Convex submarine cable protection pipe

A technology for protecting tubes and submarine cables. It is applied to the installation of cables, cables on floats, and electrical components. It can solve the problems of increasing friction, reducing the protection effect, and reducing the swing amplitude of submarine cables, so as to reduce the swing. Effects of width, light weight of structure, and reduction of material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with specific embodiments.

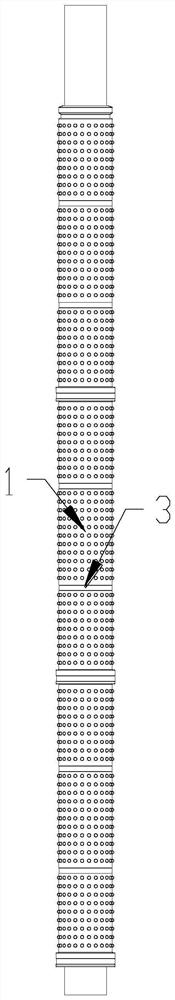

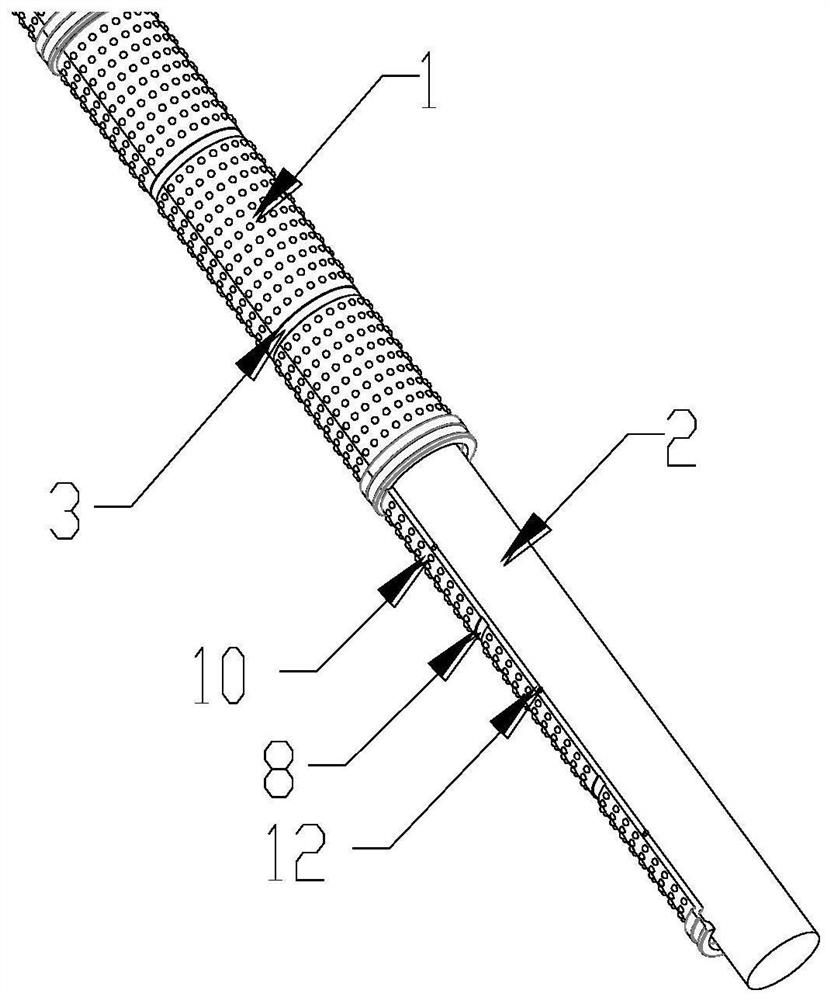

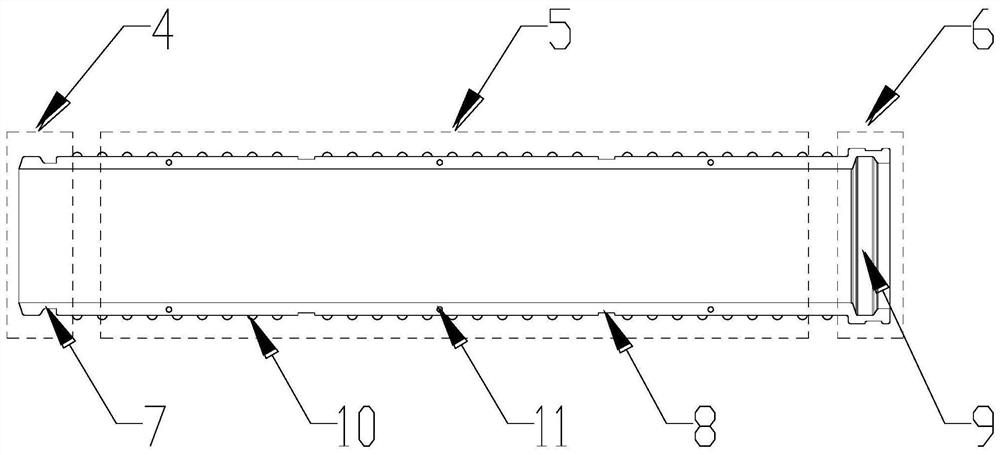

[0018] like Figure 1 to Figure 3 The shown submarine cable protection tube includes a chain structure composed of at least two submarine cable protection tube modules interlocking with each other. Each section of the submarine cable protection tube module is designed as a Huff structure and consists of two symmetrical single structural units. 1 to cooperate with each other, there is a blind hole 11 on the contact surface of the unit, and the positioning pin 12 is inserted into the blind hole to realize the preliminary cooperation of the symmetrical unit 1; and through the groove 8 on the outer wall, place the steel belt and tighten the connection to realize the symmetrical unit 1, so as to realize the wrapping of the submarine cable 2 and achieve the protection function. The single structural unit 1 includes three parts: a head 4, a main body 5 and a tail 6. The head 4 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com