Sole nano anti-skid layer and preparation method thereof

A kind of anti-skid layer, nano technology, applied in the direction of soles, footwear, clothing, etc., can solve the problems of rapid wear of soles, decline in anti-skid performance, etc., to increase the roughness, increase the interaction force, and improve the effect of compatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

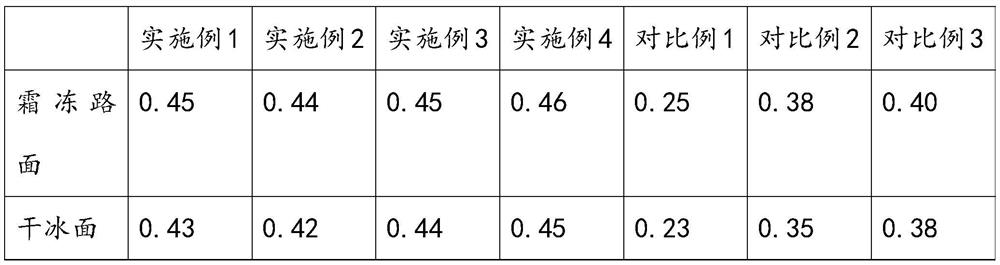

Examples

Embodiment 1

[0027] A nano anti-slip layer for soles, comprising the following raw materials in parts by weight: 50 parts of anti-skid rubber, 15 parts of composite polyethylene, 10 parts of glass fiber, 3 parts of nylon fiber, 1 part of stearic acid, 1 part of antioxidant 1010, 0.5 part of micro crystal wax;

[0028] The nano anti-slip layer of the sole is made by the following method:

[0029] Add non-slip rubber, composite polyethylene, glass fiber, nylon fiber, stearic acid, antioxidant 1010 and microcrystalline wax into the internal mixer and mix in sequence. The mixing time is controlled to be 5 minutes, and the mixing temperature is 110°C to prepare the mixture , and then the mixture is pressed into tablets by an open mill, and then punched by a cutting machine to obtain a rubber material, and then the rubber material is transferred to a mold for vulcanization. The vulcanization temperature is controlled at 150°C, and the molding time is 300s to obtain nano anti-slip. layer.

[00...

Embodiment 2

[0037] A nano anti-slip layer for soles, comprising the following raw materials in parts by weight: 55 parts of anti-skid rubber, 18 parts of composite polyethylene, 12 parts of glass fiber, 4 parts of nylon fiber, 1.2 parts of stearic acid, 1 part of antioxidant 1010, 0.6 part of micro crystal wax;

[0038] The nano anti-slip layer of the sole is made by the following method:

[0039] Add non-slip rubber, composite polyethylene, glass fiber, nylon fiber, stearic acid, antioxidant 1010 and microcrystalline wax into the internal mixer and mix in sequence. The mixing time is controlled to be 5 minutes, and the mixing temperature is 110°C to prepare the mixture , and then the mixture is pressed into tablets by an open mill, and then punched by a cutting machine to obtain a rubber material, and then the rubber material is transferred to a mold for vulcanization. The vulcanization temperature is controlled at 150°C, and the molding time is 300s to obtain nano anti-slip. layer.

...

Embodiment 3

[0047] A nano anti-slip layer for soles, comprising the following parts by weight of raw materials: 60 parts of anti-slip rubber, 20 parts of composite polyethylene, 14 parts of glass fibers, 4 parts of nylon fibers, 1.4 parts of stearic acid, 1.2 parts of antioxidant 1010, 0.6 parts of micro crystal wax;

[0048] The nano anti-slip layer of the sole is made by the following method:

[0049] Add non-slip rubber, composite polyethylene, glass fiber, nylon fiber, stearic acid, antioxidant 1010 and microcrystalline wax into the internal mixer and mix in sequence. The mixing time is controlled to be 5 minutes, and the mixing temperature is 110°C to prepare the mixture , and then the mixture is pressed into tablets by an open mill, and then punched by a cutting machine to obtain a rubber material, and then the rubber material is transferred to a mold for vulcanization. The vulcanization temperature is controlled at 150°C, and the molding time is 300s to obtain nano anti-slip. laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com