Improved type edge sealing machine for door plate production

An edge banding machine, an improved technology, applied in the direction of conveyors, household components, conveyor objects, etc., can solve problems such as inconvenient and inability to achieve continuous processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

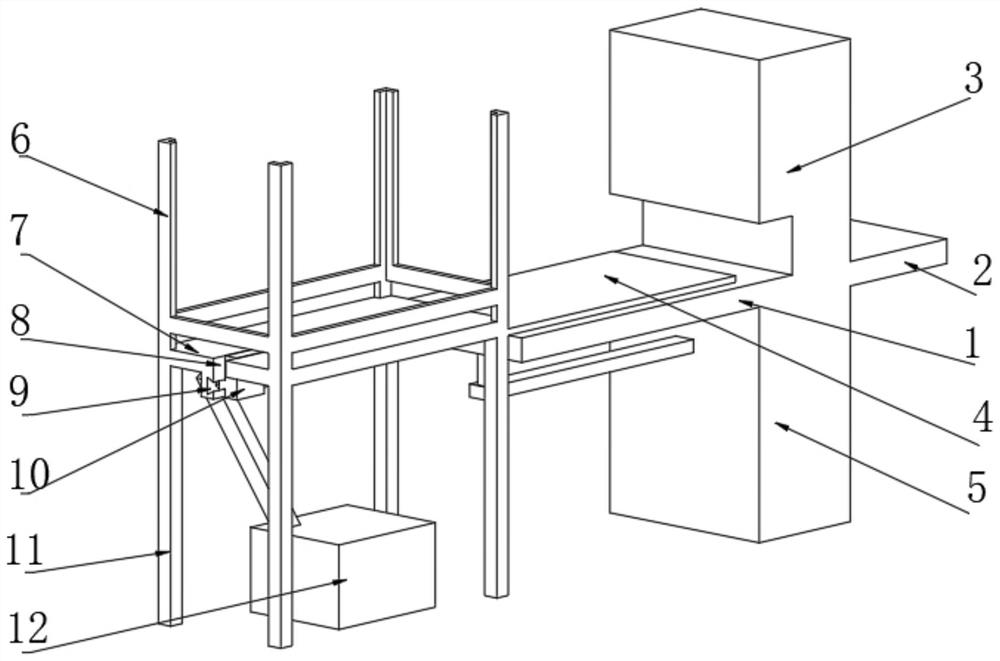

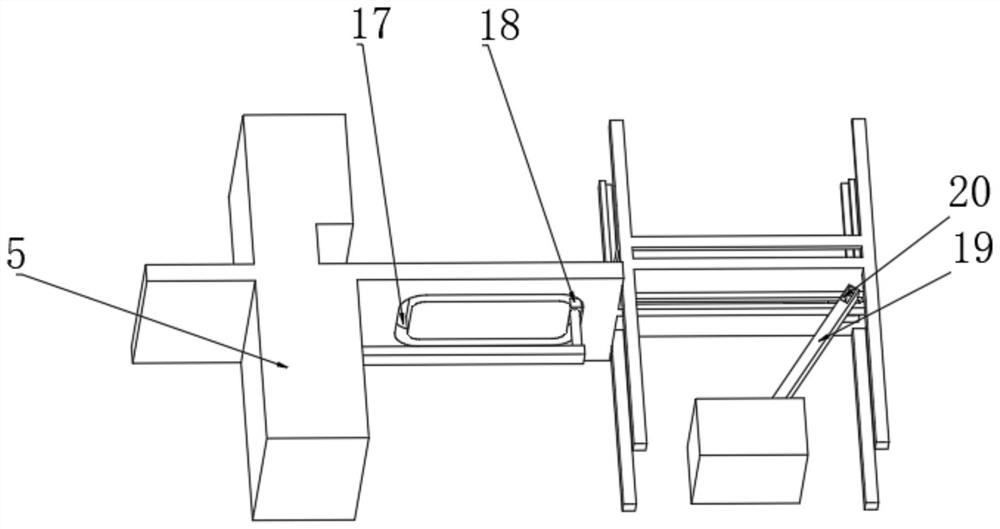

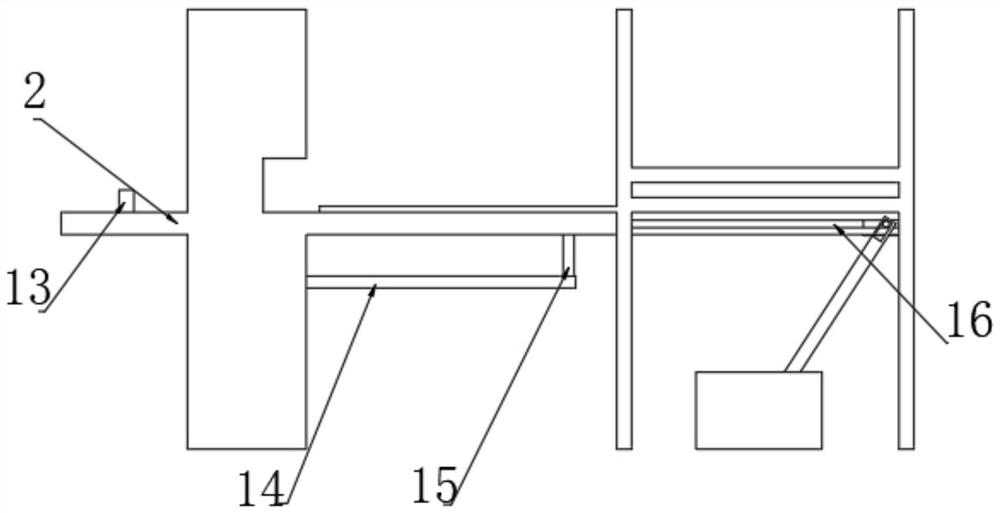

[0028] Such as Figure 1-7 As shown, an improved edge banding machine for door panel production includes a rotary table 1, the lower end of the right side of the rotary table 1 is integrally connected with a rotary structure 5, and the right end of the rotary structure 5 is integrally connected with the edge banding raw material The fixed plate 2, and the upper surface of the edge-banding raw material fixing plate 2 is rotatably equipped with an edge-banding raw material fixing column 13 perpendicular to it, and the upper end of the right side of the rotary table 1 is integrally connected with an edge-banding device 3, and the rotary working A rotating plate 4 is installed on the upper surface of the table 1. The left end of the rotating table 1 is integrally connected with a feeding plate 7. The upper surface of the feeding plate 7 is integrally connected with four door panel fixing frames 6 to be processed vertically upwards. The lower surface of the feeding plate 7 is integ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com