Separation blade structure for fixing motor rotor part and assembling method

A technology for motor rotors and components, applied in the field of baffle structure, can solve the problems of difficult assembly, inconsistent force, easy to cause deflection, etc., and achieve the effect of improving assembly qualification rate, reducing size requirements, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing and embodiment this scheme is further introduced.

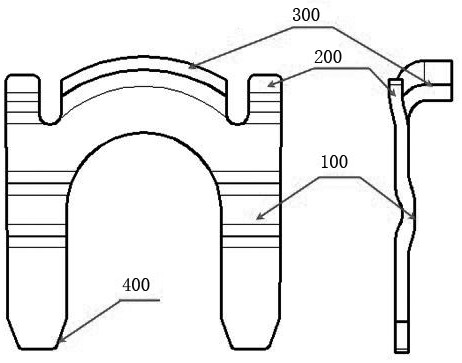

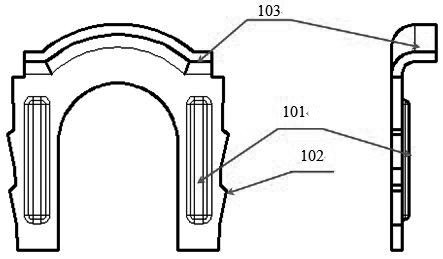

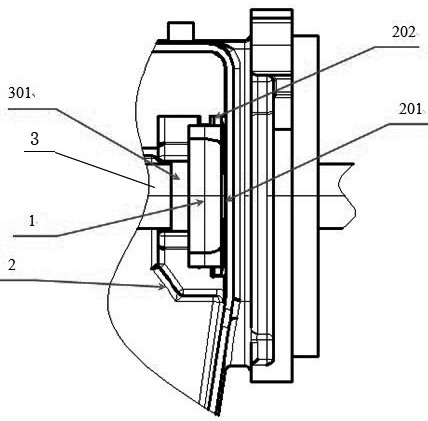

[0022] see figure 1 , image 3 , Figure 4 , a baffle structure for fixing the rotor part of a motor, including arch height 100, independent flanging 200, flip 300 and bevel 400, the baffle is inverted U-shaped, with a transverse arch height of 100 at the front end and a flip at the top The surface is 300, the two sides of the top are respectively provided with independent flanges 200, and the two feet of the bottom are respectively provided with left and right hypotenuses 400; The side 200 is a structure that rises in the opposite direction to the arch height 100, and is distributed on both sides of the block; the independent flanges 200 on both sides are attached to the reducing shell 2, and the arch height 100 is in contact with the bearing 301 of the rotor component. At this time, the independent flanges 200 and the arch height 100 are deformed at the same time, pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com