Bridge construction bridge deck dreg cleaning and removing equipment

A bridge construction and dross technology, which is applied in bridge construction, bridges, bridge materials, etc., can solve problems such as inconvenient operation, tire wear, and many working procedures, and achieve the effect of convenient cutting and filling the gap in the market

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

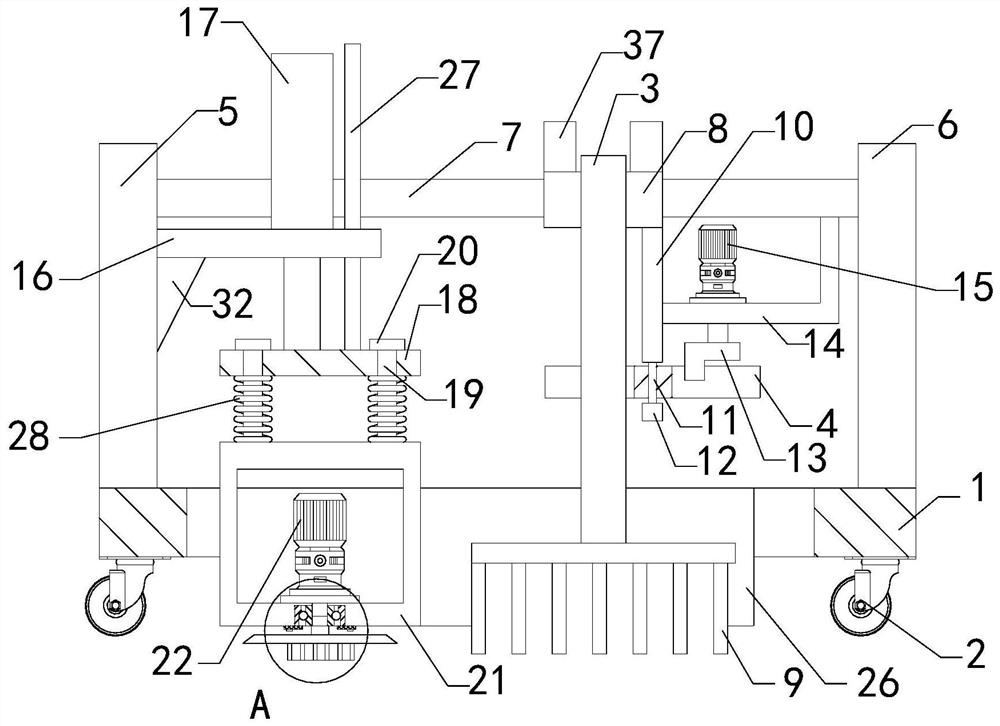

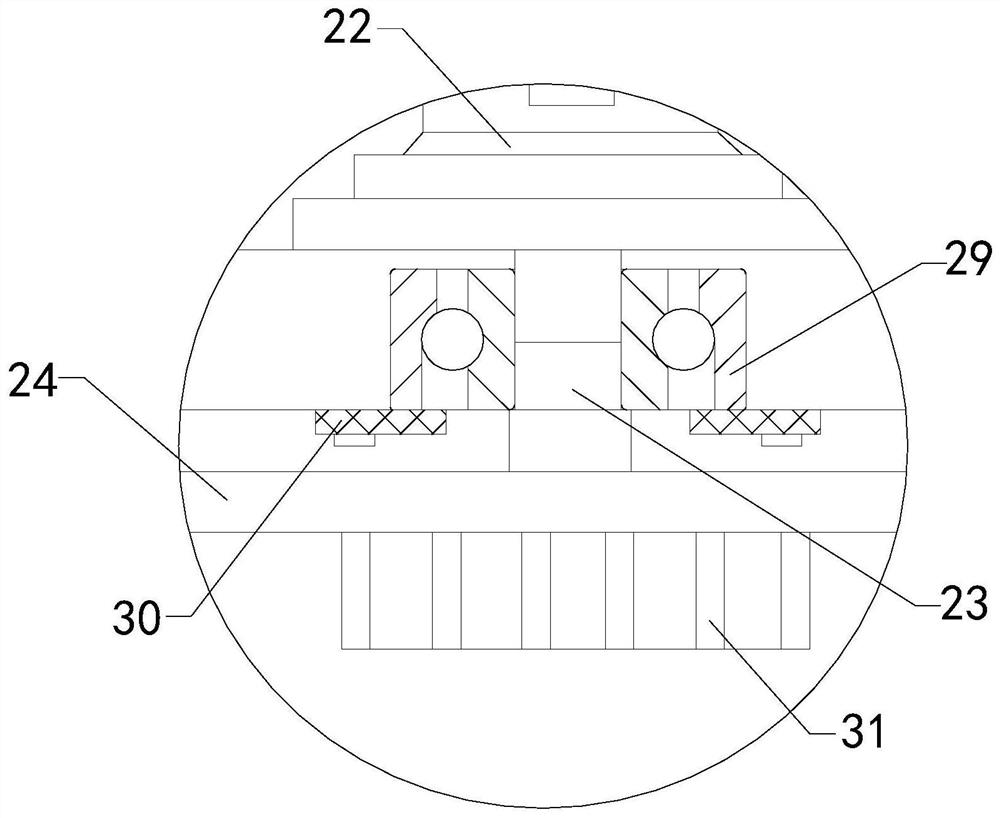

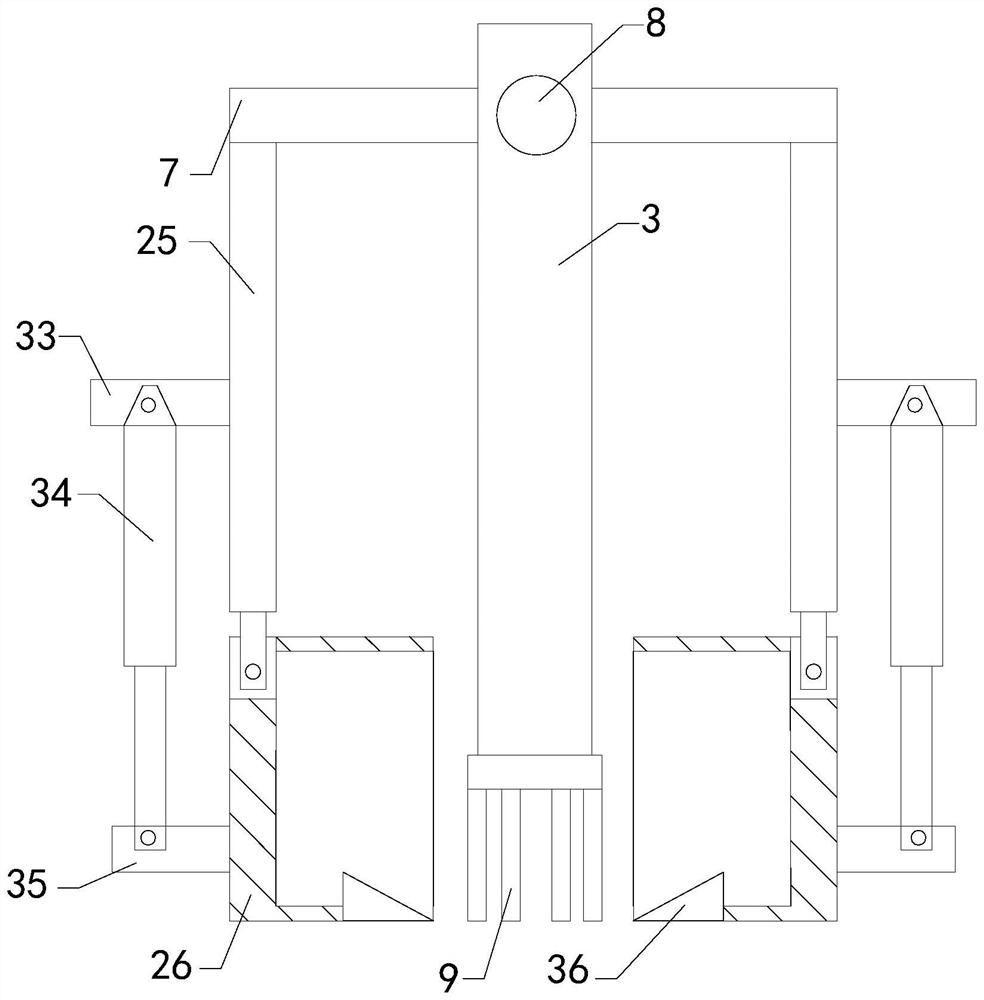

[0027] see Figure 1-5, a bridge construction bridge deck dross cleaning equipment, including a base 1, a rotating plate 3 and a shift fork 4, the middle of the base 1 is provided with a penetrating square hole, the four corners of the bottom of the base 1 are fixedly connected with casters 2, the base The top left part and the top right part of 1 are respectively fixedly connected with a left support plate 5 and a right support plate 6, and a top plate 7 is fixedly connected between the upper parts of the opposite ends of the left support plate 5 and the right support plate 6, and the middle part of the top plate 7 is fixedly connected There is a supporting shaft 8, and the middle part of the top plate 7 is provided with a step-off hole corresponding to the rotating plate 3. The top left part and the top right part of the supporting shaft 8 are fixedly connected to the limit block 37, and the upper part of the rotating plate 3 and the The middle part of the peripheral outer w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com