Industrial dust collector

A technology for industrial vacuum cleaners and dust buckets, applied in vacuum cleaners, suction filters, manufacturing tools, etc., can solve the problems of restricting air flow, the vacuum cleaner cannot work normally and continuously, and the dust and humidity are high, so as to achieve the effect of improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

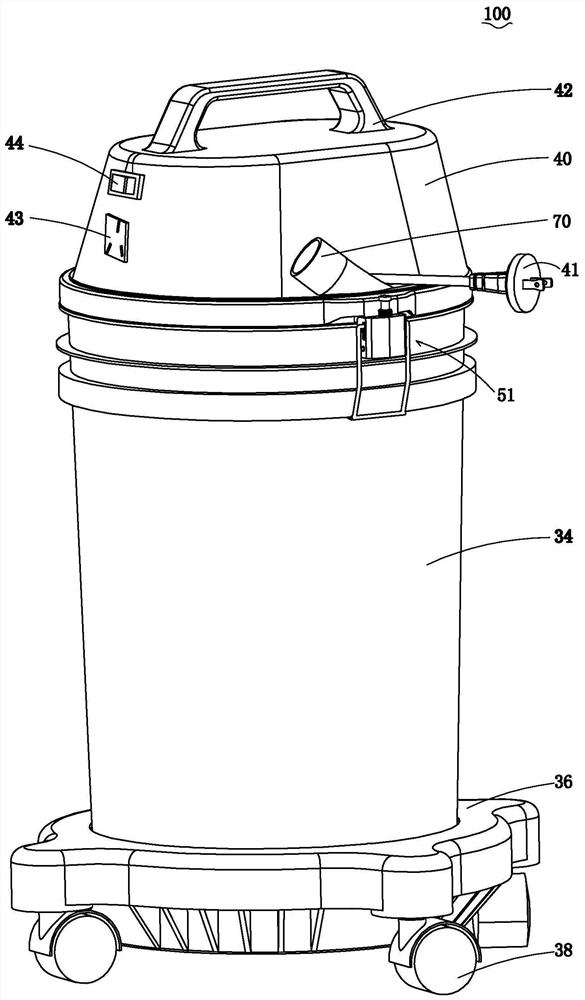

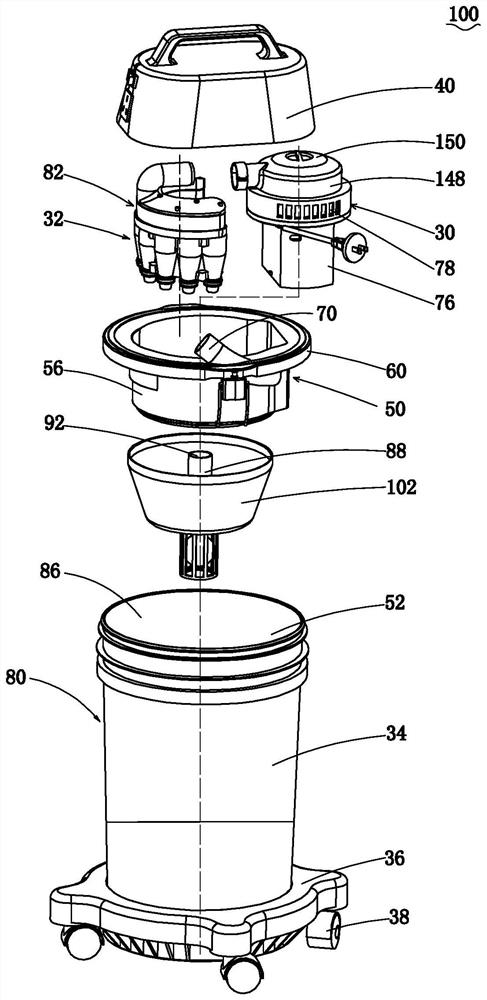

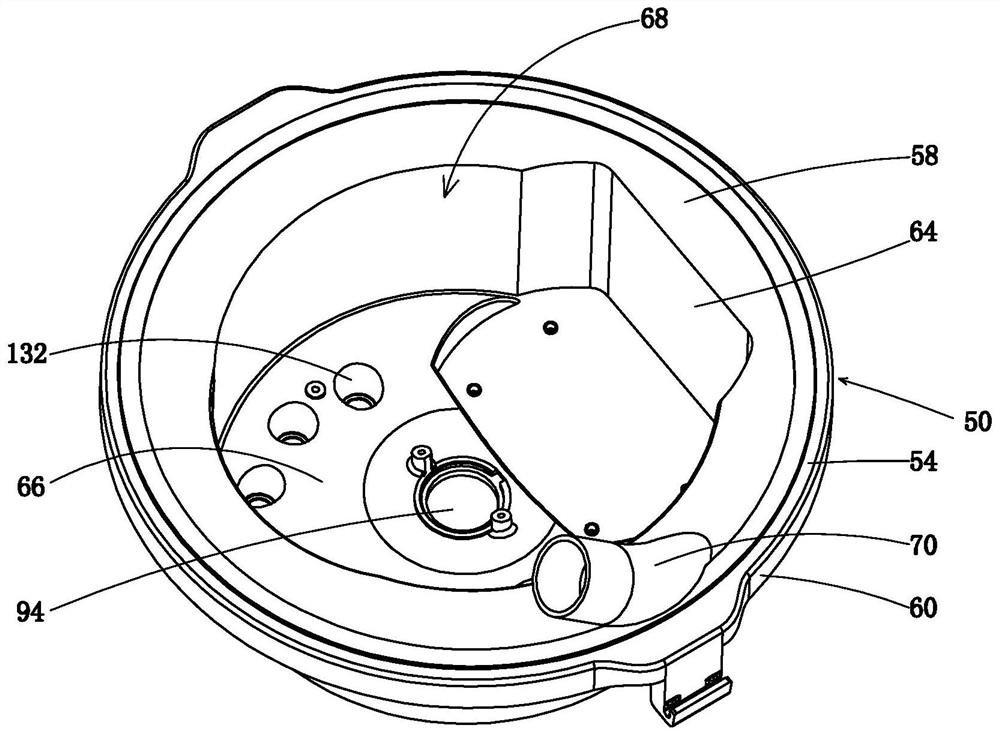

[0056] See figure 1 and figure 2 , the industrial vacuum cleaner 100 includes an airflow generating device 30, a separation device 32 communicating with the airflow generating device 30, and a dust bucket 34 for collecting dust. The lower part of the dust bucket 34 can be installed on the base 36, and a plurality of rollers 38 are arranged below the base 36, so that the vacuum cleaner 100 can be easily moved as required. A protective cover 40 can be provided on the top of the dust bucket 34, and the protective cover 40 can cover the airflow generating device 30 for protecting the airflow generating device 30, and can also be provided with a handle 42 to facilitate the movement of the vacuum cleaner 100. The industrial vacuum cleaner 100 of the present application is only a customary name, and is not limited to its use occasions. The industrial vacuum cleaner 100 can be widely used in various occasions such as rooms and workshops for cleaning work.

[0057] The main switch 4...

specific Embodiment approach 2

[0122] Such as Figure 12 to Figure 13 As shown, the second embodiment of the present invention discloses an industrial vacuum cleaner 200, including an airflow generating device 230, a separating device 232 communicated with the airflow generating device 230, and a dust bucket 234 for collecting dust. The lower part of the dust bucket 234 can be installed on the base 236, and a plurality of rollers 238 are arranged below the base 236, so that the vacuum cleaner 200 can be easily moved as required. A protective cover 240 can be provided on the top of the dust bucket 234 , and the protective cover 240 can cover the airflow generating device 230 to protect the airflow generating device 230 , and can also be provided with a handle 242 to facilitate the movement of the vacuum cleaner 200 .

[0123] The separation device 232 includes a multi-stage separation device including a primary separation device 280 , a secondary separation device 282 and a tertiary separation device 244 . ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap