Method for manufacturing and installing improved handlebar and improved brake handle of electric vehicle

A manufacturing method and technology for brake levers, which are used in transportation and packaging, bicycle accessories, bicycle brakes, etc., can solve the problems of human injury, unbearable, bulging immediately above the tibia, easy to hurt people's legs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

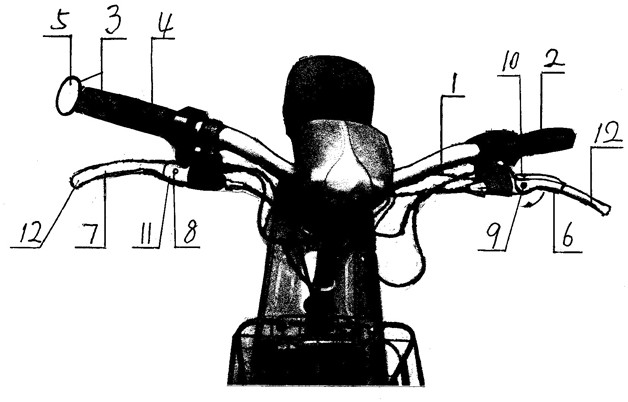

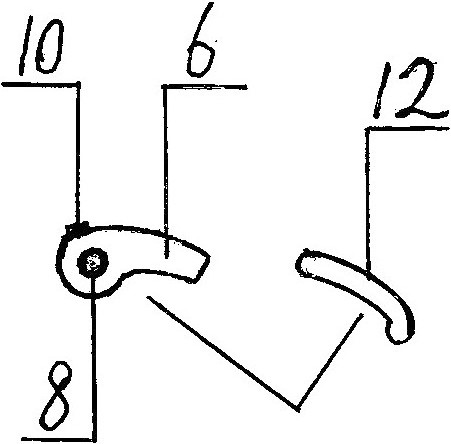

[0025] Such as figure 1 , 2 As shown in , 3, a technical scheme of manufacturing and installation method of an improved handlebar and brake handle of an electric vehicle is provided, so as to solve the technical defect that the existing electric vehicle is easy to injure a person's leg;

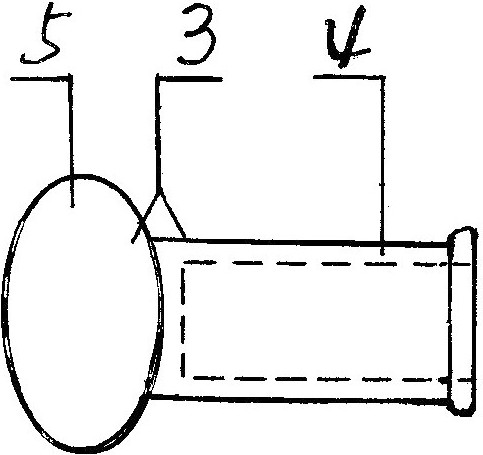

[0026] The technical characteristics of this manufacturing method are: firstly, carry out technical improvement on the two ends of the existing handlebar 1, according to the existing two ends of the handlebar 1 body (excluding the handle part in the prior art) are hollow circular tubes Features, the manufacturing method used for improvement is: put a section of round tube 4 with a bayonet (buckle) or thread structure into the round tube at both ends of the handlebar 1 after removing the head 3 of the handlebar 2 (the round tube of the round tube) The internal thread is not shown in the figure), the round pipe 4 of the buckle or thread structure adopts the technical means and equipment of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com