Strobe Step Lighting Defect Inspection System

A defect detection and step-by-step technology, which is applied in the direction of optical test defects/defects, measuring devices, instruments, etc., can solve problems such as limited, increased system cost and complexity, and few applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

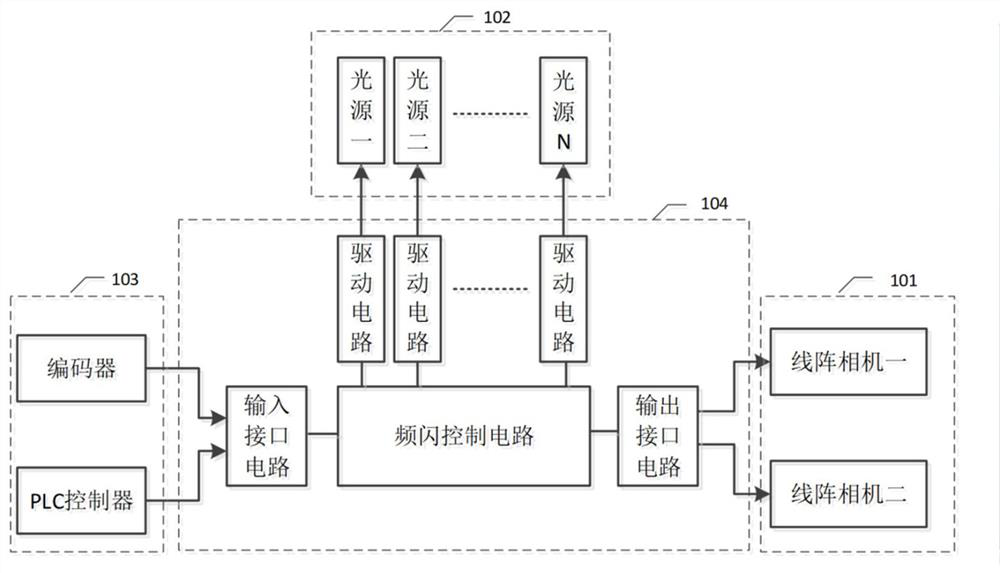

[0130] Such as figure 1 The above is a block diagram of the defect detection system for stroboscopic ladder lighting according to the embodiment of the present invention. Wherein, the defect detection system includes: an image extraction unit (101), a light and shade adjustment unit (102), a data processing unit (103) and a strobe control unit (104). The image extraction unit (101) has a plurality of cameras; the light and shade adjustment unit (102) further includes a plurality of light sources. The data processing unit (103) further includes an encoder and a PLC controller; the strobe control unit (104) further includes: a strobe control circuit, a drive circuit, an input interface circuit and an output interface circuit. The encoder generates a corresponding pulse code signal according to the speed of the mechanical rotation system; the PLC controller is a programmable controller, which generates an enabling signal to the strobe control unit after detecting the object to b...

Embodiment 2

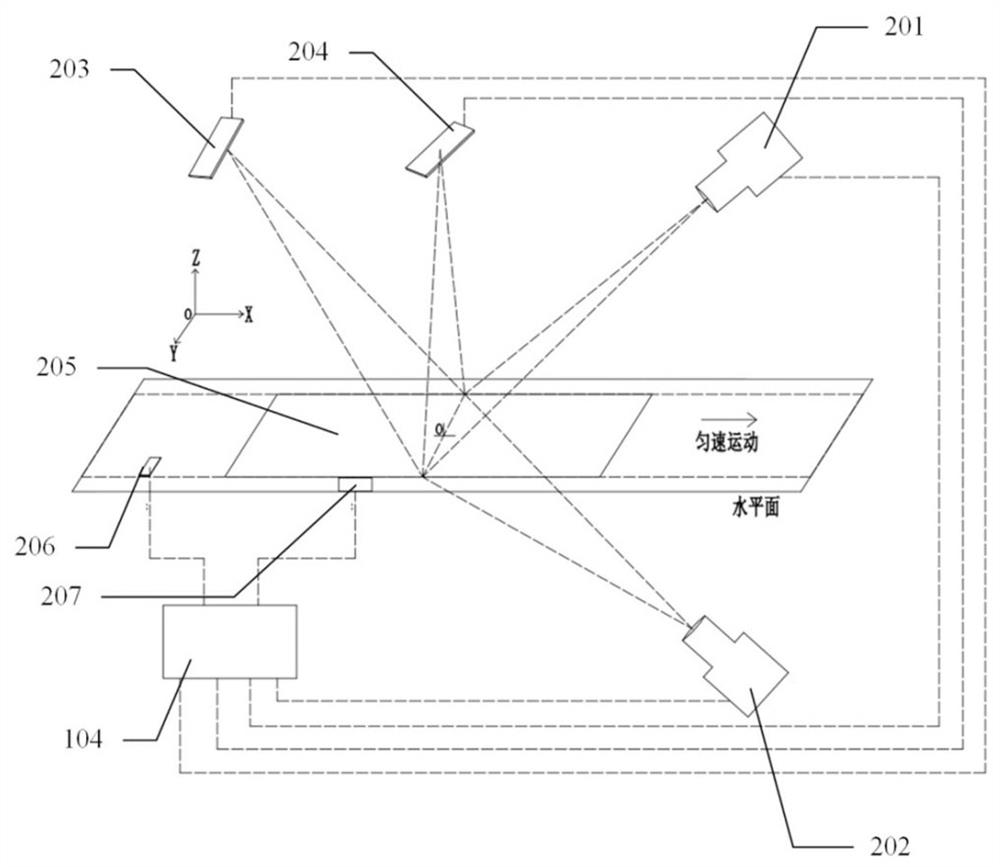

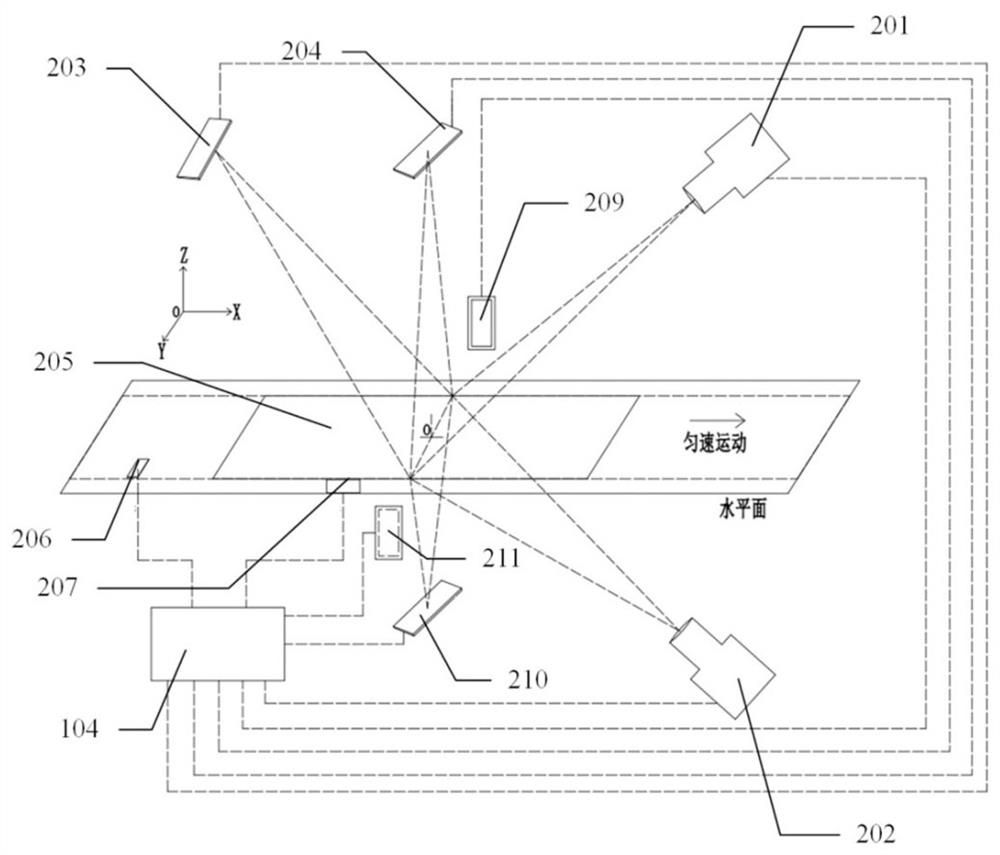

[0156] Such as image 3 As shown, it is a structural schematic diagram of a stroboscopic ladder lighting defect detection system that adds light source 3 to light source N for supplementary light according to the embodiment of the present invention. Among them, each component is: first camera 201, second camera 202, first light source 203, second light source 204, measured object 205, encoder 206, PLC controller 207, strobe control unit 104, third light source 209 , the fourth light source 210 , and the Nth light source 211 .

[0157] The first camera and the second camera are line scan cameras; the light source includes at least the first light source and the second light source; the encoder generates a corresponding pulse code signal according to the speed of the mechanical rotation system; the PLC controller is a programmable controller, which detects After reaching the measured object, an enabling signal is generated and provided to the stroboscopic control unit; the stro...

Embodiment 3

[0162] Such as Figure 4 as shown, Figure 4 It is a timing diagram of stroboscopic lighting imaging in the prior art. Wherein, when the period of the horizontal frequency signal is T, the first light source, the second light source, the first camera, and the second camera are used to detect and take pictures of four kinds of product defects under test. It can be seen that in the photo D1C1 of the photo taken in the reflected bright field, the first light source is turned on for T1, and the current value is I1 (the magnitude of the current value corresponds to the intensity of the light of the LED light source); in the photo D2C2 of the photo taken in the dark field of transmission , the second light source is turned on for T2 and current I2; in the photograph D1C2 of the transmitted bright field, the first light source is turned on for T3 and the current is I1; in the reflected dark field photograph D2C1, the second light source is turned on for T4 and the current is I2; It...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com