Machining process for thin-wall annular part of IC equipment

A processing technology and parts technology, which is applied in the processing technology field of thin-walled ring parts of IC equipment, can solve problems such as difficulty in ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] combined with Figure 1-4 The notations describe the invention in detail.

[0021] The present invention relates to a processing technology for thin-walled annular parts of IC equipment. The structure of the thin-walled annular part has strict requirements on thin plate welding and dimensional accuracy, and is a very typical welded special-shaped part.

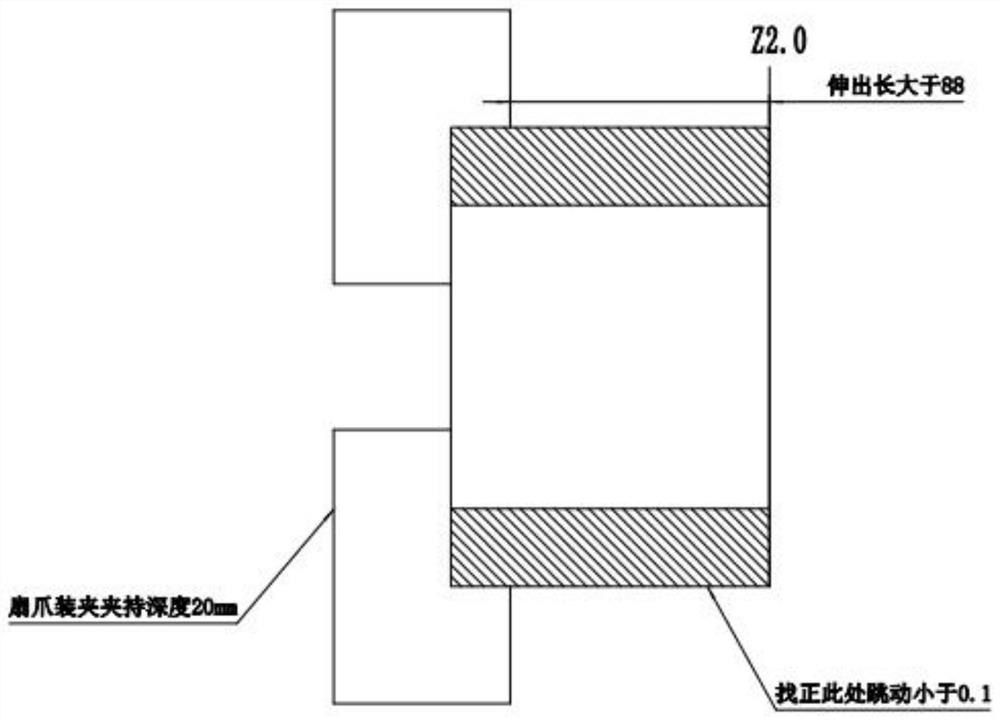

[0022] The first step: clamping, the clamping depth is guaranteed to be about 20mm to ensure the clamping strength, and the extension is 88mm to ensure the follow-up processing process. And find out that the beating of the outer ring is 0.1. The inner diameter and outer circle of the lathe rough machining parts. Leave a margin of 2mm for the inner and outer diameters. One piece of material can process the length of 5 parts, and rough machine the end face.

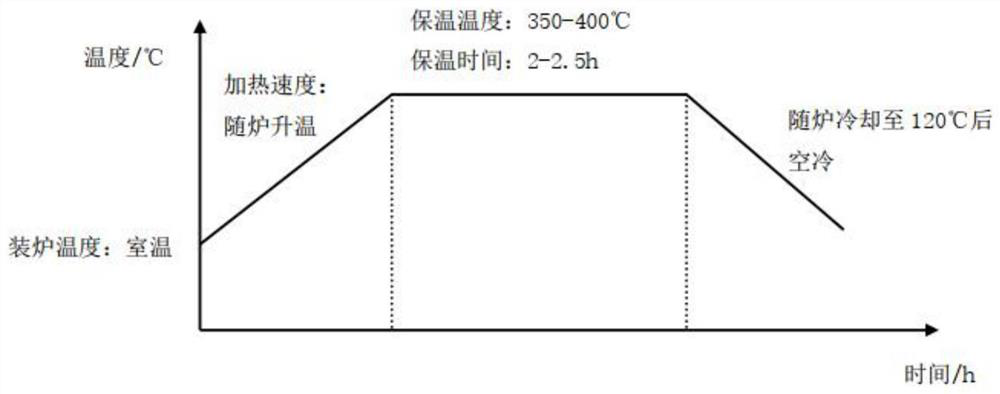

[0023] The second step: heat treatment process, heat to 350-400 ℃, keep warm for 2-2.5h; cool to 120 ℃ with the furnace, and then use air cooling.

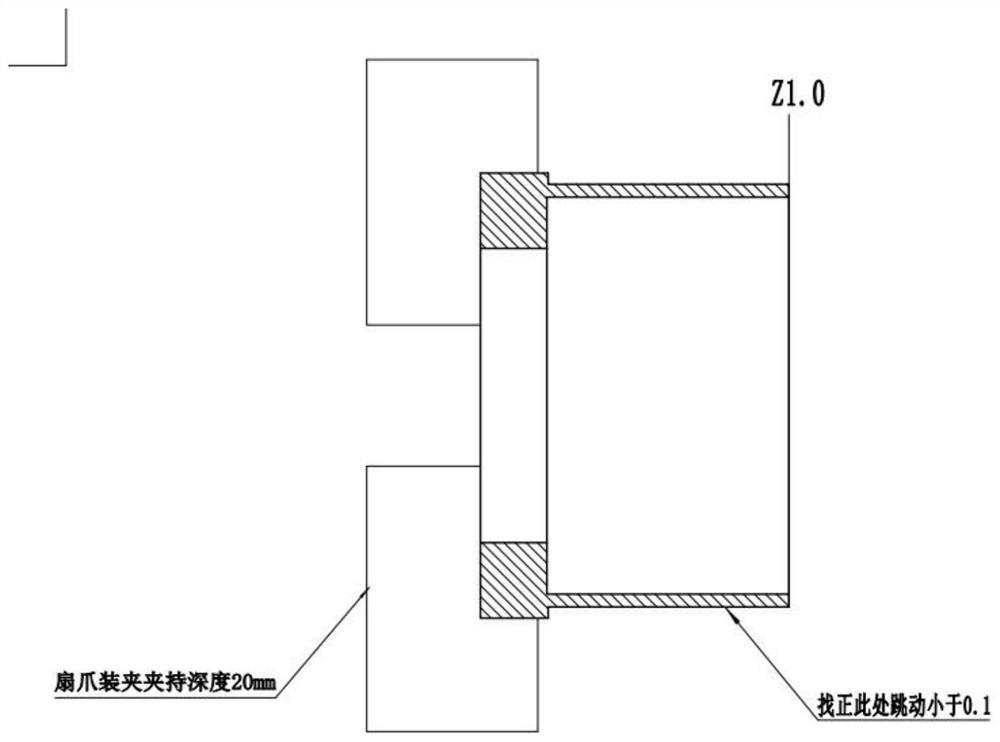

[0024] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com