A Trajectory Accuracy Analysis Method for Industrial Robots Based on Continuous Dynamic Time Warping

A dynamic time-warping, industrial robot technology, applied in manipulators, manufacturing tools, program-controlled manipulators, etc., to avoid mapping errors and improve trajectory accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

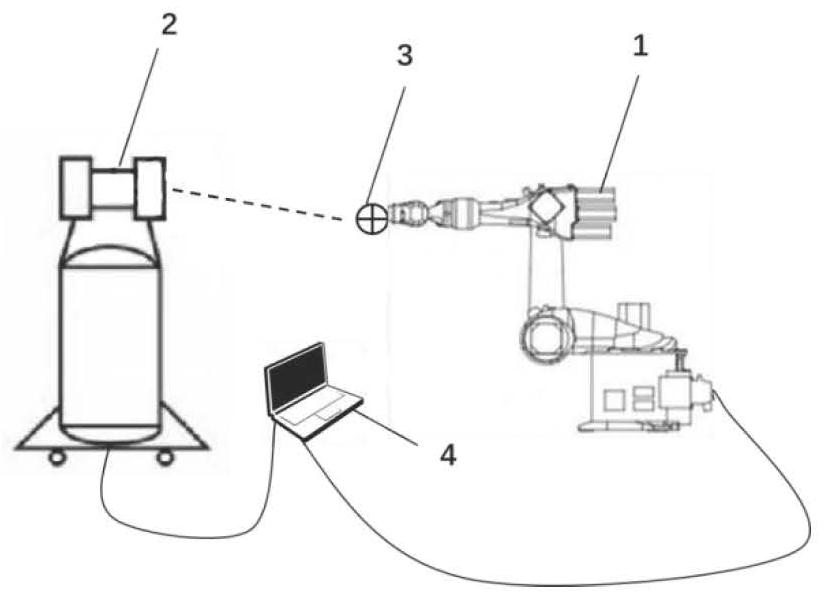

[0034] A laser tracker is used to measure the trajectory of an industrial robot, and the measurement system such as figure 1 shown. The system includes 1-industrial robot, 2-laser tracker, 3-target ball, 4-host computer.

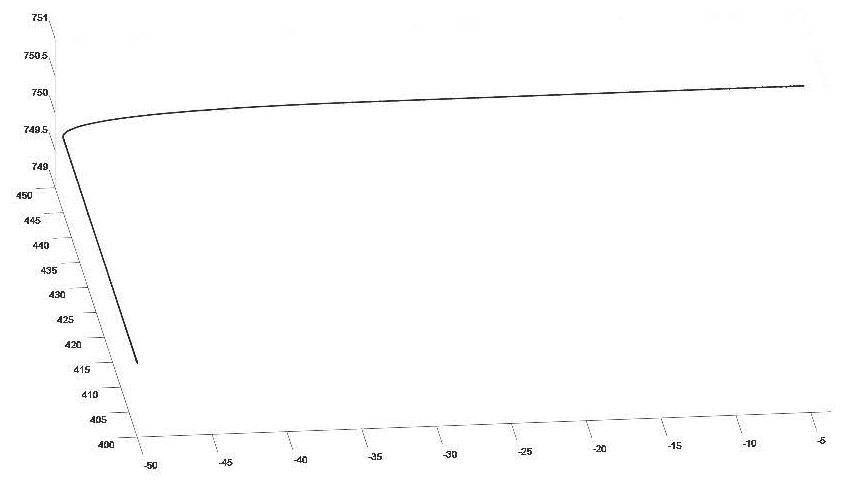

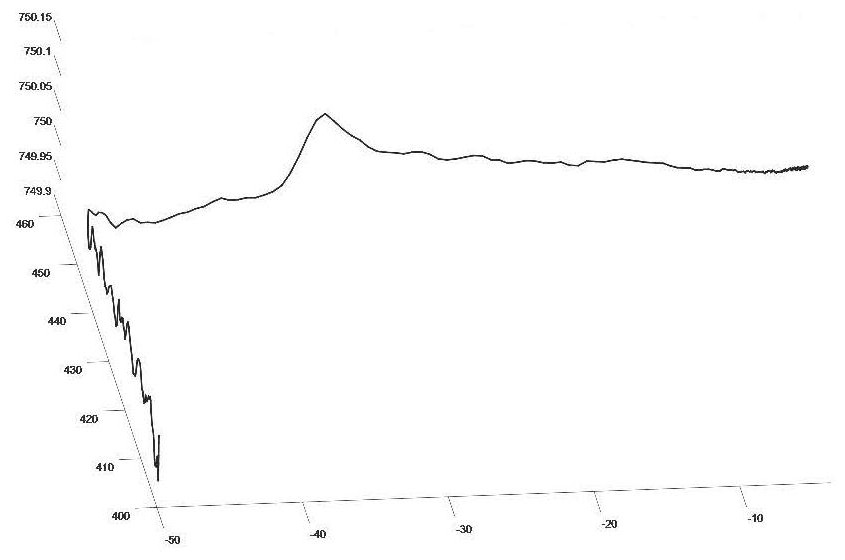

[0035] Compile a test trajectory based on the optional test trajectory data set specified in the ISO standard, which is located in the standard test plane within the working space range of the industrial robot, including a combination of straight line, circular arc and corner motion. The robot first executes a straight line trajectory, the coordinates of the starting point P1 are (400,-50,750), and the coordinates of the arrival point P2 are (450,-50,750). Next, perform a smooth corner of the arc type, and set the corner to 5mm. Finally, a straight line trajectory is executed, and the end point P3 is (450,0,750).

[0036]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com