Low-impedance activated carbon for automobile carbon tank as well as preparation method and application thereof

A technology of activated carbon and low impedance, applied in the field of activated carbon, can solve the problems of poor adsorption performance and low ventilation impedance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

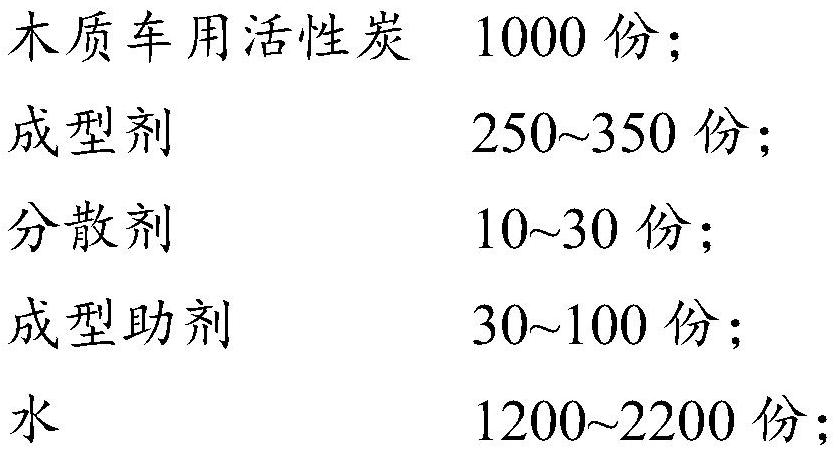

[0034] The present invention also provides a method for preparing activated carbon for low-impedance automobile canisters described in the above technical solution, comprising the following steps:

[0035] Kneading activated carbon for wooden vehicles, forming agent, dispersant, forming aid and water to obtain slurry;

[0036] placing the slurry in a mold and extruding to obtain a green body;

[0037] The green body is sintered to obtain activated carbon for low-resistance automobile canisters;

[0038] The activated carbon for the low-resistance automobile canister is a cylinder with through holes.

[0039] In the invention, activated carbon for wooden vehicles, forming agent, dispersant, forming auxiliary agent and water are kneaded to obtain slurry. In the present invention, the kneading is preferably carried out in a mud mixer, the kneading temperature is preferably 20-40°C, and the kneading time is preferably 30°C. The invention fully mixes the activated carbon for woo...

Embodiment 1

[0047] Put 1000g activated carbon for wooden vehicles (particle size is 75 μm), 300g forming agent attapulgite, 20g dispersing agent polyvinyl alcohol, 50g forming auxiliary carboxymethyl cellulose and 1500g water in the mud mixer, at 30 ℃ Carry out kneading 2h under, obtain slurry;

[0048] The slurry is placed in a porous stainless steel mold, and extruded in a high-pressure vacuum screw extruder at an extrusion speed of 30 cm / min to obtain a green body;

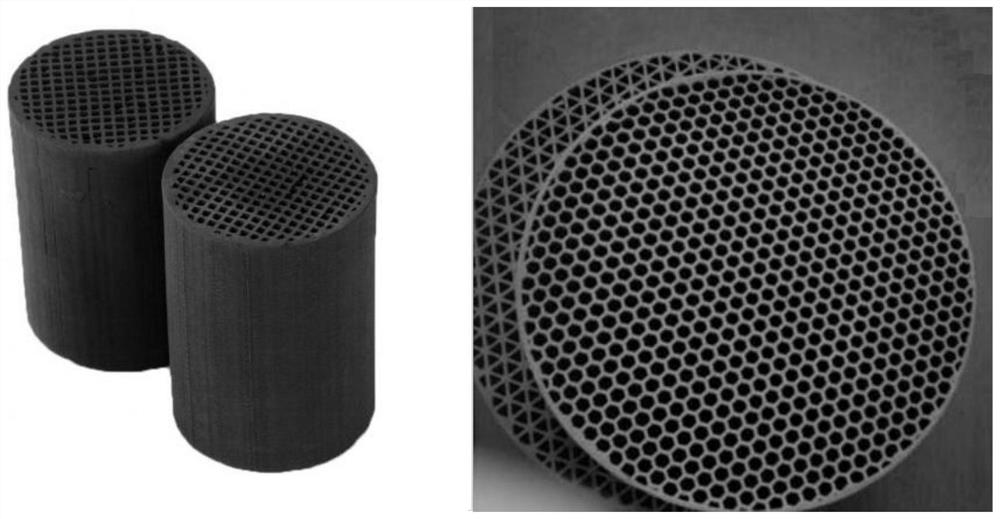

[0049] The green body is pre-dried in a tunnel hot air furnace, then cut into activated carbon of required size, and sintered at 700°C for 2 hours to obtain the following: figure 1 Activated carbon for low impedance automotive canisters with through holes shown;

[0050] The activated carbon used for the low-impedance automobile carbon canister is a cylinder, with a diameter of 35mm and a height of 50mm; the cross-section of the through hole is circular, and the diameter of the through hole is 1mm; the number of channels ...

Embodiment 2

[0053] Put 1000g activated carbon for wooden vehicles (particle size is 75 μm), 250g forming agent attapulgite, 10g dispersing agent polyvinyl alcohol, 50g forming auxiliary carboxymethyl cellulose and 1500g water in the mud refining machine, under the condition of 30 ℃ Carry out kneading under 2 hours, obtain slurry;

[0054] The slurry is placed in a porous stainless steel mold, and extruded in a high-pressure vacuum screw extruder at an extrusion speed of 30 cm / min to obtain a green body;

[0055] The green body is pre-dried under the condition of a tunnel hot air furnace, then cut into activated carbon of required size, and sintered for 2 hours under a nitrogen protective atmosphere at 700°C to obtain a low-impedance activated carbon for automobile canisters with through holes;

[0056] The activated carbon for the low-impedance automobile carbon canister is a cylinder, with a diameter of 35mm and a height of 100mm; the cross-section of the through hole is circular, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Cross-sectional area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com