Umbrella-shaped roller cam rotating table

A roller cam, rotary table technology, applied in belt/chain/gear, transmission, mechanical equipment, etc., can solve the problems of difficult cam tooth surface processing, stress concentration, excessive wrap angle, etc., and achieve good economic benefits and social benefits, meet the requirements of machining accuracy, and increase the effect of structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1. The vertical cylinder of the present invention is in front of the horizontal cylinder:

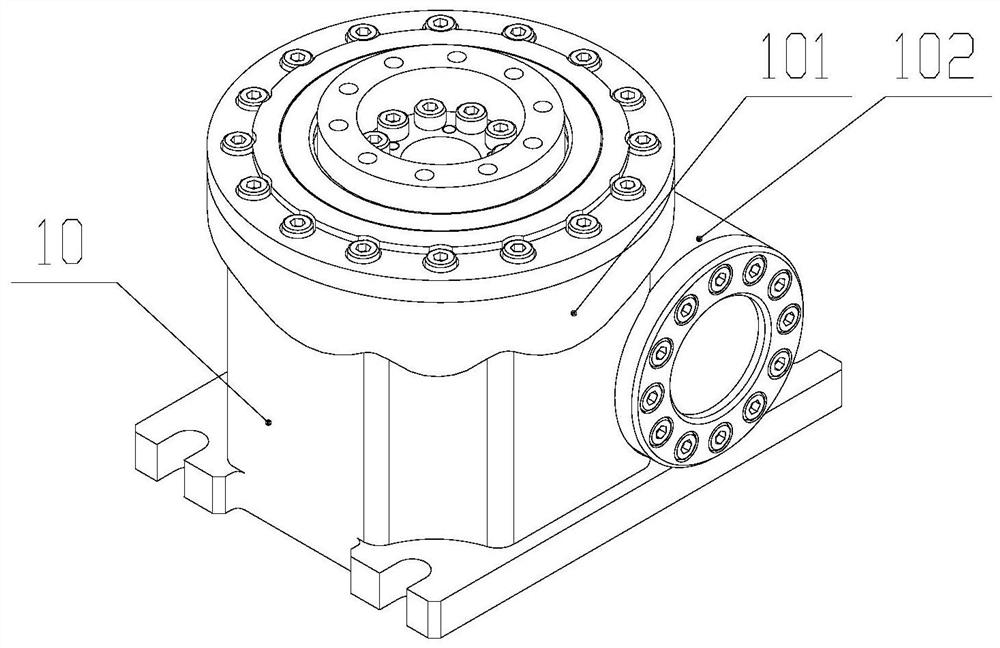

[0038] Such as figure 1 As shown, the present invention provides an umbrella-type roller cam rotary table, which is composed of a cabinet 10, a turret mechanism and a cam mechanism. The bottom plate of the ring is formed, the axis of the vertical cylinder 101 is perpendicular to the axis of the horizontal cylinder 102; the vertical cylinder 101 and the horizontal cylinder 102 interpenetrate;

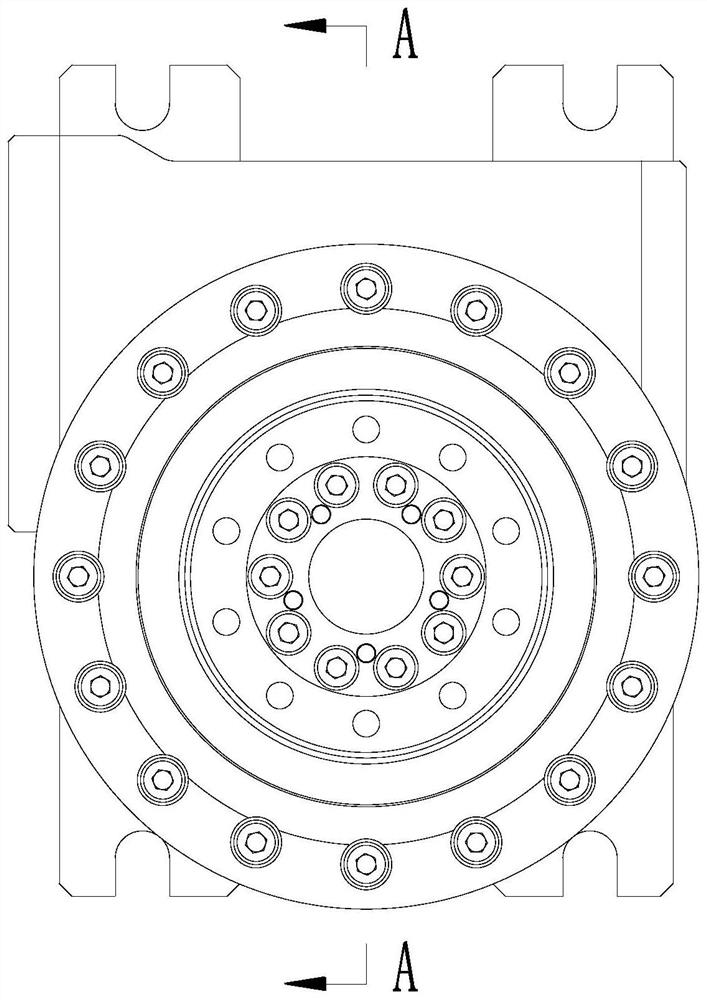

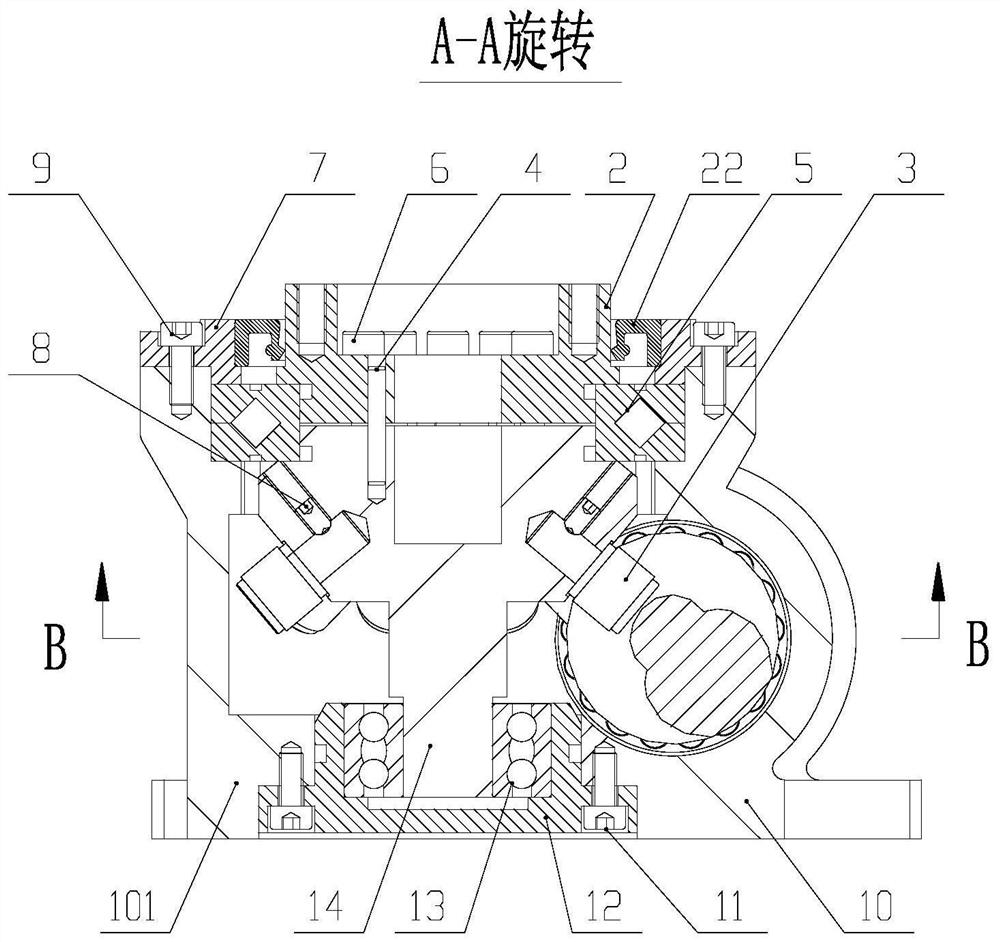

[0039] Such as figure 2 , image 3 As shown, a turret mechanism is arranged in the vertical cylinder body 101, and the turret mechanism is arranged along the axis of the vertical cylinder body 101. The turret mechanism is sequentially provided with a turntable 2, a turret 14, and a second seat plate 12 from top to bottom. Wherein the outer ring of the turntable 2 is provided with first seat plates 7 arranged at intervals; the turntable 2 is fixed on the top of the turret 14 b...

Embodiment 2

[0058] Embodiment 2, the vertical cylinder of the present invention is behind the horizontal cylinder:

[0059] Such as Figure 5 , Figure 6 As shown, a turret mechanism is arranged in the vertical cylinder body 101, and the turret mechanism is arranged along the axis of the vertical cylinder body 101. The turret mechanism is sequentially provided with a turntable 2, a turret 14, and a second seat plate 12 from top to bottom. Wherein the outer ring of the turntable 2 is provided with first seat plates 7 arranged at intervals; the turntable 2 is fixed on the top of the turret 14 by at least one cylindrical pin 4 and several first screws 6 evenly distributed around the circumference;

[0060] The turret 14 is provided with a circular platform with a large upper part and a smaller one. Several rollers 3 are distributed on the side of the circular platform of the turret 14 in an umbrella shape. Several rollers 3 are evenly distributed around the circumference along the side of t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap