Energy utilization method in calcium carbide production process

A production process, calcium carbide technology, applied in the direction of calcium carbide, carbide, processing and discharging materials, etc., can solve the problem of poor continuity of calcium carbide products, poor continuity of calcium carbide products, difficult to solve wall adhesion, difficult heat utilization, etc. problems, to achieve the effect of reducing manual operation links, convenient implementation and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

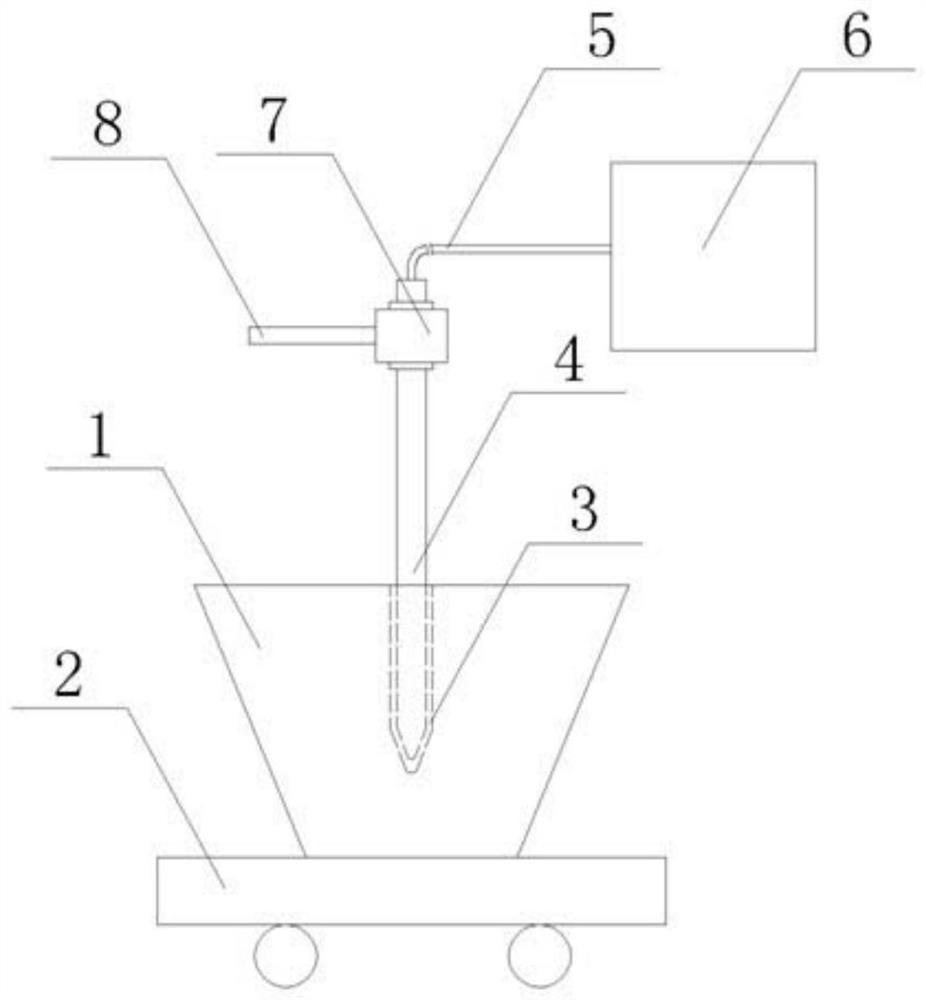

[0017] specific embodiment figure 1 As shown, including crucible 1, transport vehicle 2, pre-drilled hole 3, superconducting circuit 4, flexible superconducting pipe 5, heating equipment 6, mechanical fixture 7, and robotic arm 8, crucible 1 is arranged on the transport vehicle 2, pre-drilled The hole 3 is located in the middle of the crucible 1, one end of the superconducting pipe 4 is arranged in the pre-drilled hole 3, the other end of the superconducting pipe 4 is connected with one end of the flexible superconducting pipe 5, and the other end of the flexible superconducting pipe 5 is connected with the heating The equipment is connected, and the upper end of the super catheter 4 is fixed by a mechanical clamp 7 and a mechanical arm 8 .

[0018] The single 40.5MVA closed calcium carbide production furnace aimed at in this example has an hourly output of 10.67t / h of calcium carbide. The heat per ton of calcium carbide is 790.8kWh / t. Each shift is released according to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com