Cyclization kettle for dehydrating gasified sulfur trioxide

A technology of sulfur trioxide and cyclization, applied in the field of reaction tanks, can solve the problems of poor fluidity of low-temperature coolant and inability to cool down well, and achieve the effects of increasing cooling effect, improving cooling effect and mixing effect, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention clearer, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention. Obviously, the described embodiments It is a part of embodiments of the present invention, but not all embodiments. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without creative efforts fall within the protection scope of the present invention.

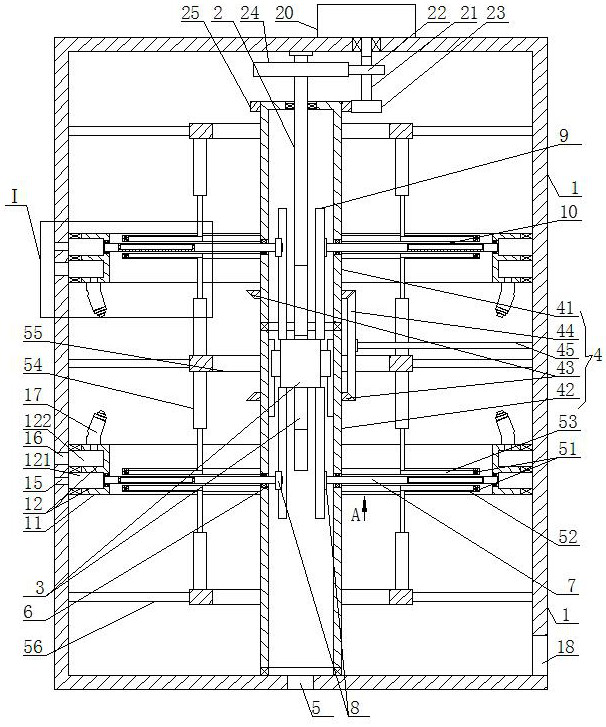

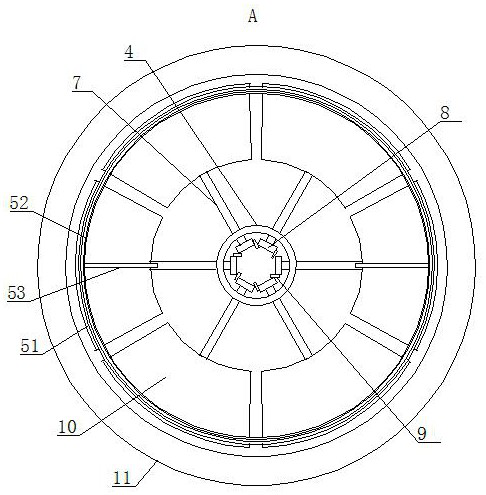

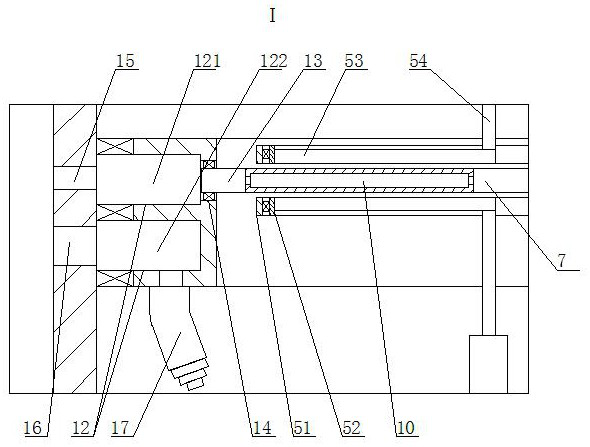

[0015]A ring closure kettle for gasification sulfur trioxide dehydration, as shown in the figure, includes a tank body 1, a coaxial vertical shaft 2 is installed in the tank body 1 for rotation, and the upper end of the vertical shaft 2 and the top of the tank body 1 rotate through bearings connection, the lower end of the vertical shaft 2 is fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com