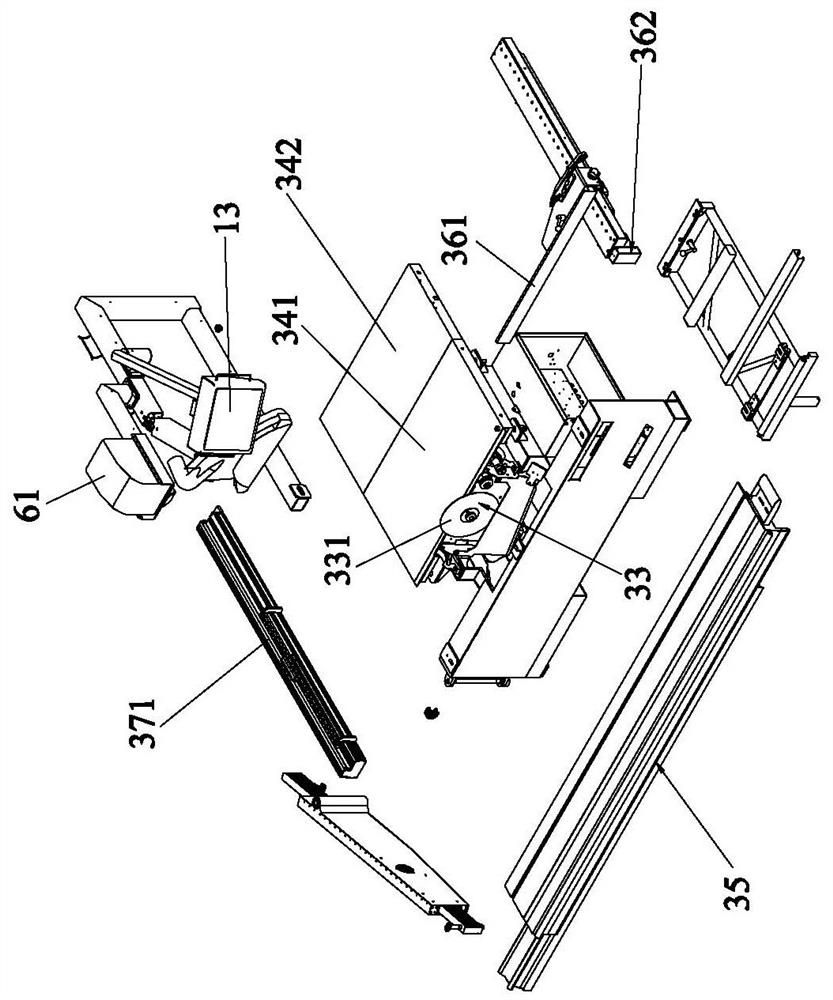

[0072] Such as Figure 1 to Figure 4 As shown, a code-scanning CNC sawing system includes an industrial computer 10 with a display screen 13, a PLC 20, a table saw, a first switch 41, a second switch 42, a database 43, a handheld unit 50, and a bar code and connected to the printer 61 of the industrial computer 10, the scanning gun 63 for scanning the two-dimensional code on the plate to be processed, and at least one PC 62;

[0073] The display screen 13 is a touch screen. The industrial computer 10 is communicated with the first switch 41 through Ethernet, and the first switch 41 is respectively connected to the PLC 20 and the second switch 42 through the Ethernet, and the second switch 42 is a LAN switch. Switch 42 connects PC 62 through Ethernet;

[0074] The sliding table saw includes a CNC controller 31, a frame 32 and a sawing device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com