Typical cabin section tapping turnover platform

A technology of turning platforms and cabins, which is applied in the direction of thread cutting machines, metal processing equipment, manufacturing tools, etc., can solve the problems that affect the progress of typical cabin processing, affect the processing progress, reduce tapping efficiency, etc., and improve the tapping environment , Speed up the processing progress and improve the tapping efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

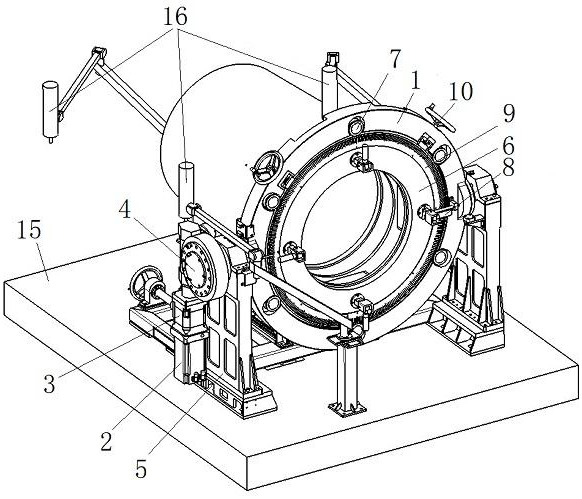

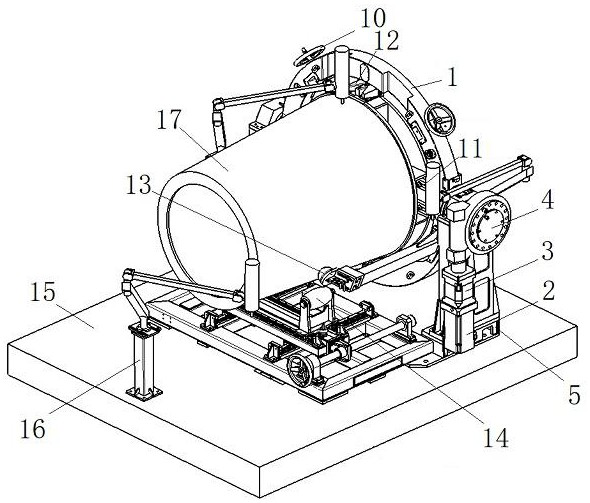

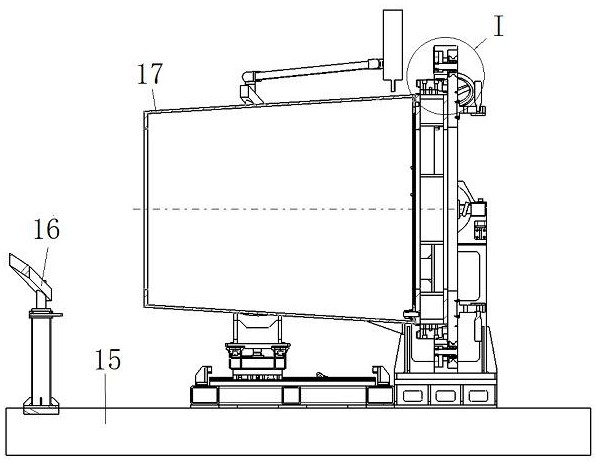

[0015] Such as Figure 1-4 As shown, the present invention is a typical cabin section tapping and turning platform, including a horizontal turning platform 1, a horizontal turning mechanism is provided on the circumferential surface of the horizontal turning platform 1, and an axial turning mechanism is arranged at the center of the horizontal turning platform 1. Rotation mechanism, the horizontal rotation mechanism includes a servo motor 2, a reducer 3, a slewing support 4, the servo motor 2 is installed on the base 15, the servo motor 2 is connected with the slewing support 4 through a reducer 3, the slewing The support 4 is installed on the base 15 through the bracket 5, the slewing support 4 is connected with the horizontal turning platform 1, the servo motor 2 drives the slewing support 4 to rotate through the reducer, and the rotating shaft of the slewing support 4 rotates to drive the horizontal turning on the rotating shaft The table 1 rotates to achieve the horizontal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com